High-rise laminated rainwater pipe and method of making the same

A technology for pipes and rainwater, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of poor thermal stability of PVC resin, harsh processing conditions, poor low temperature resistance, etc., to overcome melt fracture and shorten plastic The effect of saving time and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

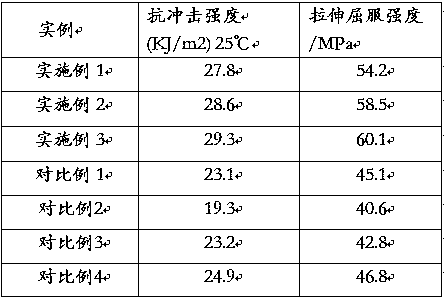

Examples

Embodiment 1

[0063] A polyvinyl chloride pipe for pressure-resistant drainage, in terms of mass fraction, is composed of the following components:

[0064] 80 parts of polyvinyl chloride resin;

[0065] 1 part of organotin stabilizer;

[0066] 1 part of stearic acid;

[0067] 1 copy of modified ACR;

[0068] 2 parts of titanium dioxide;

[0069] 2 parts of modified nano calcium carbonate;

[0070] Wherein the organotin stabilizer can be one of maleate, mercaptan, and thiol fatty acid salt; the polyvinyl chloride resin model is ethylene hair SG-5 resin;

[0071] The preparation method of the modified ACR in the raw material is:

[0072] (1) Preparation of seed emulsion: In terms of mass fraction, 10 parts of butyl acrylate and 5 parts of styrene were added to the reactor as monomers, and 0.5 parts of sodium dodecyl sulfate emulsifier and 0.1 part of potassium persulfate were added to initiate the reaction. agent, stir and heat up to 40 ℃~50 ℃ to prepare seed emulsion;

[0073] (2) Pr...

Embodiment 2

[0083] A high-rise laminated rainwater pipe, in terms of mass fraction, is composed of the following components:

[0084] 85 parts of polyvinyl chloride resin;

[0085] 5 parts of lead stabilizer;

[0086] 3 parts of stearic acid;

[0087] 5 copies of modified ACR;

[0088] 5 parts of titanium dioxide;

[0089] 6 parts of modified nano calcium carbonate;

[0090] Wherein the organotin stabilizer can be one of tribasic lead sulfate, dibasic lead phosphite, and lead stearate;

[0091] The preparation method of the modified ACR in the raw material is:

[0092] (1) Preparation of seed emulsion: In terms of mass fraction, in the reactor, add 15 parts of butyl acrylate and 10 parts of styrene as monomers, add 2.5 parts of sodium dodecyl sulfate emulsifier, 0.5 parts of potassium persulfate The initiator is stirred and heated to 40°C to 50°C to prepare the seed emulsion;

[0093] (2) Preparation of inner core: On the basis of the above seed emulsion, continue to add 0.15 parts...

Embodiment 3

[0103] A high-rise laminated rainwater pipe, in terms of mass fraction, is composed of the following components:

[0104] 90 parts of polyvinyl chloride resin;

[0105] 10 parts of calcium zinc stabilizer;

[0106] 5 parts of stearic acid;

[0107] 10 copies of modified ACR;

[0108] 8 parts of titanium dioxide;

[0109] 10 parts of modified nano calcium carbonate;

[0110] The preparation method of the modified ACR in the raw material is:

[0111] (1) Preparation of seed emulsion: In terms of mass fraction, in the reactor, add 20 parts of butyl acrylate and 15 parts of styrene as monomers, add 5 parts of sodium dodecyl sulfate emulsifier, 0.8 parts of potassium persulfate The initiator is stirred and heated to 40°C to 50°C to prepare the seed emulsion;

[0112] (2) Preparation of inner core: On the basis of the above seed emulsion, continue to add 0.3 parts of potassium persulfate initiator, and at the same time continue to add 60 parts of butyl acrylate and 25 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com