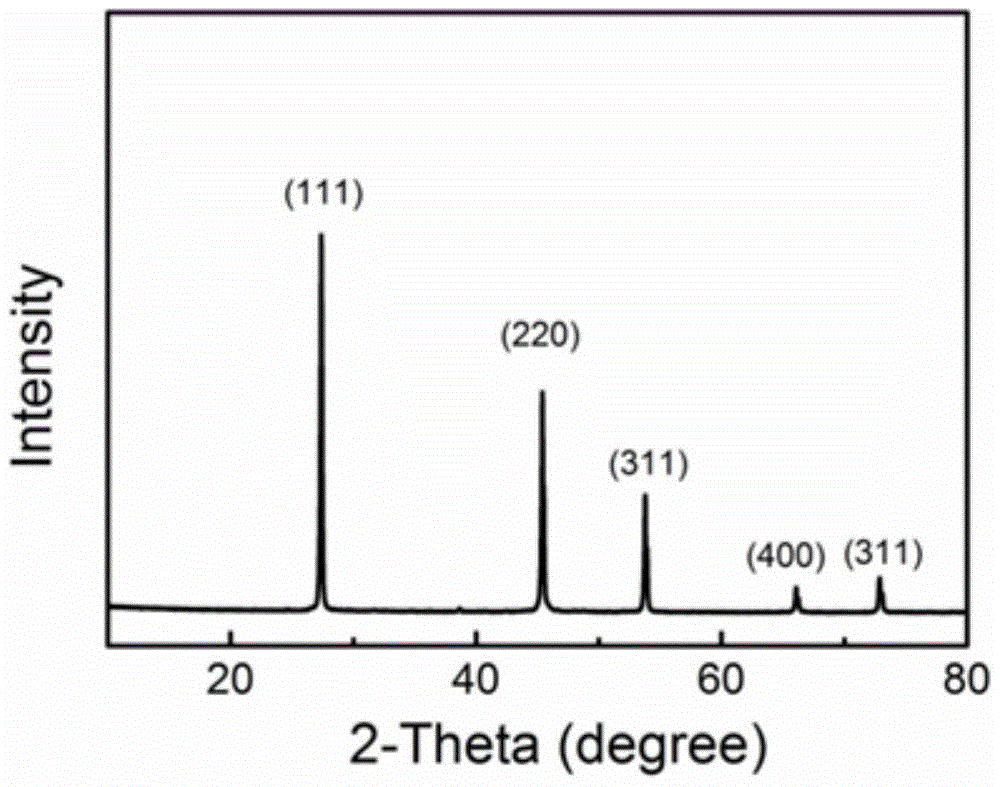

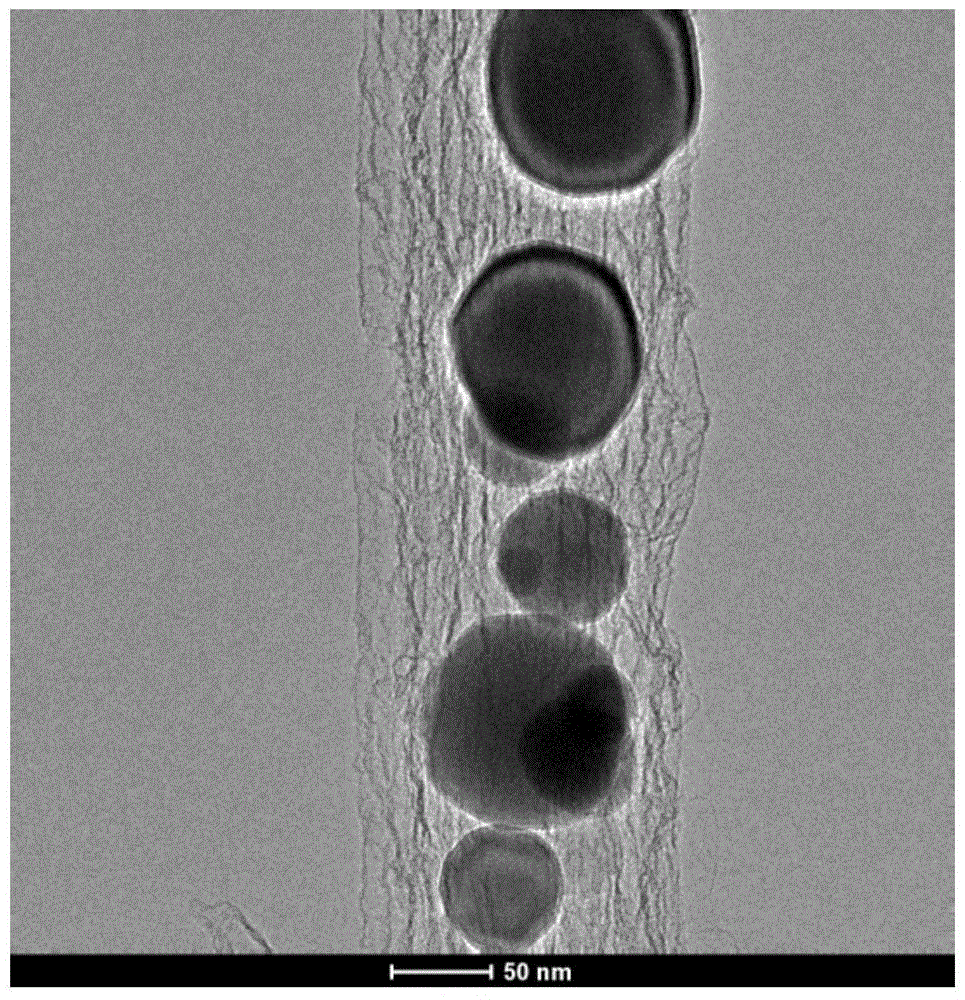

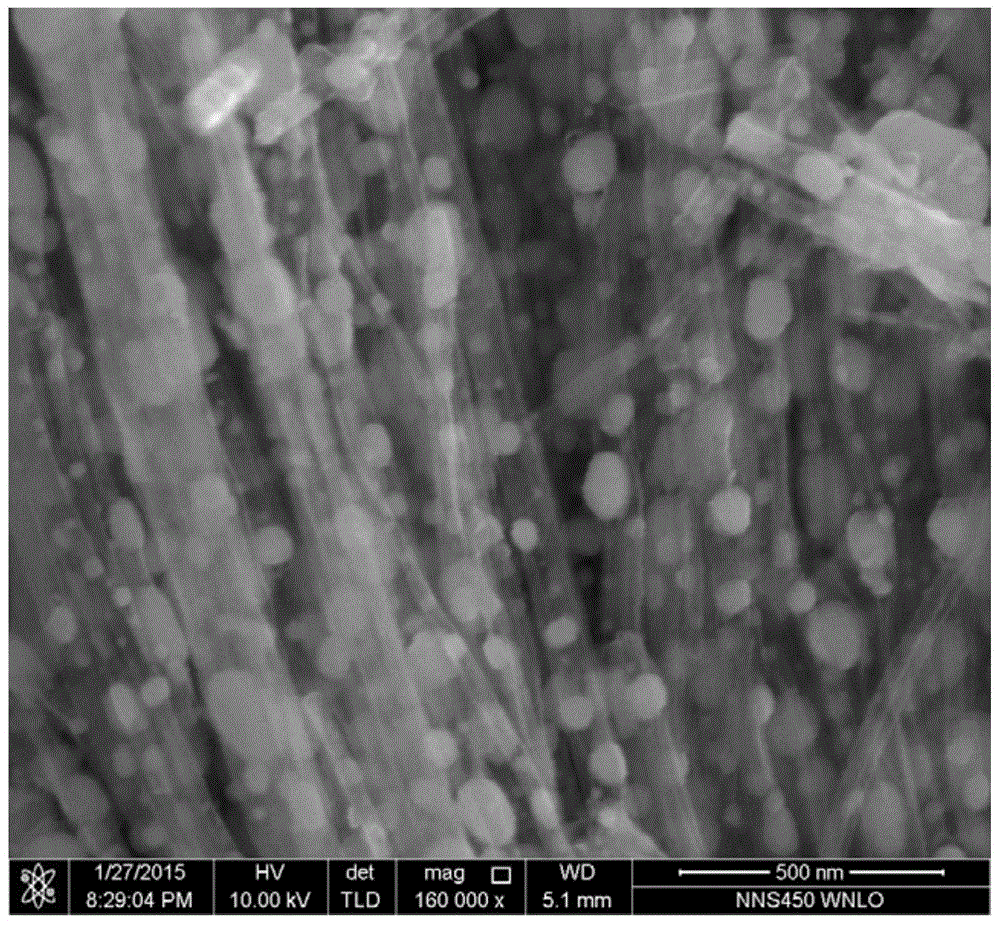

A kind of preparation method and application of germanium-carbon-nitrogen nanocomposite material

A technology of nanocomposite materials and carbon-nitrogen nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of easy dissolution of germanium oxide, achieve electrochemical interface stability, and reduce production costs. Low, improve the effect of energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In order to achieve the above object, according to one aspect of the present invention, a kind of preparation method of germanium-carbon nitrogen nanocomposite material is provided, it is characterized in that, comprises the following steps:

[0030] (1) Preparation of germanium oxide nanowires

[0031] The following methods are often used to prepare germanium oxide nanowire precursors:

[0032] a. Carbothermal evaporation method: Mix germanium dioxide powder and activated carbon at a mass ratio of 1:2 to 2:1 and grind them thoroughly, then transfer them to a corundum boat with a ceramic cover, and place them in an oxygen flow at 700°C to 950°C Keep warm at ℃ for 2.5h-4h, and collect the germanium oxide nanowires on the ceramic cover.

