A refined polysaccharide of Ganoderma lucidum fruiting body with significant auxiliary anti-tumor activity and its preparation method and application

A technology of Ganoderma lucidum fruiting body and anti-tumor activity, which is applied in the fields of extraction and separation technology and application and development of medicine and food, and can solve problems such as failure of normal production, clogging of liquid outlet, and excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Cut the fruit body of Ganoderma lucidum into thin slices or pulverize it properly, add 10 times the weight of edible alcohol for reflux extraction for 2 times, each time for 2 hours, release the extract, and pass steam into the remaining fruit body residue to replace the alcohol residue as much as possible, and air to dry. After basically no alcohol odor, it is dried with hot air below 60°C to obtain pretreated fruit body residues.

[0094] 50kg of fruiting body residues for use, add 500L of purified water, heat to boiling with steam, stir at 15r / min and maintain a slight boil for 3h, turn off the steam, cool to below 50°C, extract the supernatant, and use a 0.8μm filter membrane to plate and frame After filtration, the residue was extracted twice according to the above method, and the crude filtrates were combined. 200nm tubular ceramic microfiltration membrane for crude filtrate (CX-30-1016-4-19 type, 8 parallel, membrane area 1.904m 2 ) for clarification, the operat...

Embodiment 2

[0097] Take 30kg of Ganoderma lucidum fruiting body residue that has been extracted with edible alcohol in advance and then dried for use, add 750L of purified water, heat it to boiling with steam, start the feed pump at intervals of 30min to force circulation for 5min, maintain slight boiling for 2h, turn off the steam, and cool to 50 Below ℃, extract the supernatant, use a bag filter with a filtration precision of 1 μm for coarse filtration, repeat the extraction of the residue once according to the above method, and combine the coarse filtrate. The crude filtrate is finely filtered with a pp microporous pleated filter element with a filtration accuracy of 0.22 μm, and the clarified liquid is collected. 60-100 mesh polyamide resin and D392 anion resin were purified and expanded according to the product instructions in advance, and were packed into columns with packing heights of 1.5m (BV=26.5L) and 30cm (BV=5.3L), respectively. In front) series D392 anion column (in the back...

Embodiment 3

[0100] Determination of protein and polysaccharide content in Ganoderma lucidum fruiting body refined polysaccharide by UV-Vis spectrophotometry, and calculation of polysaccharide retention rate, protein removal rate, and pigment removal rate

[0101] Determination of protein content: BCA method was used for determination. The BCA protein concentration determination kit (enhanced) (EnhancedBCA Protein Assay Kit) was purchased from Shanghai Biyuntian Biotechnology Co., Ltd., and the detection was done according to the detailed instructions.

[0102] Pigment measurement: directly measure the absorbance A value at 400nm with a spectrophotometer.

[0103] Determination of polysaccharide content: Determination by anthrone-sulfuric acid method, according to the steps in "Chinese Pharmacopoeia, 2015 Edition, Ganoderma lucidum [Determination of Content] Polysaccharides".

[0104] Take about 50 mg of the purified polysaccharide from the fruiting body of Ganoderma lucidum prepared in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

