Fluorescent-labeled phosphinoacrylic acid itaconic acid copolymer and its preparation method and use

A technology of phosphino-acrylic itaconic acid copolymer and phosphino-acrylic itaconic acid, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the limitation of development and application, Reaction raw materials are rare, decomposition and other problems, to achieve the effect of online dosing, simplifying on-site operations, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Weigh 10 g (36.09 mmol) of 4-bromo-1,8-naphthalene anhydride into a three-necked flask, add 30 mL of ethanol, stir slowly, and dropwise add N,N-dimethyl-1,3-propylenediamine 9.1 The mixed solution of mL (72.18mmol) and 20mL ethanol was dripped in half an hour, and slowly rose to reflux temperature at the same time, followed by thin-layer chromatography until the reaction was completed, cooled and filtered to obtain a yellow solid, and recrystallized from ethanol to obtain the target product ( I).

[0034]Weigh 5 g (13.84 mmol) of the product (I) generated above in a three-necked flask, add 20 mL of ethylene glycol methyl ether, stir slowly, add dropwise a mixture of 2.7 mL (27.7 mmol) of n-butylamine and 10 mL of ethanol, and simultaneously Slowly rise to 130°C, followed by thin-layer chromatography until the end of the reaction, suction filtration under reduced pressure to remove excess ethylene glycol methyl ether, DMF recrystallization, to obtain the target...

Embodiment 2

[0037] Example 2 Put 90mL of deionized water, 46.8g (0.36mol) of itaconic acid, 0.0276g (0.1mmol) of catalyst, sodium hypophosphite into a four-necked flask equipped with a separating funnel, a thermometer and a reflux condenser. 8.5g (0.08mol) and 0.04g of fluorescent monomer (FT), heated up to reflux (100°C) under stirring, passed nitrogen to remove oxygen, and under the protection of nitrogen, added dropwise a certain amount of ammonium persulfate 10ml (0.684 g ammonium persulfate, accounting for about 1.3% of the mass of the monomer), 5.76g (0.04mol) of acrylic acid and 23ml of sodium bisulfite solution (4.16g accounting for about 8% of the mass of the monomer), drop it within 3.5h, and continue to keep warm 1.5h, cooling discharge, promptly gets product FT-AA-IA (brown liquid) of the present invention

Embodiment 3

[0038] Example 3 Put 80mL of deionized water, itaconic acid 41.6g (0.32mol), catalyst 0.0276g (0.1mmol), sodium hypophosphite into a four-necked flask equipped with a separatory funnel, a thermometer and a reflux condenser. 8.5g (0.08mol) and 0.4g of fluorescent monomer (FT), heated up to reflux (100°C) under stirring, passed nitrogen to remove oxygen, and under the protection of nitrogen, added dropwise a certain amount of ammonium persulfate 20ml (0.75 g ammonium persulfate, accounting for about 1.5% of the mass of the monomer), 8.64g (0.06mol) of acrylic acid and 23ml of sodium bisulfite solution (5.0g accounting for about 10% of the mass of the monomer), drop it within 3h, and continue to keep warm for 2h , cooling discharge, promptly get product FT‐AA‐IA (brown liquid) of the present invention

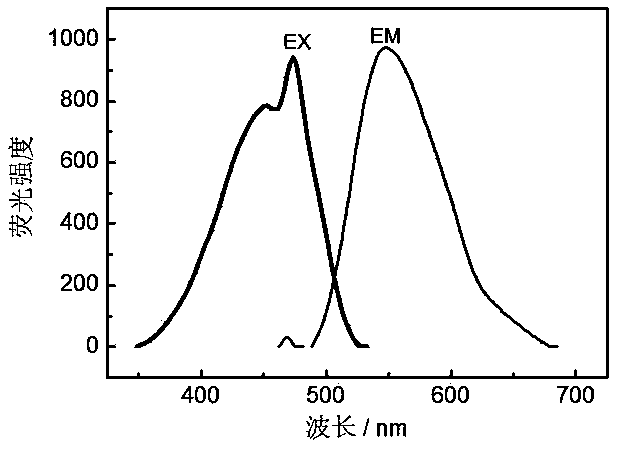

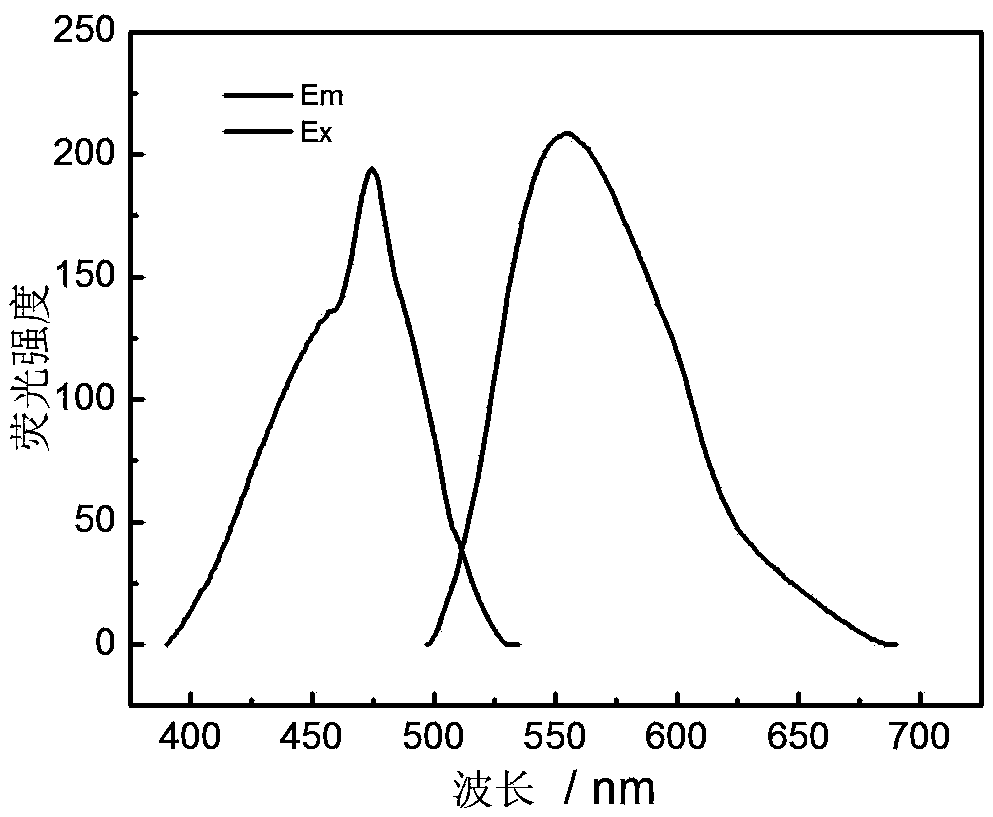

[0039] The excitation wavelength and emission wavelength of the polymer are similar to those of the fluorescent monomer, which are also 474nm and 554nm respectively. image 3 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com