An activated carbon fiber loaded with co 3 o 4 Preparation method of catalytic material

A technology of activated carbon fibers and catalytic materials, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve AC regeneration difficulties, azo dye wastewater concentration, color High pH, reducing sunlight and other problems, to achieve the effect of adapting to a wide range of pH, easy to operate the preparation method, and easy to industrialize preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

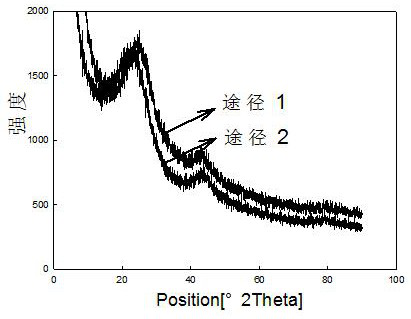

[0031] Embodiment 1: (Route 1)

[0032] An activated carbon fiber loaded with Co 3 o 4A method for preparing a catalytic material, the method comprising the following steps:

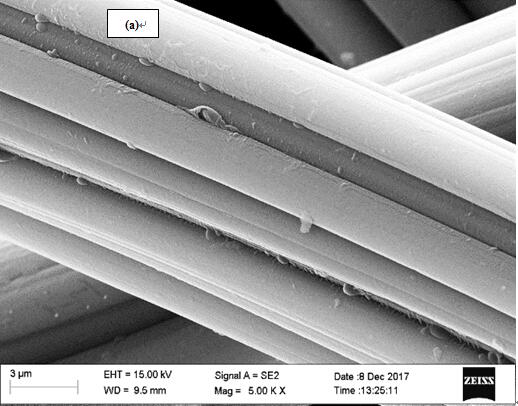

[0033] 1.1) Activated carbon fiber pretreatment: take 20g activated carbon fiber, put it into nitric acid solution (concentration is 3M), soak 24h at room temperature, take out ACF and wash several times with distilled water, measure the washing solution with pH test paper until it is neutral, Dry in a drying oven at 105°C;

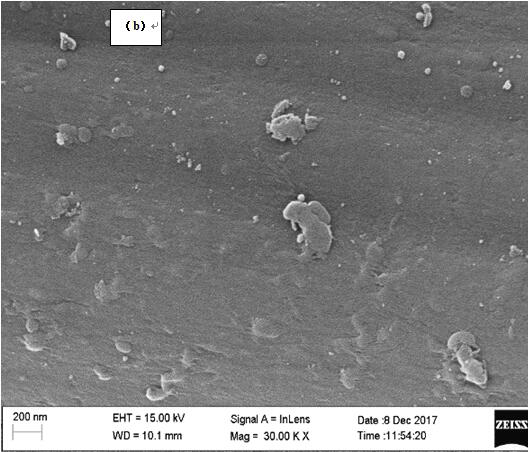

[0034] 1.2) Weigh 0.04g Co(NO 3 ) 2 ·6H 2 O and 0.05g NaNO 3 Add it into a 200mL n-hexanol beaker, stir magnetically at room temperature for 2h until evenly mixed, transfer it to a round bottom flask, add 0.6g of pretreated activated carbon fiber to the round bottom flask, soak for 10h, then heat under reflux in an oil bath, heat The temperature was 140°C, and the reflux heating time was 12h. After the reaction, it was naturally cooled, and the ACF was taken out and washed 4 ...

Embodiment 2

[0036] Embodiment 2: (approach 2)

[0037] An activated carbon fiber loaded with Co 3 o 4 A method for preparing a catalytic material, the method comprising the following steps:

[0038] 2.1) Activated carbon fiber pretreatment: Weigh 20g of activated carbon fiber, put it into nitric acid solution (3M), soak it at room temperature for 24 hours, take out the ACF and wash it with distilled water for several times, use pH test paper to measure the washing solution until it is neutral, put it into Dry in a drying oven at 105°C;

[0039] 2.2) Dissolve 0.2mmol of cobalt nitrate hexahydrate, 1mmol of ammonium fluoride, and 2mmol of urea in 40mL of distilled water, transfer them together with 0.6g of pretreated activated carbon fibers to a 50mL reaction kettle, and place the reaction kettle at 120°C In the drying oven, hydrothermal reaction was carried out for 5 hours. After the hydrothermal reaction, the reactor was taken out and cooled naturally. The activated carbon fiber was ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com