4% functional non-antibiotic piglet premix

A piglet premix and functional technology, applied in animal feed, animal feed, application, etc., can solve the problems of synergistic effect and effect variation of probiotics and chitosan oligosaccharides, which are rarely studied, and achieve the reduction of diarrhea rate and feed meat The effect of lower ratio and improved growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A 4%functional non-anti-piglet pre-mixture formula, consisting of the following weights: Astragalus 10-20, Coptis chinensis 10-20, Baitou 8-12, glycotic candy 0.3-2, shell oligosaccharides 0.15--3. Salt 1.5, soda 2.5, lysine 98%: 2.5, oxine 2.5, sourerine 1, ethyl oxygenoline 30: 1.25, yeast nucleotide 2.5-12.5, acidic agent 3, sweetener 0.2, Stone powder 2.75, calcium hydrogen phosphate 2.5, sodium glutamate 0.25-1.5, high temperature resistance 5000: 0.25, mold-proof agent 0.2, composite micro-ecological preparation 0.25-1.5, micro-element additive 12.5, vitamin additive 2.5, lympite powder powder, burpestone powder5-20.

[0024] The composite micro-ecological preparation contains 10 billion CFU / g, 5 billion CFU / g, lactic acid bacteria 3 billion CFU / G, calcium 480mg / kg, and magnesium 9-60mg / kg of lactic acid bacteria.The polymerization of the shell oligosaccharides is 6-8, and the polymerization of glycogen is 4-7.The trace element additives include FE 2750mg per kilogram...

Embodiment 2

[0026] A 4%functional non -anti -piglet pre -mixed feed formula consists of the following weights: astragalus 10, Coptis chinensis 10, Baitou 10, glycogen 1.25, shell oligosaccharide 2.5, salt 1.5, soda 2.5, Lai Lai, Lai98%: 2.5, oxine 2.5, sourerine 1, ethyl oxygenoline 30: 1.25, yeast nucleotide 12.5, acidified agent 3, sweetener 0.2, stone powder 2.75, hydrogen phosphate 2.5, glutamic acid, glutamic acid, glutamic acid, glutamateSodium 1.25, 5000: 0.25 with high temperature resistance, 0.2 anti -mold agent, 1.25 composite micro -ecological preparations, 12.5 of trace element additives, 2.5 vitamin additives, and bloodpill powder 16.1.

[0027] According to the formula, the components are weighed, and the astragalus, Coptis chinensis, and Baitou weng have crushed 60 -mesh screens, mixed with other components evenly to obtain 4%functional non -anti -pig mix.Other embodiment 1.

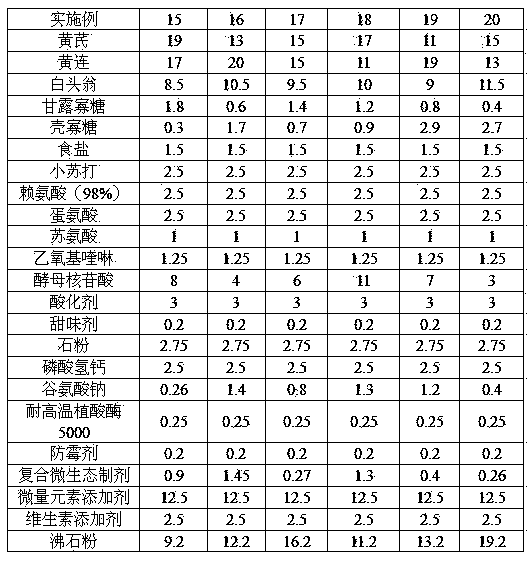

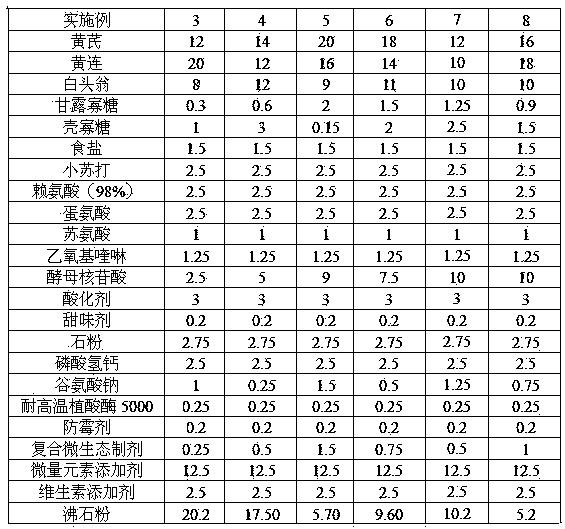

[0028] Example 3-8 4%Functional non-resistant piglet premixing the weight of each raw material ratio r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com