Flame-retardant water-based emulsion for coating glass fiber sleeve and preparation method of emulsion

A glass fiber sleeve, water-based emulsion technology, applied in coatings, fire-retardant coatings, etc., can solve the problems of poor mechanical properties and water resistance, limited flame retardant properties, easy to catch fire, etc., and achieve excellent mechanical properties and flame retardant properties, The effect of good electrical insulation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

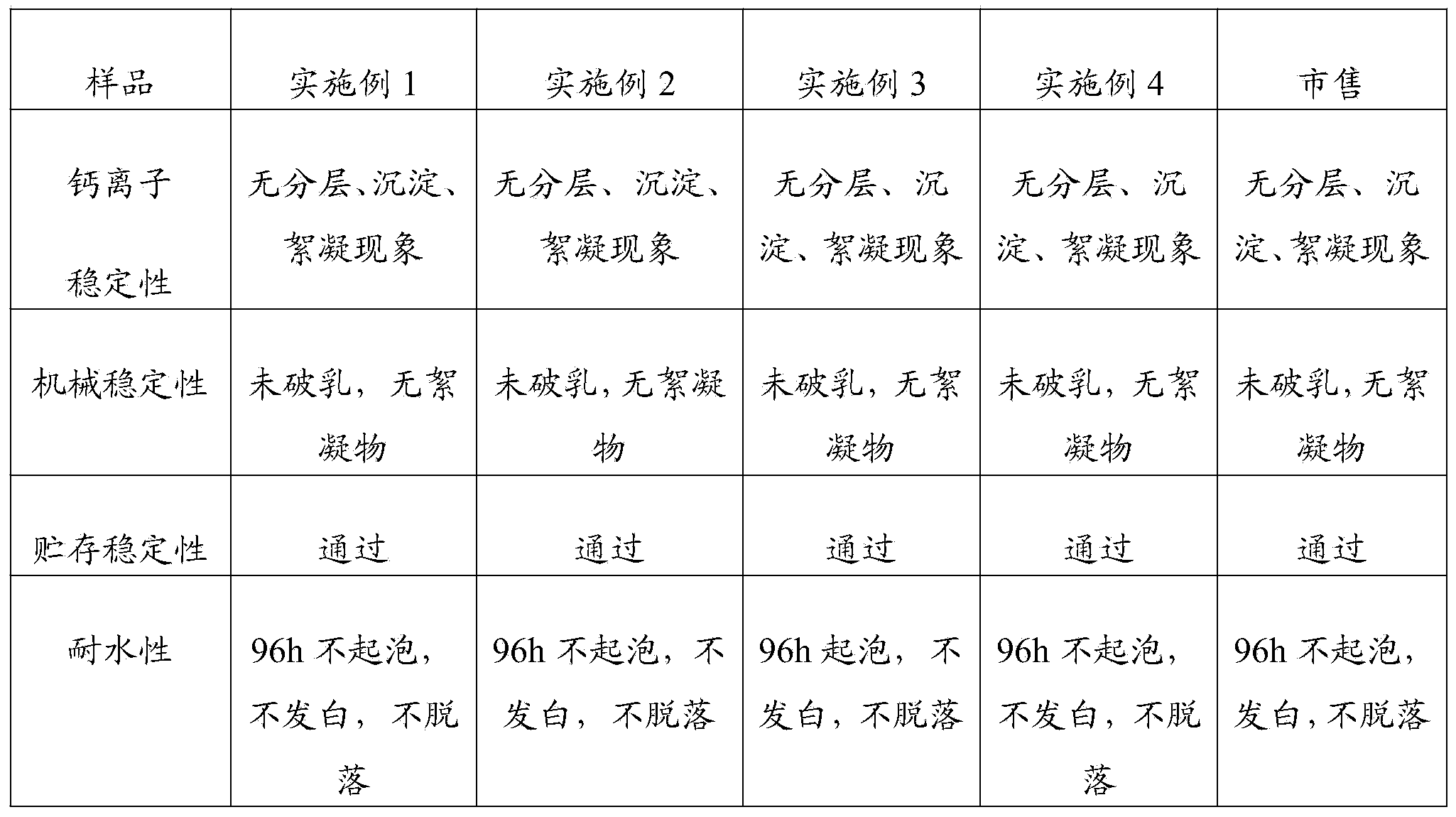

Examples

Embodiment 1

[0034] Prepare the flame-retardant aqueous emulsion for coating the glass fiber sleeve, comprising the following steps:

[0035] Add 45g of isooctyl acrylate, 15.6g of ethyl acrylate, 31.35g of methyl methacrylate, 17.13g of styrene, 28.86g of tribromophenyl methacrylate, and 4.05g of hydroxyethyl methacrylate into a mixture containing 0.6g of alkene Propoxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate is pre-emulsified in 44g water to obtain pre-emulsion A;

[0036] Mix 22g of octamethylcyclotetrasiloxane with 3g of methacryloxypropyl trimethoxysilane to obtain organosilicon monomer;

[0037]Mix 0.55g of 20% trifluoromethanesulfonic acid aqueous solution with 0.4g of allyloxy hydroxypropyl sulfonate and 129.5g of water to obtain a mixed solution. After stirring evenly, the temperature is raised to 65°C, and silicone is added dropwise Monomer, the dropping time is 2.5h, add 2.5g potassium persulfate aqueous solution (mass concentration is 4%), drop pre-emu...

Embodiment 2

[0040] Prepare the flame-retardant aqueous emulsion for coating the glass fiber sleeve, comprising the following steps:

[0041] Add 62.2 g of butyl acrylate, 13.5 g of methyl methacrylate, 13.4 g of styrene, 20.7 g of 2,4,6-tribromophenyl allyl ether, and 4.17 g of hydroxyethyl methacrylate into a mixture containing 1.5 g of alkene Propoxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate is pre-emulsified in 32g water to obtain pre-emulsion A;

[0042] Mix 19g of octamethylcyclotetrasiloxane with 6g of vinyltriethoxysilane to obtain organosilicon monomer;

[0043] Mix 0.2g of 20% trifluoromethanesulfonic acid aqueous solution with 1.97g of allyloxy hydroxypropyl sodium sulfonate and 95.8g of water to obtain a mixed solution. After stirring evenly, heat up to 80°C, and add silicone Monomer, the dropping time is 1h, add 5.56g potassium persulfate aqueous solution (mass concentration: 3%), after the dropwise addition, keep it warm at 85°C for 2 hours, cool down...

Embodiment 3

[0046] Prepare the flame-retardant aqueous emulsion for coating the glass fiber sleeve, comprising the following steps:

[0047] 85g of isooctyl acrylate, 25g of ethyl acrylate, 38g of methyl methacrylate, 45g of styrene, 57.5g of 2,4,6-tribromophenylmaleimide, 2.24g of N-methylolacrylamide Add and carry out pre-emulsification in 61g water containing 6g allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate, obtain pre-emulsion A;

[0048] Mix 24g of dodecamethylcyclohexasiloxane with 4g of vinyltriethoxysilane to obtain organosilicon monomer;

[0049] Mix 1 g of 20% trifluoromethanesulfonic acid aqueous solution with 6.88 g of allyloxy hydroxypropyl sulfonate and 183.2 g of water to obtain a mixed solution. After stirring evenly, the temperature is raised to 90 ° C, and organosilicon mono body, the dropping time is 3h, add 10.3g potassium persulfate aqueous solution (mass concentration is 3%), drop pre-emulsion A, drop adding time is 4h, then add dropwise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com