Method for preparing (‑) gamma lactam by using members of cysteine hydrolase family

A technology of cysteine and γ-lactam, which is applied in the field of enzyme engineering and can solve the problem of no patent report for the cysteine hydrolase family

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

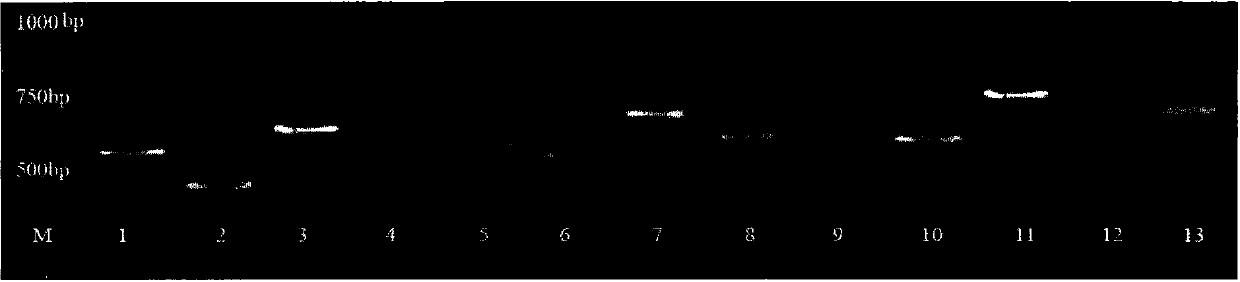

[0073] Embodiment 1 The acquisition of the cysteine hydrolase gene of 13 kinds of microbial sources involved in the present invention

[0074] (1) Acquisition of bacterial genomic DNA

[0075] Purchase nitrogen-fixing rhizobia (Azorhizobium caulinodans 1.2548), Bacillus pumilus 1.326, Escherichia coli 1.359, Lactobacillus lactis (Lactococcus lactis 1. .2030), Methylobacterium extorquens4.1476, Pseudomonas aeruginosa1.228, Ralstonia pickettii1.1759, Sinorhizobium fredii1. 535), Streptococcus aureus (Staphylococcus aureus1.363), the bacterial strain ampoule tube of Vibrio parahaemolyticus (Vibrio parahaemolyticus1.1997), add 1mL culture medium after the mouth of the pipe is smashed, and the culture medium is published according to the Microbial Strains Preservation Management Committee The methods in the "Catalogue of Strains" are formulated for different strains. Then, the suspension of the bacterial strain was inserted into 100 mL of the same medium for culture, and the sh...

Embodiment 2

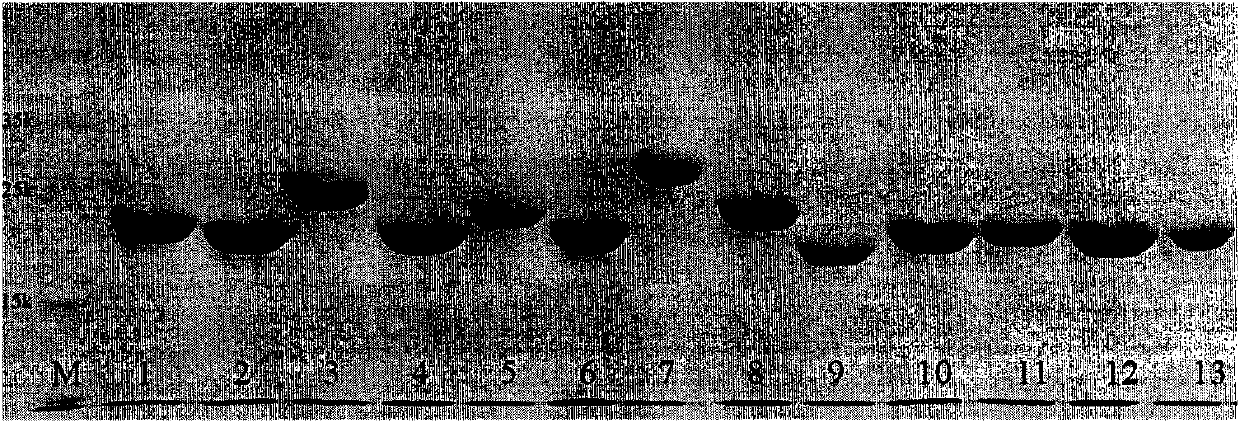

[0093] Example 2 Expression and purification of recombinant cysteine hydrolase protein

[0094] The constructed plasmid pET**ch was introduced into Escherichia coli E.coil BL21(DE3) by electroporation to obtain the transformant E.coil BL21(pET**ch). Inoculate the transformant into a test tube of LB liquid medium (containing kanamycin), culture overnight at 37°C, and transfer to 400 mL of LB liquid medium (containing kanamycin) at a transfer rate of 1%. , cultured at 37°C, and when the OD value was 0.6-0.8, IPTG with a final concentration of 1 mM was added for induction culture for 3 hours, and the cells were collected by centrifugation. Suspend the bacteria in the binding buffer (50mM TrisHCl, pH8.0, 20mM imidazole, 50mMNaCl), perform ultrasonic disruption (300W, ultrasonic 3 seconds, interval 1 second, 90 cycles in total), centrifuge at 14000RPM, and collect the supernatant , the supernatant was added to 1 mL of nickel affinity column (Novogen), combined and washed with 5 ...

Embodiment 3

[0096] The immobilization of embodiment 3 cysteine hydrolase

[0097] The purified protein was immobilized by sodium alginate method. The immobilization method was as follows. Add 0.3 g of sodium alginate (purchased from Bailingwei Company) to 10 mL of water and heat it to 121 ° C to completely dissolve it. Cool to 30°C, add cysteine hydrolase dissolved in pH 7.0 phosphate buffer, the concentration of cysteine hydrolase in the sodium alginate solution is 4g / L, stir the mixture slightly Mix, carefully drop the mixture into ice-cold 0.1mol / L CaCl with a syringe 2 1.5mol / L boric acid solution, the sodium alginate and CaCl 2 The molar ratio of the immobilized enzyme was controlled at 23:10, and the immobilized enzyme was suspended in the above boric acid solution for 3 hours, keeping the temperature at 4°C. After immobilization, the immobilized enzyme was collected by filtration, washed with distilled water and stored in a refrigerator at 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com