Anaerobic fermentation compound additive and method for promoting biogas residue and biogas liquid fertilizer anaerobic fermentation

A compound additive, anaerobic fermentation technology, applied in urea compound fertilizer, organic fertilizer, inorganic fertilizer and other directions, can solve the problems of high pollution degree of biogas slurry, less substrate degradation, low gas production rate, etc., to improve the fermentation environment, The effect of promoting degradation and increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

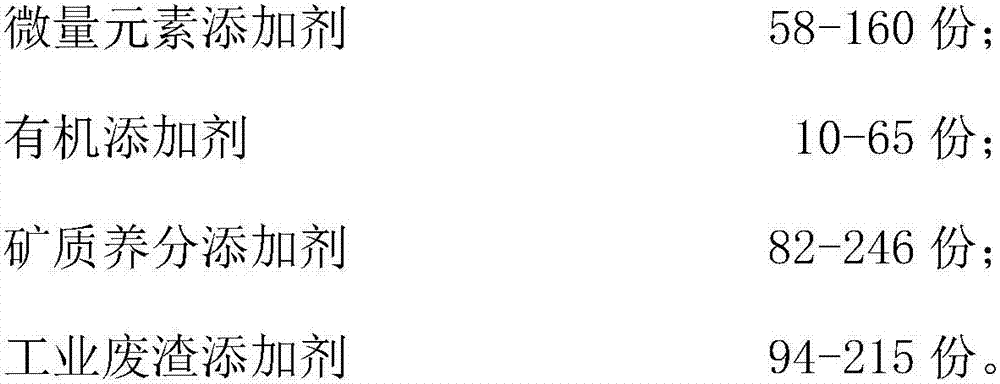

[0041] The preparation method of the anaerobic fermentation compound additive provided by the present invention:

[0042] Mix 58-160 parts of trace element additives, 10-65 parts of organic additives, 82-246 parts of mineral nutrient additives, and 94-215 parts of industrial waste slag additives at room temperature. Oxygen fermentation compound additive.

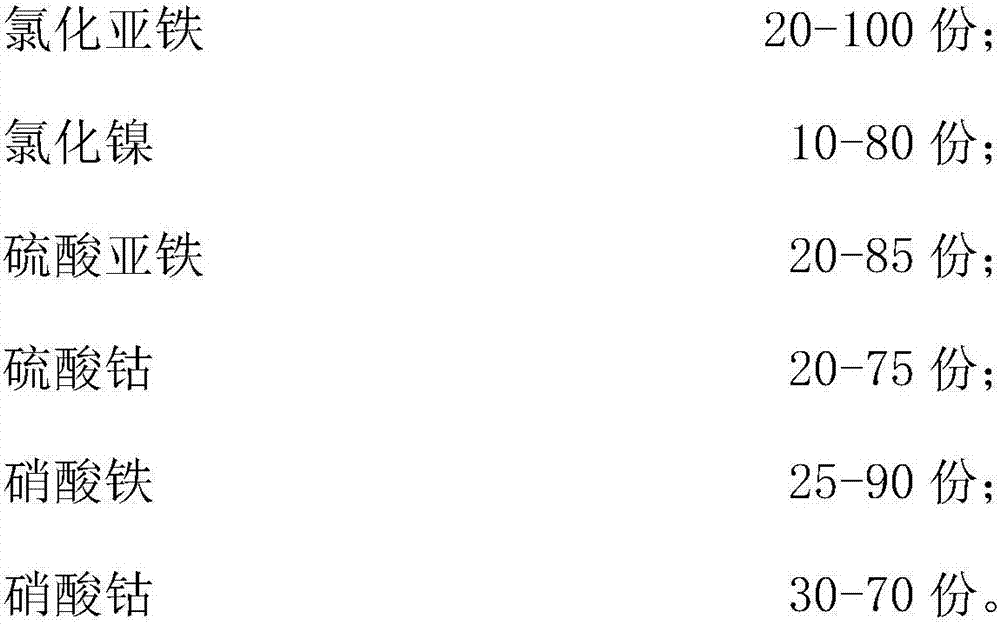

[0043] Among them, the trace element additives include the following raw materials by mass: 20-100 parts of ferrous chloride; 10-80 parts of nickel chloride; 20-85 parts of ferrous sulfate; 20-75 parts of cobalt sulfate; 25-90 parts of iron nitrate Parts; 30-70 parts of cobalt nitrate.