[0033] b. Co-thermal evaporation method: mix high-purity germanium powder and 6% to 12% iron powder with a quality of germanium powder, hot press at 120°C to 180°C, and press at 750°C under a pressure of 150 to 200 Torr Incubate at ~95...

Embodiment 1

[0046] (1) Grind 2g of germanium oxide and 0.5g of activated carbon with an agate mortar for 5min until uniformly mixed, transfer the mixture to a 100ml hydrothermal kettle, add 12ml of water and 8ml of ethylenediamine to the hydrothermal kettle, and heat Seal the kettle, put it in an oven at 200°C for 96 hours, and wait for the hydrothermal kettle to cool down to room temperature, take out the white suspended matter in the above solution, and wash it three times with distilled water and ethanol. The product was calcined in air at 500°C for 2h in a muffle furnace.

[0047] (2) Take 200 mg of the calcined product and uniformly disperse it in 20 ml of anhydrous methyl acetate, add 20 mg of polyvinyl acetate and 100 mg of anhydrous ferric trichloride, and stir to form a uniform dispersion. Then 20 microliters of pyrrole was added dropwise to the dispersion, and stirred at room temperature for 24 hours. The obtained product was filtered and washed three times, and dried at 50°C f...

Embodiment 2

[0053] (1) Grind 1.5g of germanium dioxide powder and 1.5g of activated carbon fully, then transfer them to a corundum boat with a ceramic cover, keep it warm at 840°C for 3.5h in an oxygen flow of 20 sccm, and collect the germanium oxide precursor on the ceramic cover .

[0054] (2) Take 300 mg of the precursor and disperse it evenly in 20 ml of anhydrous methyl acetate, add 15 mg of polyvinyl acetate and 90 mg of anhydrous ferric chloride, and stir to form a uniform dispersion. Then 15 mg of pyrrole was added dropwise to the dispersion, and stirred at room temperature for 30 h. The obtained product was filtered and washed three times, and dried at 50°C for 5 hours.

[0055] (3) The obtained product was calcined at 650° C. for 4 h in an argon-hydrogen mixed gas containing 4% hydrogen, and the heating rate was 1° C. / min. The germanium-carbon nitrogen nanocomposite electrode material was obtained, and the electrochemical test part was the same as in Example 1, and the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com