glp-1 derivative particle complex and its preparation method and application

A granular compound, GLP-1 technology, applied in the direction of drug combination, pharmaceutical formula, medical preparations of non-active ingredients, etc., can solve the problems of limiting the breadth and depth of use, reduce the number of injections, avoid side effects, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of embodiment 1γ-PGA

[0043] (1) Preparation of γ-PGA

[0044] Strain activation: Take the frozen Bacillus licheniformis ATCC 9945a out of the -80°C refrigerator, and after thawing, insert it into the seed medium at 1% inoculum size, and culture it at 37°C and 210r / min for 11 hours. Seed medium (LB liquid medium): peptone 1%, NaCl 0.5%, yeast extract 0.5%.

[0045] Fermentation culture: Add the above seed liquid into the fermentation medium according to the inoculum amount of 5%, and cultivate at 37°C and 210r / min for 12h60-72h until the culture liquid becomes viscous. Fermentation medium: maltose 5%, sodium chloride 1%, yeast powder 1%, sodium glutamate 3%, potassium dihydrogen phosphate 0.5%, magnesium sulfate heptahydrate 0.05%.

[0046] Extraction and purification of γ-PGA: Adjust the pH value of the above fermentation culture liquid to 3.0, centrifuge at 10,000 r / min for 30 min to remove bacteria, obtain supernatant, and adjust the pH valu...

