Organic reversible thermochromic microcapsule with long service life and large color difference and preparation method thereof

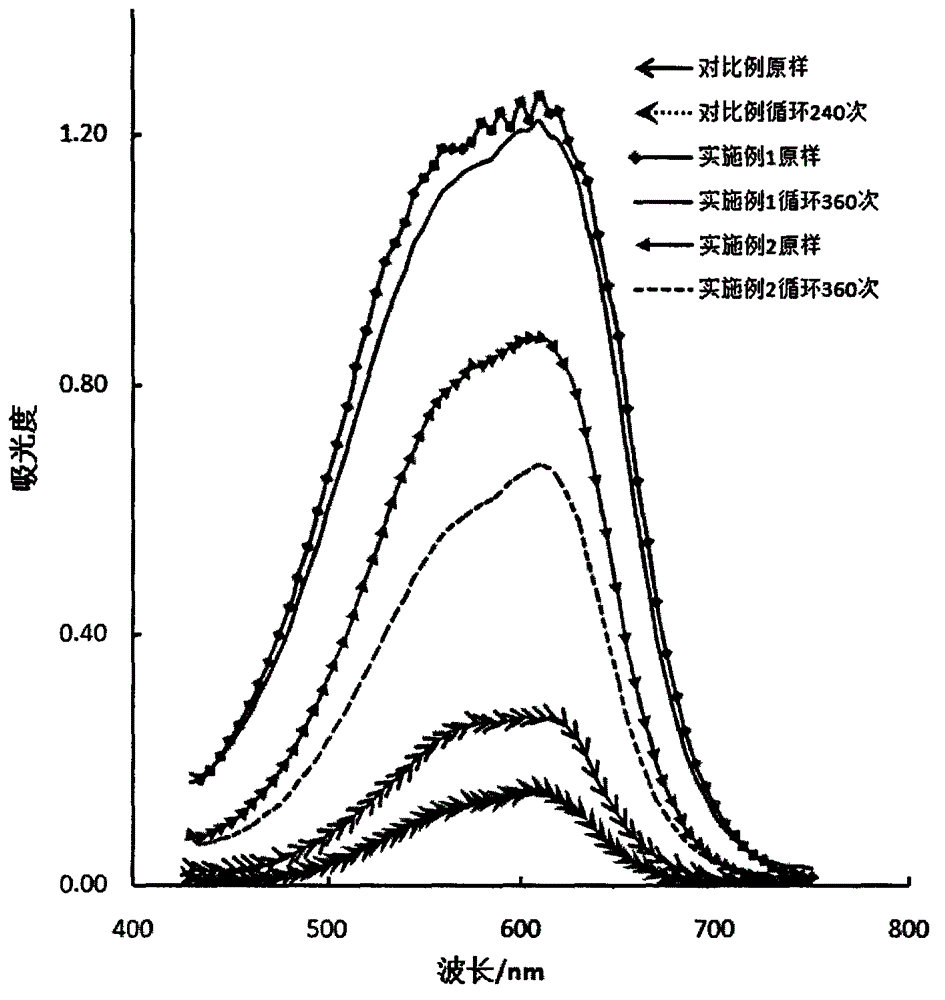

A thermochromic and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, color-changing fluorescent materials, etc., can solve the problems of small color difference, poor light transmission, short service life, etc., and achieve safe use, long life, and color difference. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The method for preparing organic reversible thermochromic microcapsules with long color difference and large color difference includes the following steps:

[0049] a) adding an oil-soluble initiator to the monomer A or the mixture of monomer A and monomer C for prepolymerization,

[0050] b) Add organic reversible thermochromic compound after prepolymerization,

[0051] c) adding monomer B to disperse it into an oil-in-water emulsion in an aqueous solution containing a dispersant,

[0052] d) performing free radical polymerization, filtering, washing and drying to obtain organic reversible thermochromic microcapsules.

[0053] The initiator is preferably azobisisobutyronitrile, the amount of the initiator is preferably 0.5-2% by weight of the monomer A, the prepolymerization temperature is between 60°C and 70°C, and the prepolymerization time is 30 minutes.

[0054] Acrylate and / or methacrylate molecules contain carbon-carbon double bonds, and the groups connected to...

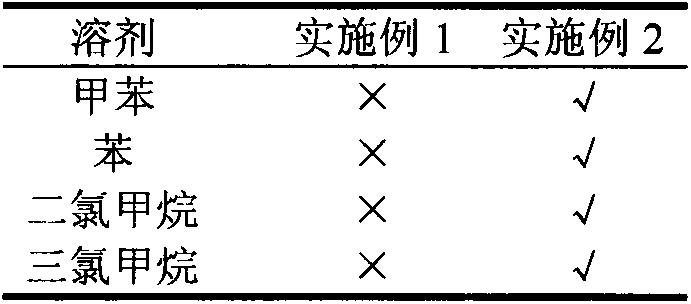

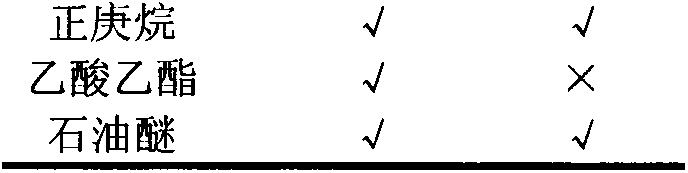

Embodiment 1

[0059] Example 1. Weigh 10.0 grams of refined methyl methacrylate (MMA) with an electronic balance in a three-necked flask, add 0.10 grams of initiator azobisisobutyronitrile (AIBN), and prepolymerize in a water bath at 65°C 30min, add 10.0 grams of organic reversible thermochromic compound, add 1.00 g of divinylbenzene (DVB), the proportion of organic reversible thermochromic compound is 3,3-bis(4-dimethylaminophenyl)- 6-dimethylaminophthalide: 4,4'-dihydroxydiphenyl sulfone: the proportioning ratio of 1-hexadecanol is 1:3:150, and the mixture is added with 200 grams of weight percentage and the concentration is 0.3% polyvinyl alcohol ( In the PVA) aqueous solution, use a high-shear emulsifier to shear and emulsify for 3 minutes, then raise the temperature to 75° C., continue the reaction for 3 hours, and then raise the temperature to 85° C. for 1 hour. The product is washed, filtered, and dried to obtain a microcapsule product powder.

Embodiment 2

[0060]Example 2, take 10.0 grams of refined methyl methacrylate (MMA) and 0.20 grams of methacrylic acid (MAA) with an electronic balance in a three-necked flask, add 0.10 grams of initiator azobisisobutyronitrile (AIBN) , pre-polymerized in a water bath at 65°C for 30 minutes, added 10.0 grams of thermochromic compound, added 1.50 grams of divinylbenzene, the organic reversible thermochromic compound ratio is 3,3-bis(4-dimethylamine Phenyl)-6-dimethylaminophthalide: 4,4'-dihydroxydiphenyl sulfone: the ratio of 1-hexadecanol is 1:3:150, the mixture is added to 200 grams by weight and the concentration is 0.3% Polyvinyl alcohol (PVA) aqueous solution was sheared and emulsified for 3 minutes using a high-shear emulsifier, then the temperature was raised to 75° C., the reaction was continued for 3 hours, and the temperature was raised to 85° C. for 1 hour. The product is washed, filtered, and dried to obtain a microcapsule product powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com