Large tank liquid making process of red yeast yellow rice wine

A red yeast rice wine and process technology, applied in the preparation of alcoholic beverages and other directions, can solve the problems of large proportion of glass particles, poor product taste, and difficult to decompose, and meet the requirements of ensuring hygiene, breaking through the poor taste, and eliminating the taste of fresh water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of auxiliary material

[0020] (1) Configuration of activator: Weigh 300g-350g of magnesium chloride, 200g-300g of potassium chloride, 100g-200g of iron pyrophosphate and 100g-150g of zinc sulfate, mix and grind them for later use.

[0021] (2) Preparation of brown rice bud powder: first, refer to the literature to prepare brown rice buds; then put the brown rice buds into a drum-type frying furnace and keep them warm for 30 minutes at 85°C, take them out and let them cool; The distance between the rollers is 0.5mm, and the rotation speed is 250rpm; put the crushed brown rice buds in an extraction kettle, add 5 times the mass of water, and extract by ultrasonic for 12 minutes; filter the extract at room temperature with a 500-mesh filter cloth and a plate-and-frame filter , filtered, concentrated in vacuum, and then dried with a spray dryer at an inlet air temperature of 160°C and an exhaust air temperature of 80°C to obtain brown rice bud ...

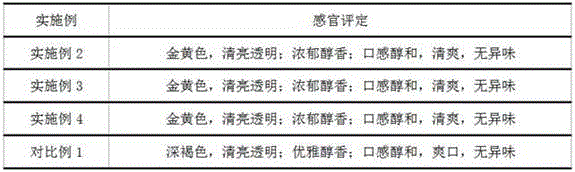

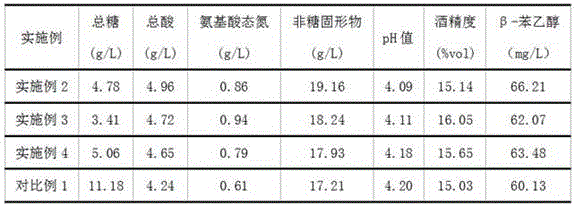

Embodiment 2

[0024] Weigh 2800kg of 40-mesh glutinous rice flour, 800kg of japonica rice flour and 400kg of sorghum flour respectively, and mix the powder materials with 10t of water through a water-powder mixer. Use a high-pressure pump to quickly inject the adjusted slurry into the high-pressure injector. The pressure of the slurry and the superheated steam pressure are 0.3MPa and 0.8MPa respectively, and the density of the superheated steam is 4.2kg / m 3 , the spraying temperature is controlled at 160°C, keep warm in the serpentine tube for 15min, adjust the pH to 5.6 after vacuum flash cooling to 95°C, add 800g of high temperature resistant α-amylase and 160g of activator, mix well and keep warm for 25min, then liquefy The reaction of liquid iodine is light red, with a DE value of 10%. Then the enzyme is sprayed at a temperature of 135°C, and then enters a plate heat exchanger by its own pressure to cool to 35°C to obtain a liquefied liquid. Afterwards, pump the liquefied liquid to the ...

Embodiment 3

[0026] Weigh 2800kg of 40-mesh glutinous rice flour, 800kg of japonica rice flour and 400kg of sorghum flour respectively, and mix the powder materials with 10t of water through a water-powder mixer. Use a high-pressure pump to quickly inject the adjusted slurry into the high-pressure injector. The pressure of the slurry and the superheated steam pressure are 0.3MPa and 0.8MPa respectively, and the density of the superheated steam is 4.3kg / m 3, the spraying temperature is controlled at 162°C, keep warm in the serpentine tube for 15min, adjust the pH to 6.0 after vacuum flash cooling to 95°C, add 1200g of high-temperature-resistant α-amylase and 240g of activator, mix well and keep warm for 25min, then liquefy The reaction of liquid iodine is light red, with a DE value of 12%. Then the enzyme is sprayed at a temperature of 135°C, and then enters the plate heat exchanger by its own pressure and cools to 35°C to obtain a liquefied liquid. Then pump the liquefied liquid to the fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com