Preparation method of metal-free catalyst for room-temperature efficient catalytic oxidation desulfurization

A catalytic oxidative desulfurization, metal-free technology, used in metal/metal oxide/metal hydroxide catalysts, sulfur preparation/purification, physical/chemical process catalysts, etc. Long process and other problems, to achieve the effect of novel structure, wide source of raw materials and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

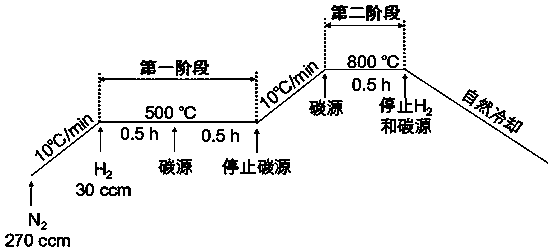

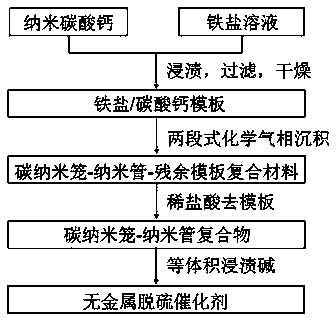

[0042] Such as figure 2 As shown, a method for preparing a metal-free catalyst for efficient catalytic oxidation desulfurization at room temperature of the present invention, the specific preparation process is as follows:

[0043] (1) Disperse 12 g of ferric nitrate in 600 mL of distilled water to obtain an aqueous ferric nitrate solution with a concentration of 20 mg / mL;

[0044] (2) 60 g of nano-calcium carbonate is added in the above-mentioned ferric nitrate aqueous solution, and magnetically stirred for 24 h to make it fully impregnated, and the used nano-calcium carbonate is a small particle with a particle diameter of 20-60 nm;

[0045] (3) above-mentioned impregnation mixture is filtered, and vacuum-dried, obtains the nano-calcium carbonate impregnated iron nitrate;

[0046] (4) Using nano-calcium carbonate impregnated with ferric nitrate as a template, pyridine as a carbon source, inert gas as a protective gas, hydrogen as a reducing gas, and introducing a carbon s...

Embodiment 2

[0059] Such as figure 2 As shown, a method for preparing a metal-free catalyst for efficient catalytic oxidation desulfurization at room temperature of the present invention, the specific preparation process is as follows:

[0060] (1) Disperse 6 g of ferric nitrate in 600 mL of distilled water to obtain an aqueous ferric nitrate solution with a concentration of 10 mg / mL;

[0061] (2) 60 g of nano-calcium carbonate is added in the above-mentioned ferric nitrate aqueous solution, and magnetically stirred for 24 h to make it fully impregnated, and the used nano-calcium carbonate is a small particle with a particle diameter of 20-60 nm;

[0062] (3) above-mentioned impregnation mixture is filtered, and vacuum-dried, obtains the nano-calcium carbonate impregnated iron nitrate;

[0063] (4) Using nano-calcium carbonate impregnated with iron nitrate as a template, a mixture of pyridine and anthracene oil (mass ratio 1:1) as a carbon source, an inert gas as a protective gas, and h...

Embodiment 3

[0070] Such as figure 2 As shown, a method for preparing a metal-free catalyst for efficient catalytic oxidation desulfurization at room temperature of the present invention, the specific preparation process is as follows:

[0071] (1) Disperse 6 g of ferric chloride in 600 mL of aqueous ethanol (the volume ratio of ethanol to distilled water is 1:2) to obtain a ferric chloride solution with a concentration of 10 mg / mL;

[0072] (2) 60 g of nano-calcium carbonate is added in the above-mentioned iron chloride solution, and magnetically stirred for 24 h to make it fully impregnated, and the used nano-calcium carbonate is a small particle with a particle diameter of 20-60 nm;

[0073] (3) above-mentioned impregnation mixture is filtered, vacuum-dried, obtains the nano-calcium carbonate impregnated ferric chloride;

[0074](4) Using nano-calcium carbonate impregnated with ferric chloride as a template, pyridine as a carbon source, inert gas as a protective gas, and hydrogen as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com