[0044] Among them, the organic additives include the following raw materials in parts by mass: 5-28 parts of urea; 10-50 parts of ammonium dihydrogen phosphate; 10-45 parts of citric acid.

[0045] Among them, the mineral nutrient additives include the following parts by mass of raw materials: 65-210 parts of plant ash; 40-150 parts of activated ca...

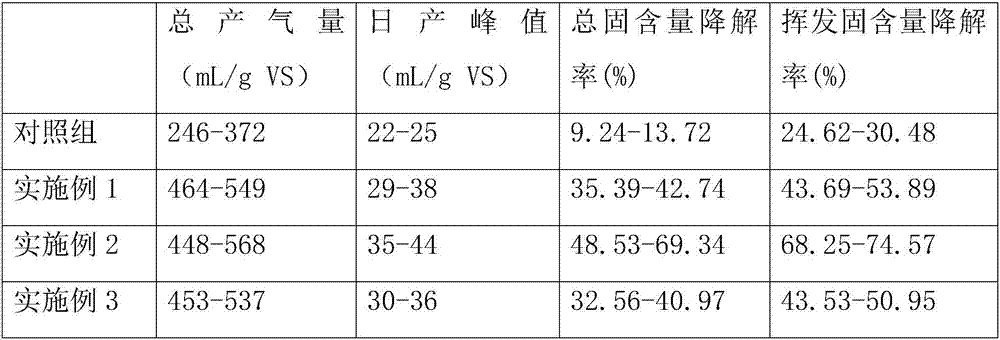

Embodiment 1

[0057] (1) Preparation of anaerobic fermentation compound additives:

[0058] Trace element additives, 30 parts of ferrous chloride, 45 parts of nickel chloride, 45 parts of ferrous sulfate, 75 parts of cobalt sulfate, 90 parts of iron nitrate, 70 parts of cobalt nitrate; organic additives: 5 parts of urea, 10 parts of diammonium hydrogen phosphate , 45 parts of citric acid; 165 parts of mineral nutrient additives, plant ash, 40 parts of activated carbon, 165 parts of bentonite; 15 parts of industrial waste slag additives, low-carbon steel slag microcrystalline powder, and 90 parts of medium-carbon steel steel slag microcrystalline powder.

[0059] (2) Start the fermentation system to produce biogas and collect biogas residue and liquid:

[0060] Mix 200 parts of poultry manure and 350 parts of inoculum sludge according to the mass parts, add 260 parts of compound additives to prepare a fermentation feed liquid, adjust the fermentation feed liquid to a solid content of 6% and a pH of...

Embodiment 2

[0065] (1) Preparation of anaerobic fermentation compound additives:

[0066] Trace element additives, 85 parts of ferrous chloride, 10 parts of nickel chloride, 85 parts of ferrous sulfate, 20 parts of cobalt sulfate, 40 parts of iron nitrate, 45 parts of cobalt nitrate; 28 parts of organic additives urea, 25 parts of diammonium hydrogen phosphate , 20 parts of citric acid; 210 parts of mineral nutrient additive plant ash, 150 parts of activated carbon, 100 parts of bentonite; industrial waste slag additive 50 parts of low-carbon steel slag microcrystalline powder, and 25 parts of medium carbon steel slag microcrystalline powder.

[0067] (2) Start the fermentation system to produce biogas and collect biogas residue and liquid:

[0068] According to mass parts, 350 parts of poultry manure and 500 parts of inoculum sludge were mixed, and 385 parts of compound additives were added to prepare a fermentation feed liquid. The fermentation feed liquid was adjusted to a solid content of 8%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com