A kind of layered composite metal hydroxide and its multifunctional masterbatch preparation method

A composite metal and hydroxide technology, applied in the field of chemical materials, can solve the problems of high raw material consumption, raw material cost, freight and labor costs, affecting the health of workers, and excessive dust in the workplace, achieving less raw material consumption and product quality. The effect of stability and reduced work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

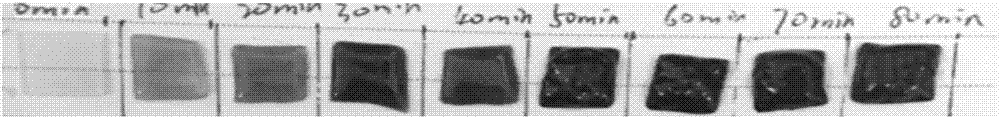

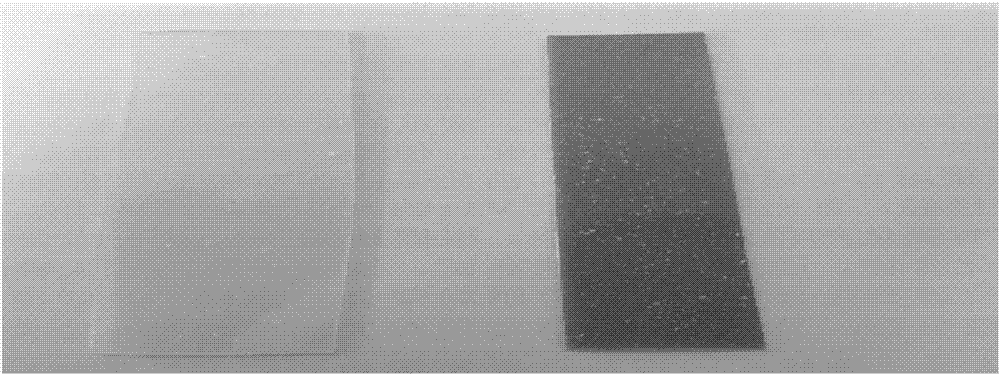

[0037] This embodiment relates to a preparation method of nano-layered composite metal hydroxide:

[0038] The first step is to prepare magnesium ion aqueous solution. Dissolve 74.55Kg of industrial magnesium sulfate into 400Kg of deionized water, mix and prepare to obtain a magnesium ion aqueous solution with a concentration of 0.75mol / L;

[0039] The second step is to prepare an alkaline solution of aluminum. 8.54Kg sodium metaaluminate, 8.33Kg sodium hydroxide and 21.24Kg Na 2 CO 3 Dissolved in 400Kg deionized water, mixed and prepared to obtain an alkaline solution of aluminum with a concentration of 0.25mol / L;

[0040] The third step is to add the aluminum alkali solution and the magnesium ion aqueous solution in equal proportions to the high-shear dispersing emulsifier under the premise of volumetric metering, and mix quickly and uniformly.

[0041] In the fourth step, the suspension formed by the high-shear dispersing and emulsifying machine is passed into the close...

Embodiment 2

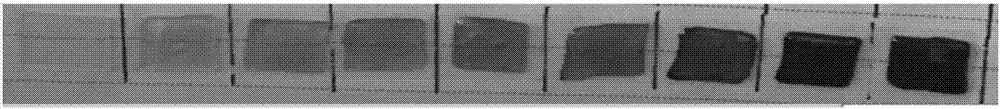

[0046] The first step is to prepare a mixed aqueous solution of magnesium and zinc ions. Dissolve 77Kg of industrial zinc nitrate hexahydrate and 30Kg of industrial zinc nitrate hexahydrate into 500Kg of deionized water, mix and prepare to obtain a mixed aqueous solution of magnesium and zinc ions;

[0047] The second step is to prepare an alkaline solution of aluminum. Dissolve 17.08Kg of sodium metaaluminate, 12.5Kg of sodium hydroxide and 42.48Kg of sodium carbonate into 500Kg of deionized water, mix and prepare to obtain an alkaline solution of aluminum with a concentration of 0.4mol / L;

[0048] In the third step, the above-mentioned aluminum alkali solution and the mixed aqueous solution of magnesium and zinc ions are added to the colloid mill in equal proportions under the premise of volumetric measurement, and mixed rapidly and uniformly.

[0049] The fourth step is to pass the suspension formed by the colloid mill into the reaction kettle. The temperature was raised ...

Embodiment 3

[0054] The mass percentages of each component of the masterbatch are: 43% polyethylene, 40% nano-layered composite metal hydroxide obtained in Example 1, 5% maleic anhydride grafted polyethylene, 4% white oil, silicone 1%, EBS 2%, stearic acid 2%, calcium stearate 1%, 3-propylene oxide 2%.

[0055] Add the nano-layered composite metal hydroxide, 3-propylene oxide, and dispersant prepared in Example 1 into a high-speed mixer and mix for 5 minutes to obtain a pre-dispersion. The maleic anhydride grafted polyethylene, polyethylene and pre-dispersion were respectively added to the internal mixer for mixing, and the materials obtained by mixing at 160°C for 15 minutes were cooled to 30°C and discharged. The mixed materials are added to twin-screws for melt blending, extruded and granulated to obtain multifunctional masterbatches. The twin-screw processing temperatures are 145, 155, 160, 170, 175, 165, 170, and 180°C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com