Sulfur, nitrogen and transition metal doped graphene, preparation method and application thereof

A transition metal and graphene technology, applied in the field of electrochemistry, can solve the problems of relatively high corrosion resistance of equipment and environmental pollution, and achieve the effects of excellent catalytic performance, environmental friendliness, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of above-mentioned sulfur, nitrogen, transition metal doped graphene comprises the following steps:

[0026] 1) Add graphene or graphite oxide, transition metal compound, nitrogen-containing compound and sulfur-containing compound into the solvent, mix well, then dry and grind to obtain solid powder;

[0027] 2) Place the solid powder in step 1) in a vacuum or an inert gas, raise the temperature to 350-1200°C at a heating rate of 3-10°C / min, keep it warm for 0.5-6h, and then lower the temperature at a rate of 3-10°C / min Cool down to room temperature to obtain sulfur, nitrogen, and transition metal doped graphene.

[0028] Preferably, the mass ratio of graphene or graphite oxide, transition metal compound, nitrogen-containing compound, and sulfur-containing compound in step 1) is 1:0.1-2:0.1-5:0.1-5.

[0029] Preferably, the mass volume ratio of the graphene or graphite oxide and the solvent in step 1) is 1 g: 100-1000 mL.

[0030] Preferably, th...

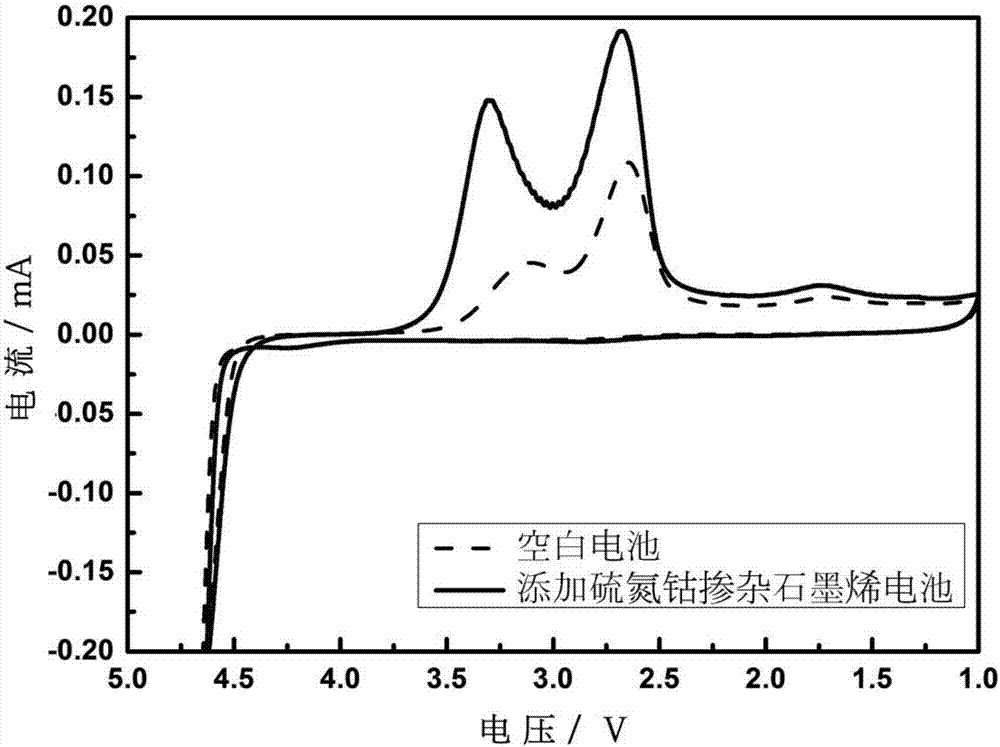

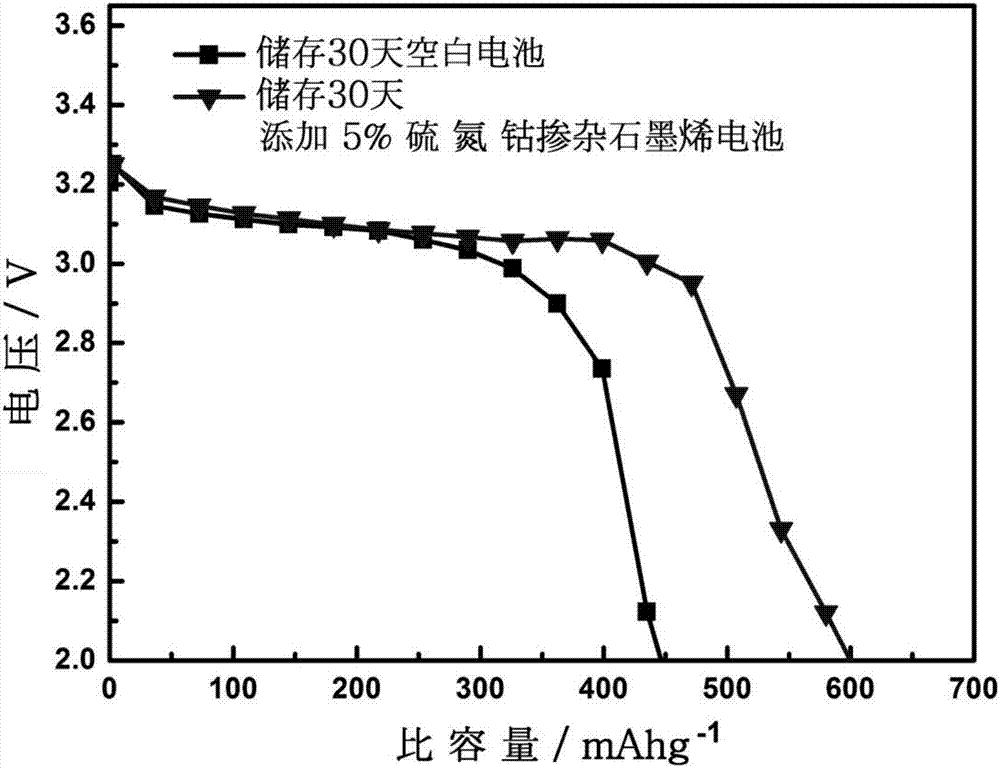

Embodiment 1

[0038] Weigh 0.3g of graphene, 0.3g of cobalt acetate, 0.3g of phthalocyanine and 0.3g of dibenzyl disulfide into 40mL of ethanol solution. After drying for 2 hours in a vacuum oven, dry it in a vacuum oven for 10 hours; grind the obtained product into powder, put it into a porcelain boat and put it into a tube furnace for pyrolysis, raise the temperature to 900 ° C at a heating rate of 5 min / ° C in an argon atmosphere, and Keep it warm for 1 hour, and then cool down to room temperature at a cooling rate of 5°C / min to obtain cobalt-sulfur-nitrogen-doped graphene.

Embodiment 2

[0040] Weigh 0.1g of graphene, 0.2g of cobalt acetate, 0.3g of phthalocyanine and 0.3g of dibenzyl disulfide, add them into 40mL of isopropanol solution, stir and mix evenly, ultrasonicate for 3h, then evaporate the ethanol solution to dryness, After drying in an air oven for 2 hours, dry in a vacuum oven for 10 hours; grind the resulting product into powder, put it into a porcelain boat and put it into a tube furnace for pyrolysis, and heat up to 500°C at a heating rate of 3min / °C in an argon atmosphere , and keep it warm for 5h, and then cool down to room temperature at a cooling rate of 3°C / min to obtain cobalt-sulfur-nitrogen-doped graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com