Sludge dewatering conditioning agent and use method thereof

A sludge dewatering and conditioning agent technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. problem, to achieve the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

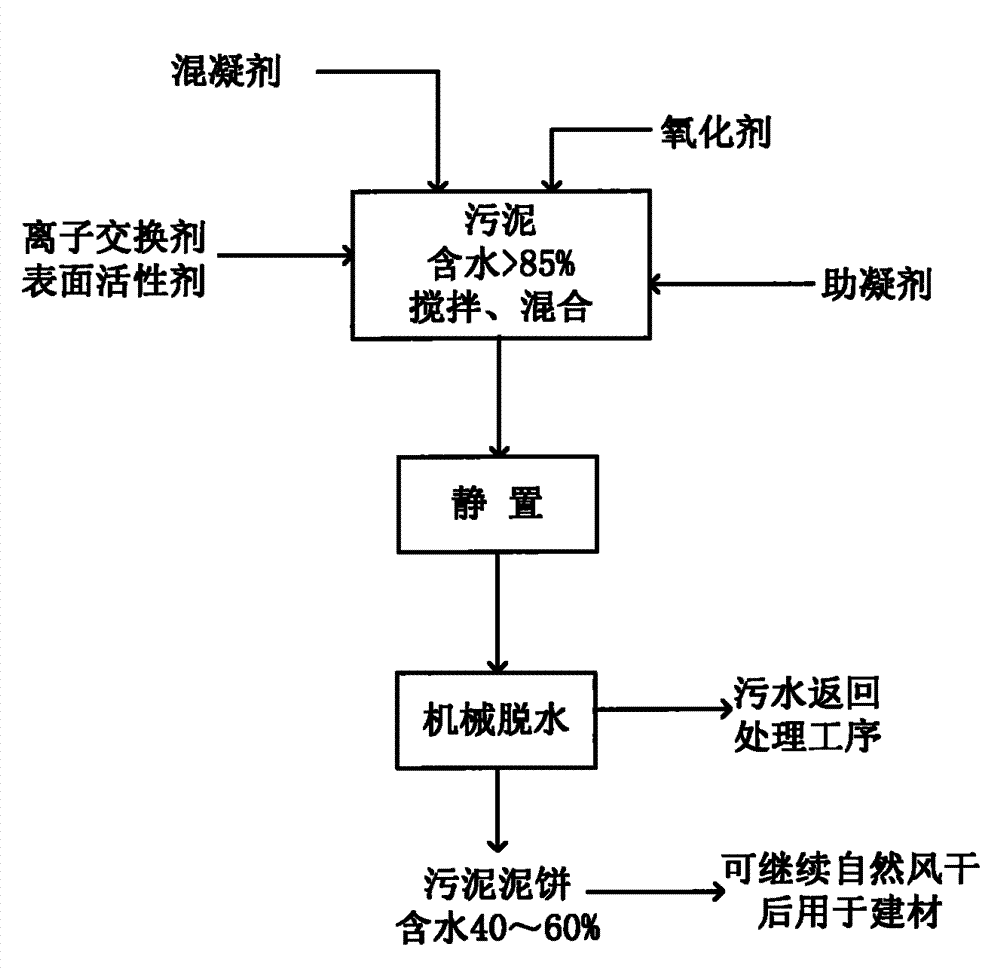

Image

Examples

Embodiment 1

[0029] 1) Take concentrated sludge with a moisture content of 98.6% from an urban sewage treatment plant, and add a conditioner composed of the following mass percentages: 13% asbestos tailings, 30% carbide slag, 8% serpentine, 9% dolomite, kaolin 5%, diatomaceous earth 5%, bentonite 5%, clay 5%, sodium humate 5%, ferric chloride 4%, aluminum chloride 3%, pyrolusite 4%, sodium hypochlorite 2.5%, lauryl Sodium benzenesulfonate 1.0%, polysorbate 0.5%, the dosage of conditioner is 1.2% of the sludge amount;

[0030] 2) How to use: first add ferric chloride and aluminum trichloride to the sludge, stir rapidly for about 1 minute, then add pyrolusite and sodium hypochlorite, and continue stirring rapidly for 3 minutes; then add sodium humate and dodecylbenzenesulfonate Sodium acid and polysorbate, continue to stir rapidly for about 1min, then add bentonite and clay, continue to stir rapidly for 2min; again, add asbestos tailings, carbide slag, serpentine, dolomite, kaolin and diatom...

Embodiment 2

[0033] 1) Take concentrated sludge with a water content of 97.5% in ammonia nitrogen wastewater from a coking plant, and add a conditioning agent composed of the following mass percentages: 10% asbestos tailings, 35% carbide slag, 6% serpentine, 9% dolomite, and kaolin 3%, diatomaceous earth 7%, bentonite 6%, clay 4%, potassium humate 5%, polyaluminum sulfate 5%, pyrolusite 5%, potassium hypochlorite 3%, cetyl pyridinium bromide 1%, alkanes Alcohol amide 1%, the dosage of conditioning agent is 2.1% of the sludge amount;

[0034] 2) How to use: first add iron salt and / or aluminum salt to the sludge, stir rapidly for about 1.5min, then add pyrolusite and potassium hypochlorite, continue stirring rapidly for 3.5min; then add potassium humate and cetyl bromide Add pyridine and alkyl alcohol amide, continue to stir rapidly for about 1.5min, then add bentonite and clay, continue to stir rapidly for 2.5min; again, add asbestos tailings, carbide slag, serpentine, dolomite, kaolin and ...

Embodiment 3

[0037]1) Take the concentrated sludge with a water content of 93.8% in organic waste water from textile mills, add the following conditioning agent in mass percent: 7% asbestos tailings, 33% carbide slag, 8% serpentine, 7% dolomite, kaolin 9%, diatomite 8%, bentonite 5%, clay 3%, sodium humate 3%, iron sulfate 5%, polyaluminum sulfate 2%, pyrolusite 4%, sodium hypochlorite 3.5%, dodecylbenzenesulfonic acid Sodium 1%, alkanolamide 1.5%, conditioner dosage is 2.5% of sludge volume;

[0038] 2) How to use: first add ferric sulfate and polyaluminum sulfate to the sludge, stir rapidly for about 2 minutes, then add pyrolusite and sodium hypochlorite, and continue stirring rapidly for 3 minutes; then add sodium humate, sodium dodecylbenzenesulfonate and alkanes Alcohol amide, continue to stir rapidly for about 1.5 minutes, then add bentonite and clay, continue to stir rapidly for 3 minutes; again, add asbestos tailings, carbide slag, serpentine, dolomite, kaolin and diatomite, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com