Embodiment 2

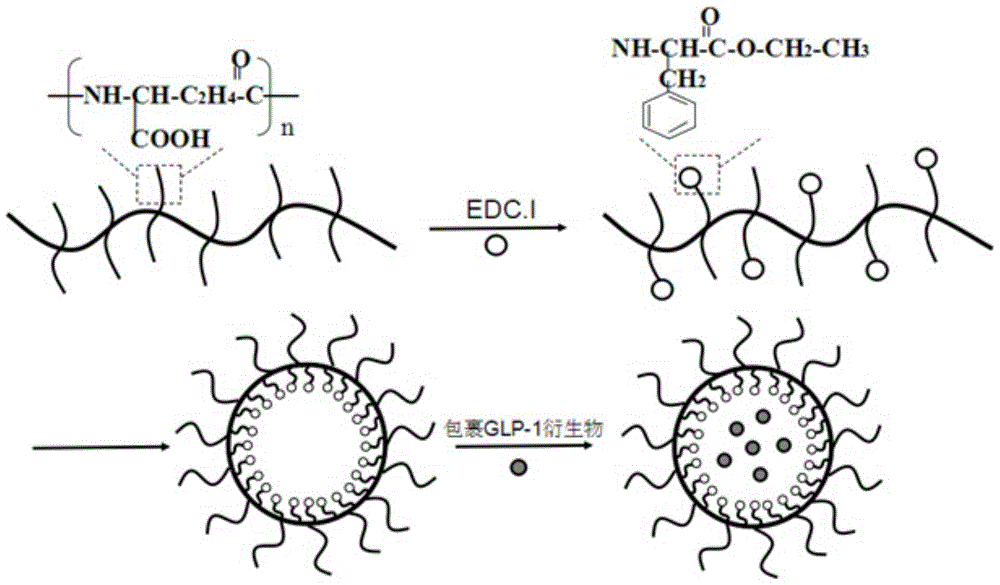

[0049] The preparation of embodiment 2γ-PGA-L-PAE

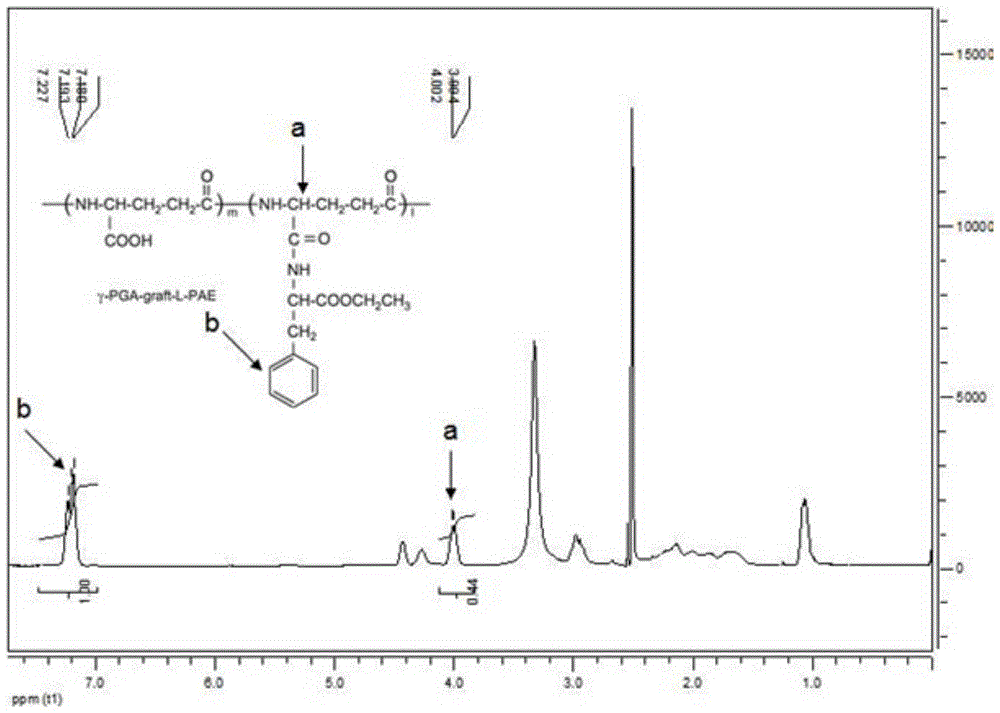

[0050] Weigh 0.1 g of γ-PGA obtained in Example 1 and dissolve it in 50 ml of pure water to prepare a 2% solution, add 2.97 g of EDC.I, shake in a shaker at 37°C and 210 rpm for 15 min, then weigh L- Add 0.96-1.69g of PAE into the reaction system, and continue to react in a shaker at 37°C and 210rpm for 24 hours. A white precipitate was produced in the solution, centrifuged, discarded the supernatant, washed again with ultrapure water, centrifuged and discarded the supernatant, repeated 3 times, and the obtained white precipitate was freeze-dried for 48-72 hours, and the obtained white solid was γ-PGA-L-PAE. For the obtained γ-PGA-L-PAE, carry out proton nuclear magnetic resonance spectrum detection, the solvent is deuterated DMSO, and the spectrum is as follows image 3 As shown, the results show that the characteristic peak of γ-PGA—chemical shift 4.0, and the characteristic peak of L-PAE—chemical shift 8.0 appear in the ...

Embodiment 3

[0051] Preparation and characterization of embodiment 3aGLP-1-NPs

[0052] Preparation method: Dissolve γ-PGA-L-PAE obtained in Example 2 in DMSO to form a 5-40 mg / ml solution. Take 500ul of γ-PGA-L-PAE, slowly add it dropwise to 500ul 0.25~3mg / ml aGLP-1 derivative solution to form a white milky system, centrifuge in a high-speed refrigerated centrifuge at 16000rpm, 4°C for 15min, discard the supernatant , add water again, wash and centrifuge, repeat 3 times, the white precipitate obtained is aGLP-1-NPs, ie aGLP-1-NPs. Wherein, the sequence of aGLP-1 is shown in SEQ ID No:1.

[0053] The aGLP-1-NPs were stained with 1% ammonium molybdate, and the microstructure of the aGLP-1-NPs was observed by transmission electron microscopy, showing a state of round particles with a scale of 100-150nm and uniform distribution, such as Figure 4 Shown; Detected its particle size with a nanometer particle size analyzer, the particle diameter is 140nm, and is a monodisperse system, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com