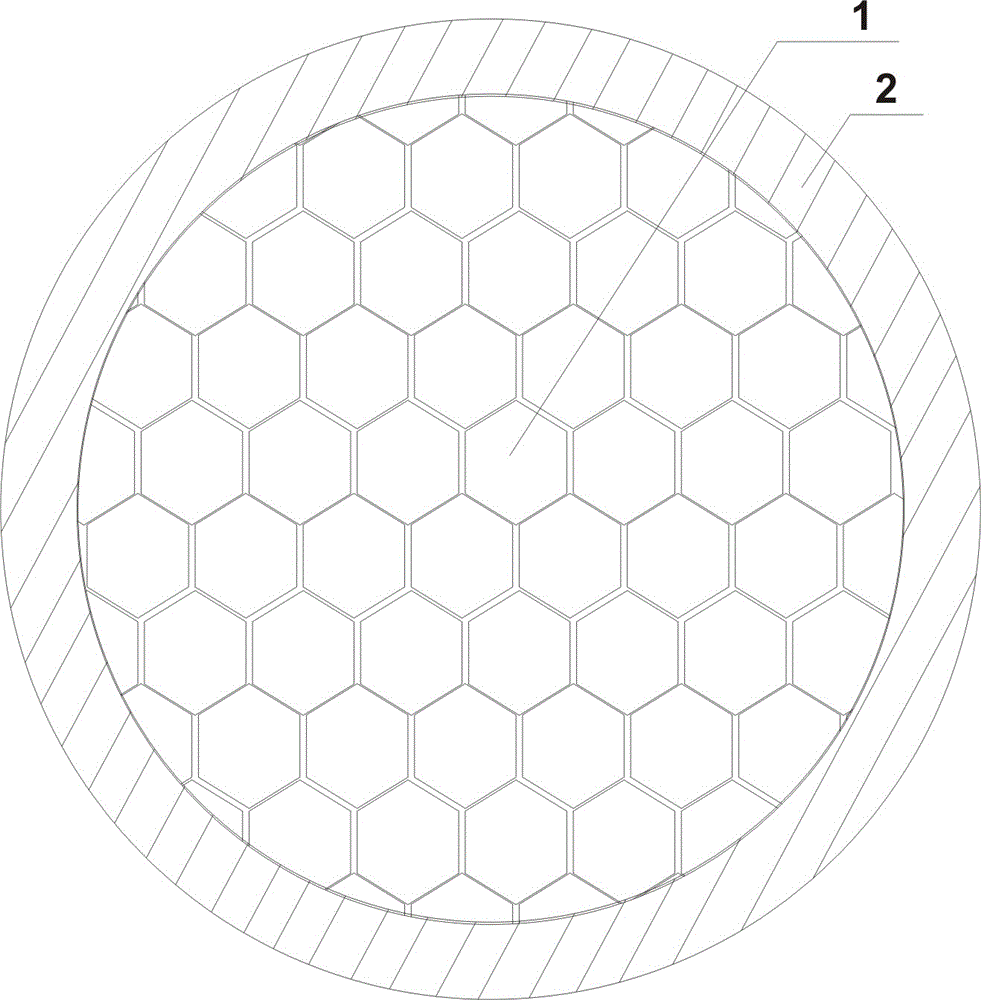

Biological organic-inorganic loss-controlled fertilizer with core-shell structure

A core-shell structure, biological technology, applied in the direction of organic fertilizers, fertilizers made of biological waste, nitrogen fertilizers, etc., can solve the problems of lack of resource utilization, poor plant root development, environmental pollution, etc., to improve stress resistance. performance and product quality, improving soil physical and chemical properties, and improving soil ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Mix 400kg of poultry manure (water content about 65%), 300kg of straw powder, 10kg of urea, 10kg of ammonium sulfate, and 20kg of distiller's grains, add 0.1kg of enzyme agent, ferment for about two weeks, discharge, dry, add 3.7 kg borax, 7.0kg zinc sulfate heptahydrate, 3.1kg manganese sulfate monohydrate, 15kg ammonium fulvic acid, 60kg bentonite, 30kg polyaspartic acid, crushed into 60-80 mesh powder, and 430kg inorganic fertilizer granules (20-12 -18) After mixing evenly, spray an appropriate amount of binder to granulate, bake until the moisture content is below 15%, spray an aqueous solution of biological beneficial bacteria, dry at low temperature, sieve and pack, and obtain the finished core-shell structure bio-organic-inorganic loss-controlling fertilizer . The main technical indicators are: organic matter ≥ 40%, humic acid ≥ 15%, trace elements ≥ 0.3%, total nitrogen ≥ 10%, phosphorus pentoxide ≥ 5%, potassium oxide ≥ 8%, effective viable bacteria ...

Embodiment 2

[0026] Example 2: Mix 200kg of poultry manure (water content about 65%), 150kg of straw powder, 10kg of urea, and 40kg of distiller's grains evenly, add 0.1kg of enzyme agent, ferment for about two weeks, discharge, dry, add 3.7kg of borax, 7.0 kg zinc sulfate heptahydrate, 3.1kg manganese sulfate monohydrate, 10kg ammonium fulvic acid, 50kg bentonite, 60kg polyaspartic acid, crushed into 60-80 mesh powder, mixed with 600kg inorganic fertilizer granules (30-10-10) After uniformity, spray an appropriate amount of binder to granulate, bake until the moisture content is below 15%, spray an aqueous solution of biological beneficial bacteria, dry at low temperature, sieve and pack, and obtain the finished bio-organic-inorganic loss-controlling fertilizer with a core-shell structure. The main technical indicators are: organic matter ≥ 25%, humic acid ≥ 12%, trace elements ≥ 0.3%, total nitrogen ≥ 20%, phosphorus pentoxide ≥ 6%, potassium oxide ≥ 6%, the number of effective viable bac...

Embodiment 3

[0027] Example 3: Mix 100kg of poultry manure (water content about 65%), 80kg of straw powder, and 20kg of urea evenly, add 0.05kg of enzyme agent, ferment for about two weeks, discharge, dry, add 3.0kg of borax, 7.0kg of heptahydrate Zinc sulfate, 3.0kg manganese sulfate monohydrate, 3.0kg ammonium molybdate, 30kg ammonium fulvic acid, 50kg bentonite, 20kg polyaspartic acid, crushed into 60-80 mesh powder, mixed with 780kg inorganic fertilizer granules (30-12- 10) After mixing evenly, spray an appropriate amount of binder to granulate, bake until the water content is below 15%, spray an aqueous solution of biological beneficial bacteria, dry at low temperature, sieve and pack, and obtain the finished core-shell structure bio-organic-inorganic loss-controlling fertilizer. The main technical indicators are: organic matter ≥ 10%, humic acid ≥ 12%, trace elements ≥ 0.35%, total nitrogen ≥ 25%, phosphorus pentoxide ≥ 10%, potassium oxide ≥ 7%, effective viable count ≥ 200 million / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com