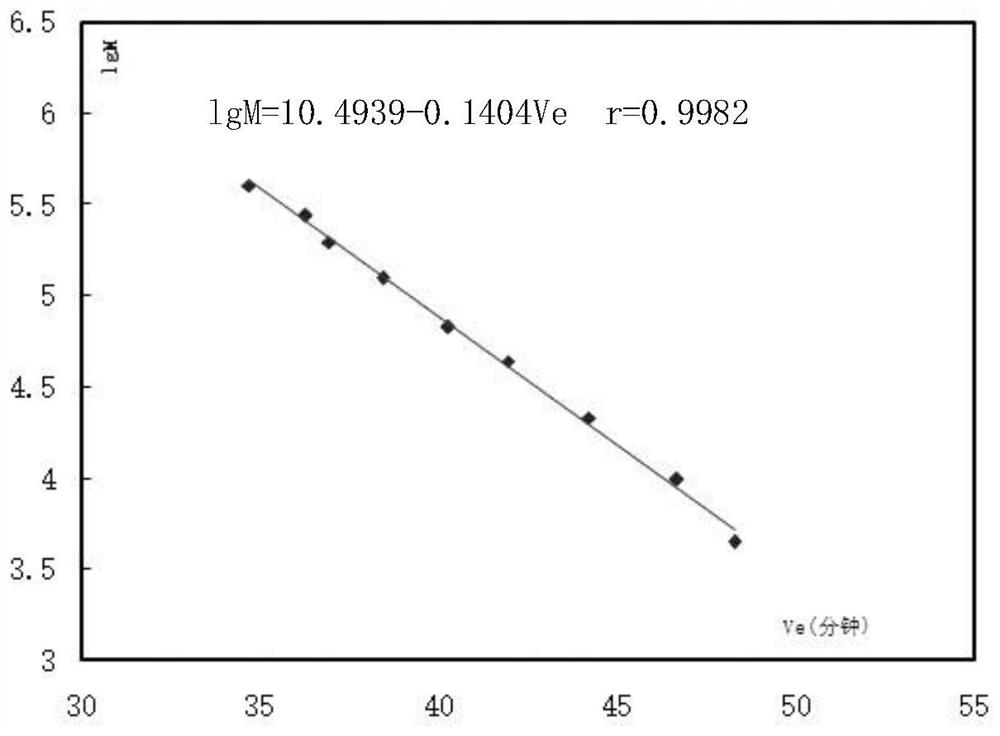

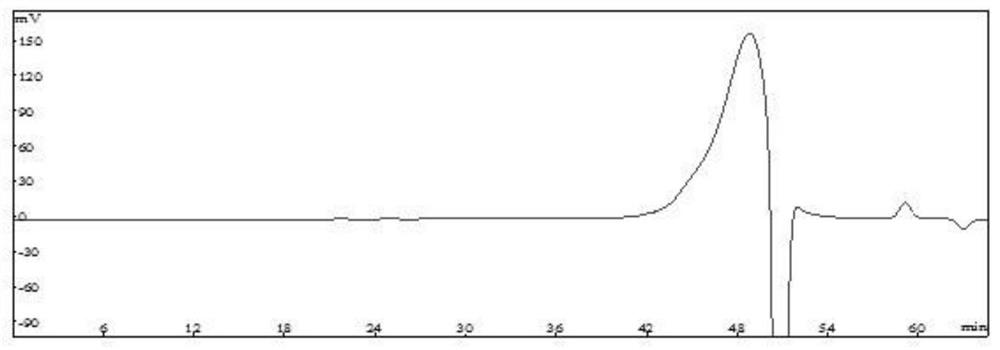

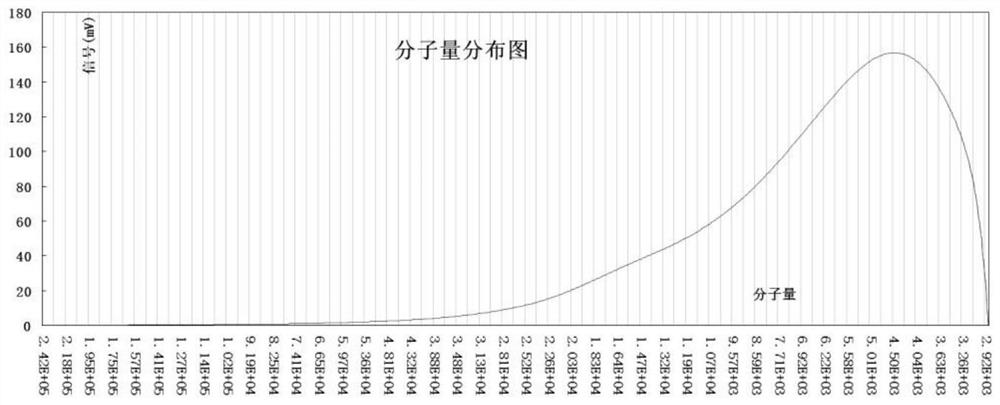

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com