Rechargeable quinone-manganese oxide aqueous battery

A lithium manganese oxide battery technology, applied in battery electrodes, secondary battery manufacturing, circuits, etc., can solve the problems of low specific capacity and short cycle life, and achieve high specific capacity, long cycle life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

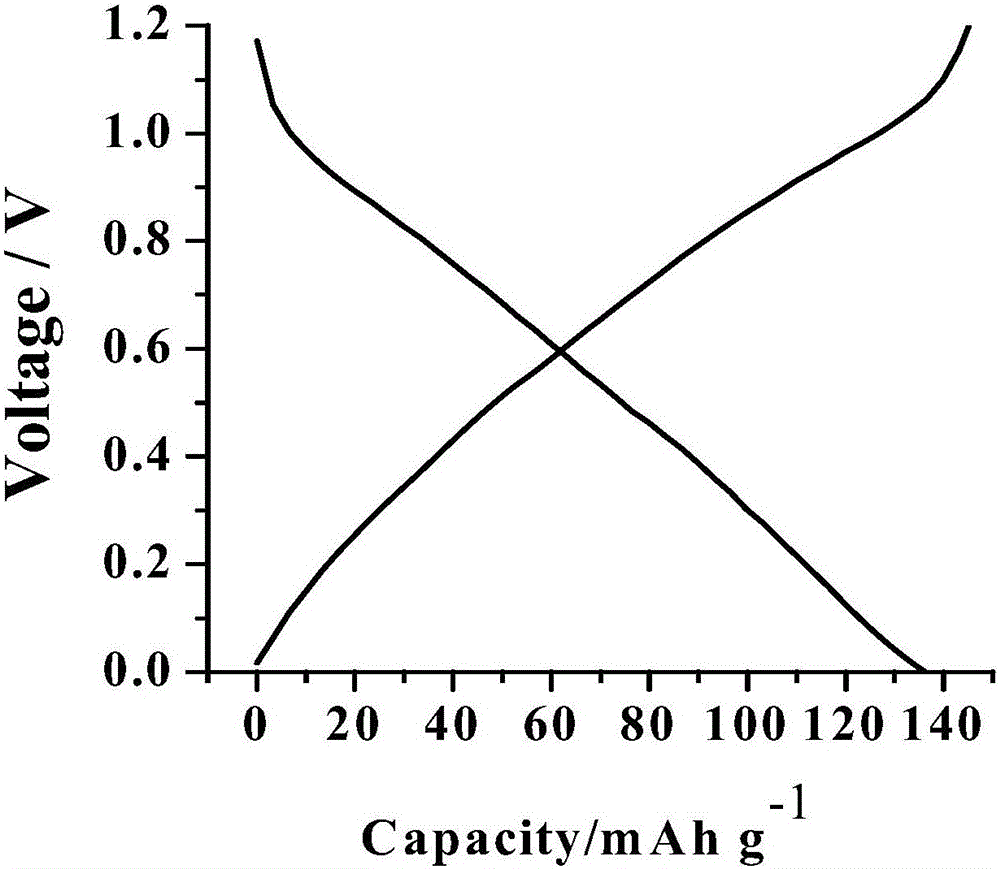

[0024] Using 1,5-diaminoanthraquinone as a monomer, oxidatively polymerizes to obtain poly-1,5-diaminoanthraquinone, and obtains a negative electrode active material. Take LiMn 2 o 4 As the starting material, according to the target product Li 3 mn 2 o 4 Calculate the lithium source of the stoichiometric ratio, add lithium carbonate, put it into a stainless steel ball mill tank for ball milling and mixing, add 10% polyvinyl alcohol to the powder raw material after ball milling to granulate, put it into a ceramic boat, and place it in a muffle In the furnace, when the air atmosphere was raised to 700°C at a heating rate of 2°C / min, the temperature was kept constant for 12 hours, and then naturally cooled to room temperature. After the product was crushed and sieved, the lithium-rich manganese oxide lithium positive electrode active material was obtained. The lithium-rich manganese oxide lithium material and anthraquinone polymer were mixed with acetylene black and polytetra...

Embodiment 2

[0026] Dissolve chloranil and 10wt% carbon nanotubes in NMP solvent at 160 0 C and Na 2 Polythiobenzoquinone and carbon nanotube composites were prepared by S reactive vulcanization polymerization. Mix this compound with acetylene black and PTFE binder according to the mass ratio of 80:15:5 to make a slurry, roll it into shape, press it on the stainless steel mesh collector with a pressure of 20Mpa, and dry it in the air at 393K for 6 hours Made of negative electrode sheet. With manganese acetate as the starting material, dissolved in water, according to the target product Li 4 mn 2 o 4 Calculate the lithium source of the stoichiometric ratio, add lithium acetate and dissolve to form an aqueous solution, stir and heat to remove water, add 10% polyvinyl alcohol to the solid powder after water removal, mix and granulate, put it into a ceramic boat, and place it in a muffle In the furnace, when the air atmosphere was raised to 700°C at a heating rate of 2°C / min, the temperat...

Embodiment 3

[0028] Dissolve 2,5 dihydroxybenzoquinone in acetic acid solvent at 80 0 Polymerized with formaldehyde under C to obtain poly-2,5 dihydroxybenzoquinone. This quinone polymer is mixed with acetylene black and PTFE binder according to the mass ratio of 55:40:5 to make a slurry, rolled and formed, pressed onto the stainless steel mesh collector with a pressure of 20Mpa, and dried at 393K in the air for 6 hours to make the negative electrode sheet. MnO 2 As the starting material, according to the target product Li 2 mn 2 o 4 Calculate the lithium source of the stoichiometric ratio, add lithium carbonate and mix evenly by ball milling, add 10% polyvinyl alcohol to the solid powder mixture, mix and granulate, put it in a ceramic boat, place it in a muffle furnace, and heat it in an air atmosphere at 5°C When the heating rate is increased to 500°C / min, the temperature is kept constant for 5 hours, and then the temperature is raised to 750°C at a rate of 2°C / min. . Mix this lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com