Functional peptide protein powder, and preparation method and applications thereof

A technology of functional peptide and protein powder, which is applied in the field of animal-derived protein feed preparation, can solve problems such as easy moisture absorption, large composition changes, and affecting feeding effects, so as to increase the content of amino nitrogen, increase the content of protein, and The effect of improving the hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

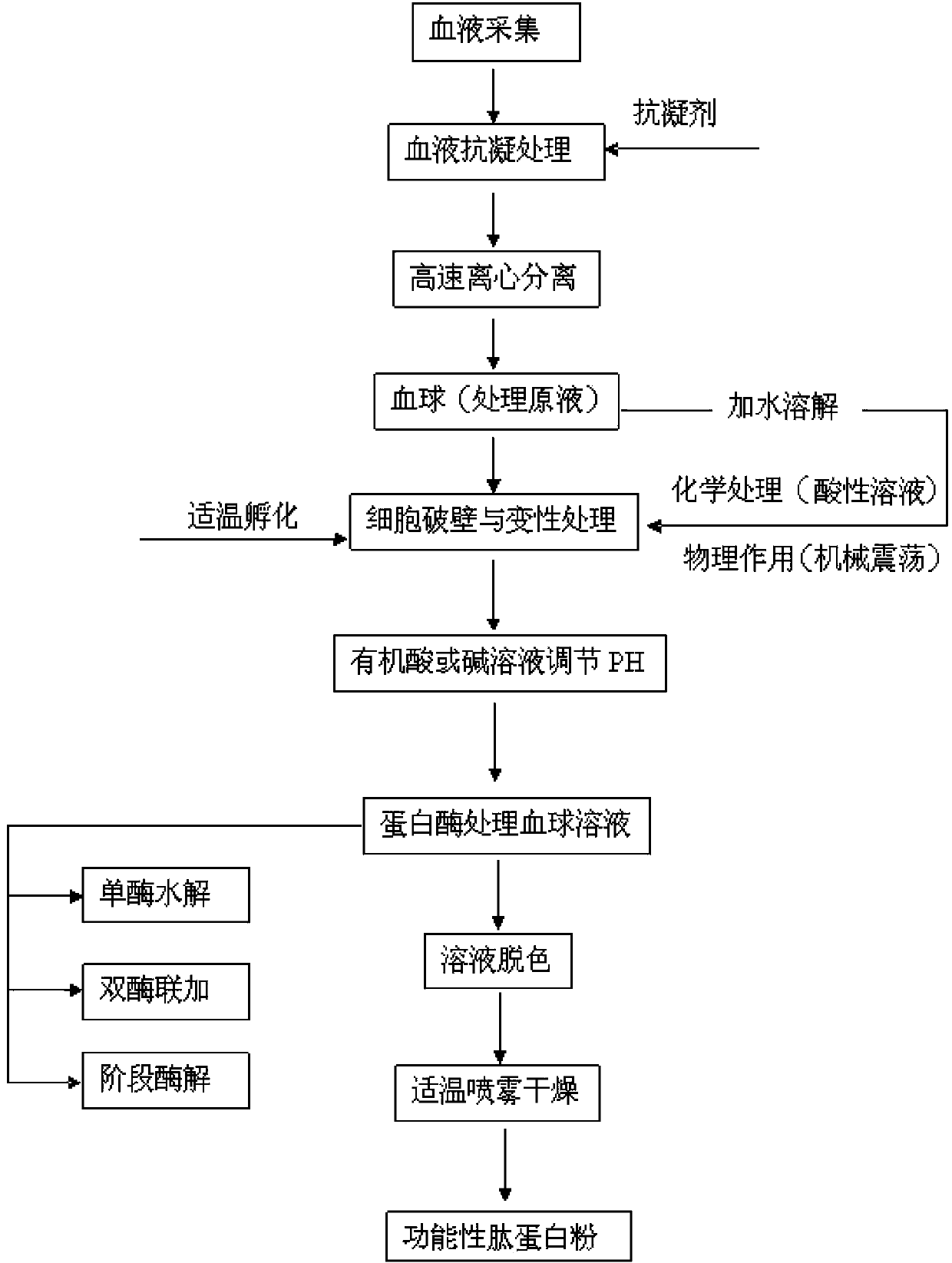

Method used

Image

Examples

preparation example Construction

[0099] ②Preparation of serine standard solution: 50mg of serine was dissolved in 500ml of deionized water (0.9516meqv / L).

[0100] ③Preparation of sample solution: Xg sample is dissolved in 100ml deionized water, X is 0.1-1.0g sample containing 8%-80% protein.

[0101] ④Standard measurement: Add 400μL of serine standard solution into a stoppered test tube containing 3mL of OPA reagent, shake well, react accurately at room temperature for 2min, and then measure its absorbance at 340nm with a UV spectrophotometer.

[0102] ⑤ Blank measurement: Add 400 μL deionized water to a stoppered test tube containing 3 mL of OPA reagent, shake well, react accurately at room temperature for 2 min, and then measure its absorbance at 340 nm.

[0103] ⑥Sample detection: Add 3 mL of OPA reagent to 0.4 μL of the sample to be tested and mix well, let it stand at room temperature for 2 minutes, and then measure its absorbance at 340 nm.

[0104] ⑦Calculation:

[0105]

[0106]

[0107] In t...

Embodiment 1

[0119] Example 1 Preparation of functional peptide protein powder E-1

[0120] (1) Preparation of blood cells: Collect fresh duck blood from the slaughterhouse in a safe and hygienic way, and then add 0.6% sodium citrate to the total blood weight to prevent blood coagulation. Transport the duck blood with sodium citrate to the processing plant in the shortest possible time, and centrifuge it with a high-speed centrifuge at a speed of 14,000r / min for 10 minutes. At this time, the blood is divided into upper and lower layers, and the upper layer is light yellow plasma. , stored for other purposes; the lower layer is dark red viscous blood cells.

[0121] (2) Cell wall breaking: add water and hydrochloric acid solution with a concentration of 0.25mol / L to the blood cells obtained by centrifugation to prepare blood cell dilution, the mass ratio of hydrochloric acid solution, blood cells, and water is 1:4:5, and then make the substrate The concentration was maintained at 15g / 100mL...

Embodiment 2

[0128] Example 2 Preparation of functional peptide protein powder E-2

[0129] (1) Preparation of blood cells: Collect fresh duck blood from the slaughterhouse in a safe and hygienic way, and then add 0.8% sodium citrate to the total blood weight to prevent blood coagulation. Transport the duck blood with sodium citrate to the processing plant in the shortest possible time, and centrifuge it with a high-speed centrifuge at a speed of 16,000r / min for 8 minutes. At this time, the blood is divided into upper and lower layers, and the upper layer is light yellow plasma. , stored for other purposes; the lower layer is dark red viscous blood cells.

[0130] (2) Cell wall breaking: add water and hydrochloric acid solution with a concentration of 0.05mol / L to the blood cells obtained by centrifugation to prepare blood cell dilution, the mass ratio of hydrochloric acid solution, blood cells, and water is 1:3:6, and then make the substrate The concentration was maintained at 11.5g / 100m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com