Preparation method for stable higher fatty alcohol degassing agent

A high-grade fatty alcohol and degassing agent technology, applied in the direction of foam dispersion/prevention, etc., can solve the problems of liquid density fluctuation, environmental pollution accident, and prolonging the reaction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

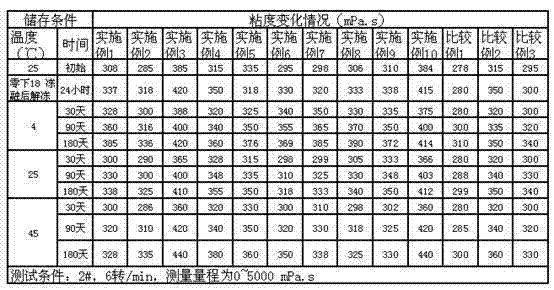

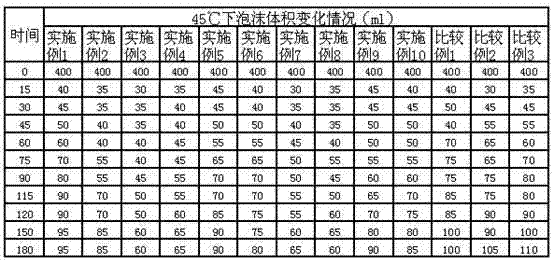

Examples

preparation example Construction

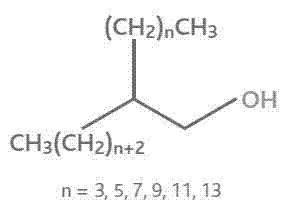

[0078] A preparation method of a stable higher fatty alcohol degassing agent, comprising the following steps:

[0079] Step 1. Put higher fatty alcohol, fatty acid ester, wax, lipophilic surfactant and Guerbet alcohol into the reactor according to the metered proportion, heat up to 75~95°C and keep stirring at 500 rev / min for 2 hours Make sure the system is evenly mixed;

[0080] Step 2, at the same time of step 1, heating the metered proportion of hydrophilic surfactant, deionized water and viscosity control agent to 75~95 ℃ for 2 hours for standby use;

[0081] Step 3. Quickly pour the liquid in Step 2 into the mixture of Step 1, and then emulsify it through a homogenizer at 75 to 95 ° C for 20 to 30 minutes, and then quickly add a metered proportion of biopolysaccharide alcohol and stir for 20 to 60 minutes. minute;

[0082] In step 4, the mixture in step 3 is rapidly cooled to 20-45° C. to obtain a stable high-grade fatty alcohol defoaming and degassing agent.

Embodiment 1

[0084] 230 grams of Ziegler synthesized C 20+ Fatty alcohol, 30 grams of glycerol tristearate, 30 grams of 64# solid paraffin, 1 gram of 2-octyl-dodecanol, and 5 grams of Span 60 were added to the reaction kettle together, heated to 90°C, kept warm and evenly stirred for 1~ 2 hours; add 20 grams of 70% sorbitol, 5 grams of polyacrylic acid viscosity control agent, 0.5 grams of sodium lauryl sulfate, 5 grams of octyl polyoxyethylene ether to 670 grams of deionized water at the same time as the above operations -12 Slowly raise the temperature to 90°C, keep warm and evenly stir for 1 hour, then mix this mixture with the oil phase mixture quickly and emulsify it by a homogenizer for 20 to 30 minutes, then quickly cool to room temperature to obtain fatty alcohol emulsion defoaming and degassing agent 1, The viscosity of the new product tested was 345 mpa.s.

Embodiment 2

[0086] 230 grams of Ziegler synthesized C 20+ Fatty alcohol, 30 grams of triolein, 30 grams of liquid paraffin, 1 gram of 2-octyl-dodecanol, and 5 grams of Span 60 were added to the reaction kettle, heated to 90°C, kept warm and evenly stirred for 1 to 2 hours; Add 20 grams of sorbitol of 70% content to 668 grams of deionized water while the above operations, 10 grams of polyacrylic acid viscosity control agent, 0.5 grams of sodium dodecyl benzene sulfonate, 5 grams of Tween-80 slowly heat up together After reaching 90°C, keep warm and evenly stir for 1 hour. After this mixture is quickly mixed with the oil phase mixture and emulsified by a homogenizer for 20 to 30 minutes, it is rapidly cooled to room temperature to obtain fatty alcohol emulsion defoaming and degassing agent 2, and the viscosity of the new product is tested. is 385 mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com