High-strength and good-abrasion-resistance zirconium carbide ceramic material and preparing method thereof

A technology of ceramic materials and zirconium carbide, which is applied in the field of ceramic materials, can solve the problems of low mechanical strength and achieve the effects of improving wear resistance, high mechanical strength and chemical stability, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

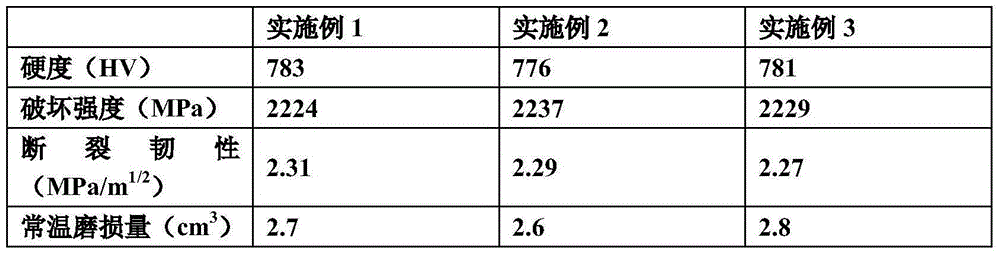

Examples

Embodiment 1

[0016] A zirconium carbide ceramic material with high strength and good wear resistance, made of the following weight (kg) raw materials: kaolin 16, zirconium carbide 80, tungsten powder 2, black diamond powder 7, stainless steel powder 3, fly ash 6, ceramics Waste 8, polysilicate ferric sulfate 1, water glass 2, white oil 6, ferrosilicon nitride powder 3, red mud 1, molybdenum disilicide 1, polyvinyl alcohol 2, potassium nitrite 0.5, additive 5, water amount The auxiliary agent is made of the following weight (kg) raw materials: aluminum oxide 20, magnesium aluminum spinel powder 6, yttrium carbonate 1, silicon nitride 2, earthy graphite powder 2, diamond powder 0.5, bone powder 2, poly Sodium acrylate 0.5, polyethylene glycol 1, glycerin 2, water in proper amount; the preparation method is: mix aluminum oxide, magnesium aluminum spinel powder, yttrium carbonate, silicon nitride, earthy graphite powder, diamond powder, and bone powder into the mixture In the feeder, add sodiu...

Embodiment 2

[0023] A zirconium carbide ceramic material with high strength and good wear resistance, made of the following weight (kg) raw materials: kaolin 17, zirconium carbide 90, tungsten powder 2, black diamond powder 8, stainless steel powder 4, fly ash 7, ceramics Waste 10, polysilicate iron sulfate 2, water glass 3, white oil 7, ferrosilicon nitride powder 4, red mud 2, molybdenum disilicide 1, polyvinyl alcohol 3, potassium nitrite 0.6, additive 6, water amount ; The auxiliary agent is made of the following weight (kg) raw materials: aluminum oxide 25, magnesium aluminum spinel powder 7, yttrium carbonate 1, silicon nitride 2, earthy graphite powder 3, diamond powder 0.8, bone meal 3, poly Sodium acrylate 0.7, polyethylene glycol 2, glycerin 3, water in proper amount; the preparation method is: mix aluminum oxide, magnesium aluminum spinel powder, yttrium carbonate, silicon nitride, earthy graphite powder, diamond powder, and bone powder into the mixture In the feeder, add sodium...

Embodiment 3

[0030] A zirconium carbide ceramic material with high strength and good wear resistance, made of the following weight (kg) raw materials: kaolin 18, zirconium carbide 95, tungsten powder 3, black diamond powder 9, stainless steel powder 4, fly ash 8, ceramics Waste 12, polysilicate iron sulfate 3, water glass 3, white oil 8, ferrosilicon nitride powder 5, red mud 3, molybdenum disilicide 2, polyvinyl alcohol 4, potassium nitrite 0.8, additive 7, water amount ;

[0031] The auxiliary agent is made of the following weight (kg) raw materials: alumina 30, magnesium aluminum spinel powder 8, yttrium carbonate 2, silicon nitride 3, earthy graphite powder 4, diamond powder 1, bone powder 3, polyacrylic acid Sodium 0.8, polyethylene glycol 3, glycerin 4, water in proper amount; the preparation method is: mix alumina, magnesium aluminum spinel powder, yttrium carbonate, silicon nitride, earthy graphite powder, diamond powder, and bone powder to the mixture In the machine, add sodium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com