Chemical polishing waste phosphoric acid treatment method and fertilizer preparation method

A technology of chemical polishing and treatment methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as poor sales of calcium hydrogen phosphate market, complicated precipitation and separation, and low added value of products, and achieve obvious Economic and environmental benefits, easy reaction conditions, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

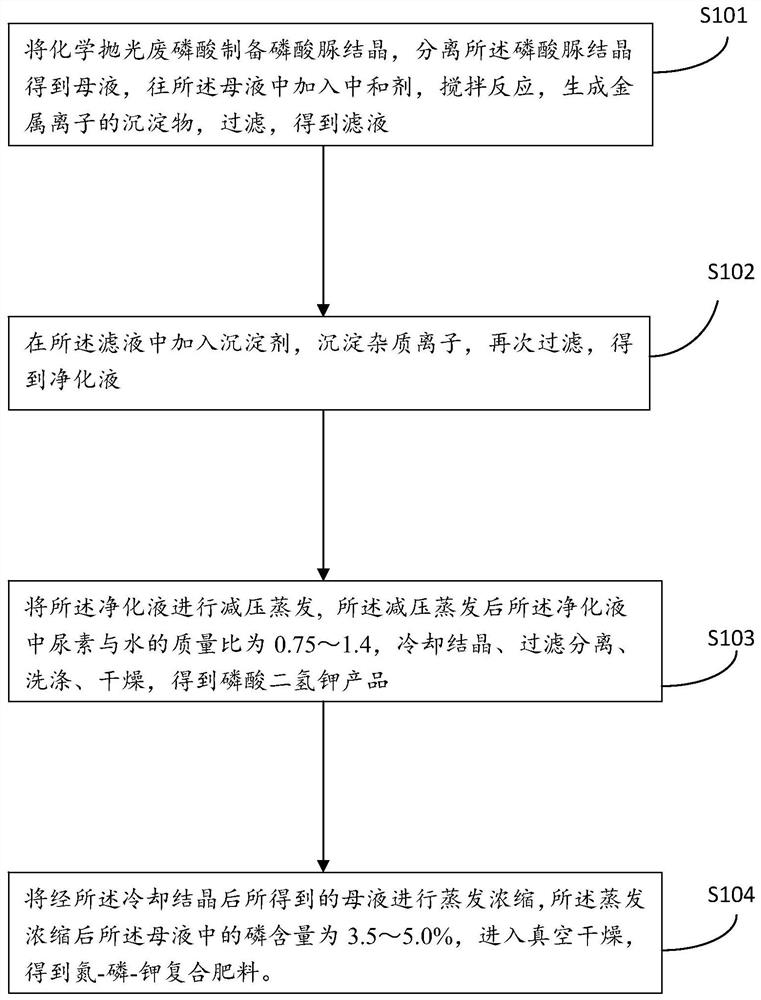

[0043] The present invention also provides a kind of preparation method of potassium dihydrogen phosphate, comprises the following steps:

[0044] Adding a neutralizing agent to the mother liquor of urea phosphate crystallization prepared from chemically polished waste phosphoric acid, stirring and reacting to generate a precipitate of metal ions, and filtering to obtain a filtrate;

[0045]Adding a precipitating agent to the filtrate to precipitate impurity ions, and filtering again to obtain a purified solution;

[0046] Evaporating the purified solution under reduced pressure, the mass ratio of urea to water in the purified solution after the reduced-pressure evaporation is 0.75 to 1.4, cooling and crystallizing to obtain crystals and mother liquor, filtering and separating the crystals, washing and drying, Potassium dihydrogen phosphate product is obtained.

[0047] The potassium dihydrogen phosphate product obtained in the embodiment of the present invention has a direct...

Embodiment 1

[0056] Get chemical polishing waste phosphoric acid to prepare 500mL of urea phosphate crystallization mother liquor, wherein total phosphorus content is 113g / L, total nitrogen is 99.4g / L, sulfate radical 5.6g / L, aluminum content 4.5g / L, iron (Fe) content 23mg / L L, copper (Cu) content 16mg / L, zinc (Zn) content 28mg / L, lead (Pb) content 0.3mg / L.

[0057] Slowly add potassium hydroxide with a concentration of 30% to the mother liquor of urea phosphate crystallization prepared by chemical polishing waste phosphoric acid, control the pH value at about 4.2, stir for 2.0 hours, and filter to remove the precipitates of metal ions such as aluminum;

[0058] In the filtrate of above-mentioned gained, add appropriate amount of barium hydroxide by sulfate radical metering 100% to remove sulfate radical ion, then add by the precipitant potassium sulfide of heavy metal total molar weight 95%, remove part copper (Cu), lead (Pb), Arsenic (As), zinc (Zn), filtered to obtain purified solution;...

Embodiment 2

[0063] Take chemical polishing waste phosphoric acid to prepare 500mL of urea phosphate crystallization mother liquor, wherein total phosphorus content is 115g / L, total nitrogen is 102.1g / L, sulfate radical 2.7g / L, aluminum content 3.5g / L, Fe content 10mg / L, Cu The content is 18mg / L, the Zn content is 31mg / L, and the Pb content is 0.1mg / L.

[0064] Slowly add potassium carbonate with a concentration of 28% to the mother liquor for preparing urea phosphate crystallization from chemically polished waste phosphoric acid, control the pH value at about 4.6, stir for 0.5h, and filter to remove the precipitates of metal ions such as aluminum.

[0065] Add an appropriate amount of barium chloride to remove sulfate ions in the filtrate of the above-mentioned gained by 95% of the sulfate radical metering, then add the precipitant ammonium sulfide according to the total molar weight of heavy metals 100%, remove part of Cu, Pb, As, Zn, and filter to obtain Purifying fluid.

[0066] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com