Cefixime dispersible tablets and preparation method thereof

A technology of cefixime and dispersible tablets, which is applied in the field of medicine, can solve the problems of poor solubility of cefixime, slow dissolution of ordinary tablets, unqualified substance inspection, etc., and achieve a product that promotes dissolution and absorption, has a pleasant taste, and is convenient to take Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

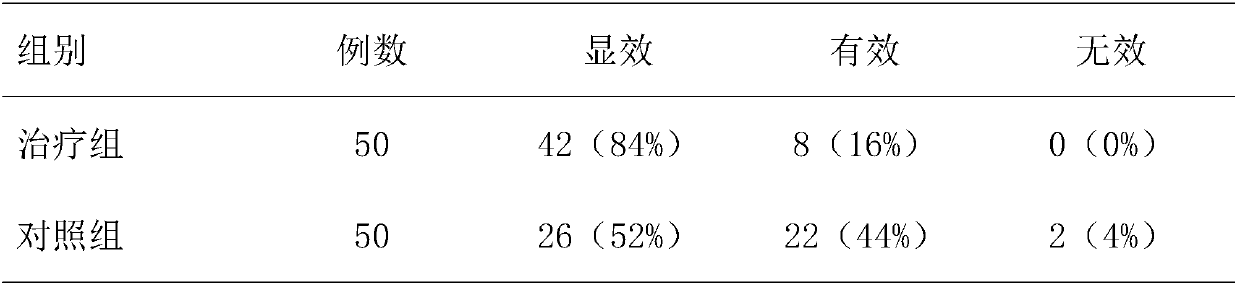

Examples

Embodiment 1

[0022] A cefixime dispersible tablet is made from the following raw materials in weight ratio: 50 parts of cefixime, 0.01 part of polyoxyethylene (20) sorbitan monooleate (Tween 80), 3 parts of loquat dew, 3 parts of disodium glycyrrhizinate, 2 parts of aspartame alitame, 3 parts of xanthan gum, 5 parts of citric acid, 4 parts of pentaerythritol, 2 parts of folded carboxymethyl starch sodium.

[0023] Wherein, the preparation method of xanthan gum is as follows: take 100 parts of corn starch with a moisture content lower than 8%, add 50wt% sterile water to make starch slurry; slowly stir the starch slurry, heat it to 37-42°C, and keep it warm. ; Add 10 to the starch slurry 5 -10 6 cfu / mL Xanthomonas 10mL, aerobically fermented for 36-72h, the fermented product is a high molecular weight, anionic polysaccharide polymer; the product obtained by vacuum drying at low temperature until the water content is less than 10% is the desired xanthan gum .

[0024] Among them, the prepa...

Embodiment 2

[0032] A kind of cefixime dispersible tablet, is made by the raw material of following weight ratio: 60 parts of cefixime, 0.05 part of polyoxyethylene (20) sorbitan monooleate (Tween 80), 5 parts of loquat dew, 5 parts of disodium glycyrrhizinate, 4 parts of aspartame alitame, 5 parts of xanthan gum, 8 parts of citric acid, 6 parts of pentaerythritol, 6 parts of folded carboxymethyl starch sodium.

[0033] Wherein, the preparation method of xanthan gum is as follows: take 100 parts of corn starch with a moisture content lower than 8%, add 50wt% sterile water to make starch slurry; slowly stir the starch slurry, heat it to 37-42°C, and keep it warm. ; Add 10 to the starch slurry 5 -10 6 cfu / mL Xanthomonas 10mL, aerobically fermented for 36-72h, the fermented product is a high molecular weight, anionic polysaccharide polymer; the product obtained by vacuum drying at low temperature until the water content is less than 10% is the desired xanthan gum .

[0034] Among them, the...

Embodiment 3

[0042] A cefixime dispersible tablet, made of the following raw materials in weight ratio: 55 parts of cefixime, 0.04 part of polyoxyethylene (20) sorbitan monooleate (Tween 80), 4 parts of loquat dew, 4 parts of disodium glycyrrhizinate, 3 parts of aspartame alitame, 4 parts of xanthan gum, 6 parts of citric acid, 6 parts of pentaerythritol, 6 parts of folded carboxymethyl starch sodium.

[0043] Wherein, the preparation method of xanthan gum is as follows: take 100 parts of soybean starch with a moisture content lower than 8%, add 50wt% sterile water to make starch slurry; slowly stir the starch slurry, heat it to 37-42°C, and keep it warm ; Add 10 to the starch slurry 5 -10 6 cfu / mL Xanthomonas 10mL, aerobically fermented for 36-72h, the fermented product is a high molecular weight, anionic polysaccharide polymer; the product obtained by vacuum drying at low temperature until the water content is less than 10% is the desired xanthan gum .

[0044] Among them, the prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com