Preparation method of small-layer-number MoSe2 nanosheet/nitrogen and phosphorus co-doped graphene composite nanomaterial

A graphene composite, nanomaterial technology, applied in the directions of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not considering effective regulation and the low degree of phosphorus doping in phosphorus-doped graphene , uneven doping and other problems, to achieve the effect of easy to expand industrial application, convenient to expand industrial application, high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

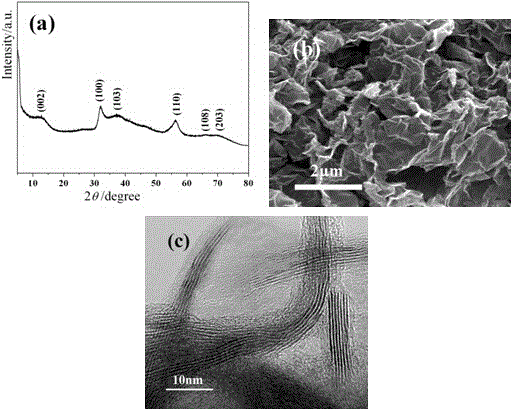

Embodiment 1

[0030] A few-layer MoSe 2 The nanosheet / nitrogen and phosphorus co-doped graphene composite nanomaterial comprises the following steps:

[0031] S1. Ultrasonic disperse 3.0mmol graphene oxide in 45mL deionized water, then add 1.5mmol tetrabutylphosphine bromide and stir thoroughly for 12 hours, then add 1.5mmol sodium molybdate and 15mL hydrazine dissolved with 3mmol selenium powder Solution, and keep stirring to completely dissolve the sodium molybdate.

[0032] S2. Transfer the mixed solution obtained in S1 (total volume is 60mL) to a 100mL hydrothermal reaction kettle, put the reaction kettle in a constant temperature oven, and allow it to cool naturally to room temperature after hydrothermal reaction at 240°C for 24 hours. The solid product was collected by centrifugation, washed thoroughly with deionized water, and dried in vacuum at 80°C; the solid product obtained above was heat-treated at 800°C for 2 hours in a nitrogen atmosphere to prepare MoSe with few layers 2 Na...

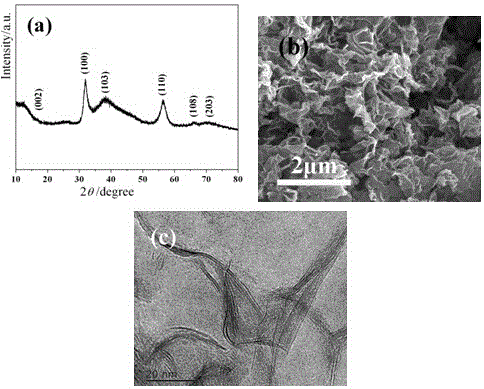

Embodiment 2

[0037] A few-layer MoSe 2 The nanosheet / nitrogen and phosphorus co-doped graphene composite nanomaterial comprises the following steps:

[0038] S1. Ultrasonic disperse 3.0mmol graphene oxide in 45mL deionized water, then add 4.5mmol tetrabutylphosphine bromide and stir thoroughly for 12 hours, then add 1.5mmol sodium molybdate and 15mL hydrazine dissolved with 3mmol selenium powder Solution, and keep stirring to completely dissolve the sodium molybdate.

[0039] S2. Transfer the mixed solution obtained in S1 (total volume is 60mL) to a 100mL hydrothermal reaction kettle, put the reaction kettle in a constant temperature oven, and allow it to cool naturally to room temperature after hydrothermal reaction at 250°C for 24 hours. The solid product was collected by centrifugation, washed thoroughly with deionized water, and dried in vacuum at 80°C; the solid product obtained above was heat-treated at 800°C for 2 hours in a nitrogen atmosphere to prepare MoSe with few layers 2 Na...

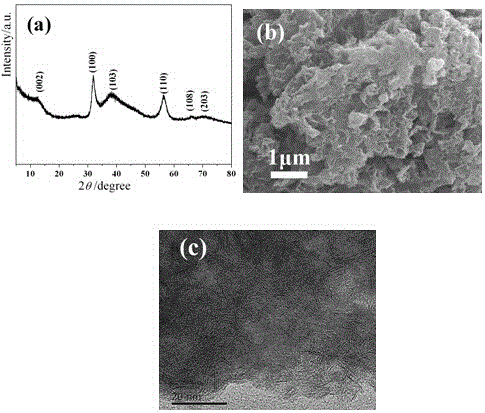

Embodiment 3

[0044] A few-layer MoSe 2 The nanosheet / nitrogen and phosphorus co-doped graphene composite nanomaterial comprises the following steps:

[0045] S1. Ultrasonic disperse 3.5mmol graphene oxide in 45mL deionized water, then add 6mmol tetrabutylphosphine bromide and fully stir for 12 hours, then add 2mmol sodium molybdate and 15mL hydrazine solution in which 4mmol selenium powder is dissolved, And keep stirring to completely dissolve the sodium molybdate.

[0046] S2. Transfer the mixed solution obtained in S1 (total volume is 60mL) to a 100mL hydrothermal reaction kettle, put the reaction kettle in a constant temperature oven, and allow it to cool naturally to room temperature after hydrothermal reaction at 260°C for 24 hours. The solid product was collected by centrifugation, washed thoroughly with deionized water, and dried in vacuum at 80°C; the solid product obtained above was heat-treated at 700°C for 2 hours in a nitrogen atmosphere to prepare MoSe with few layers 2 Nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com