Electrochemical sensor based on biomass carbon and preparation method and electrocatalysis application thereof

A technology of biomass carbon and electrochemistry, applied in the field of electrochemistry, can solve the problems of long production cycle and cumbersome operation steps, and achieve the effects of low equipment corrosion, large overpotential and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]The electrochemical sensor based on biomass carbon in this embodiment is constructed by using a biomass nanoporous material-modified electrode as a working electrode, a saturated calomel electrode as a reference electrode, and a platinum wire electrode as an auxiliary electrode.

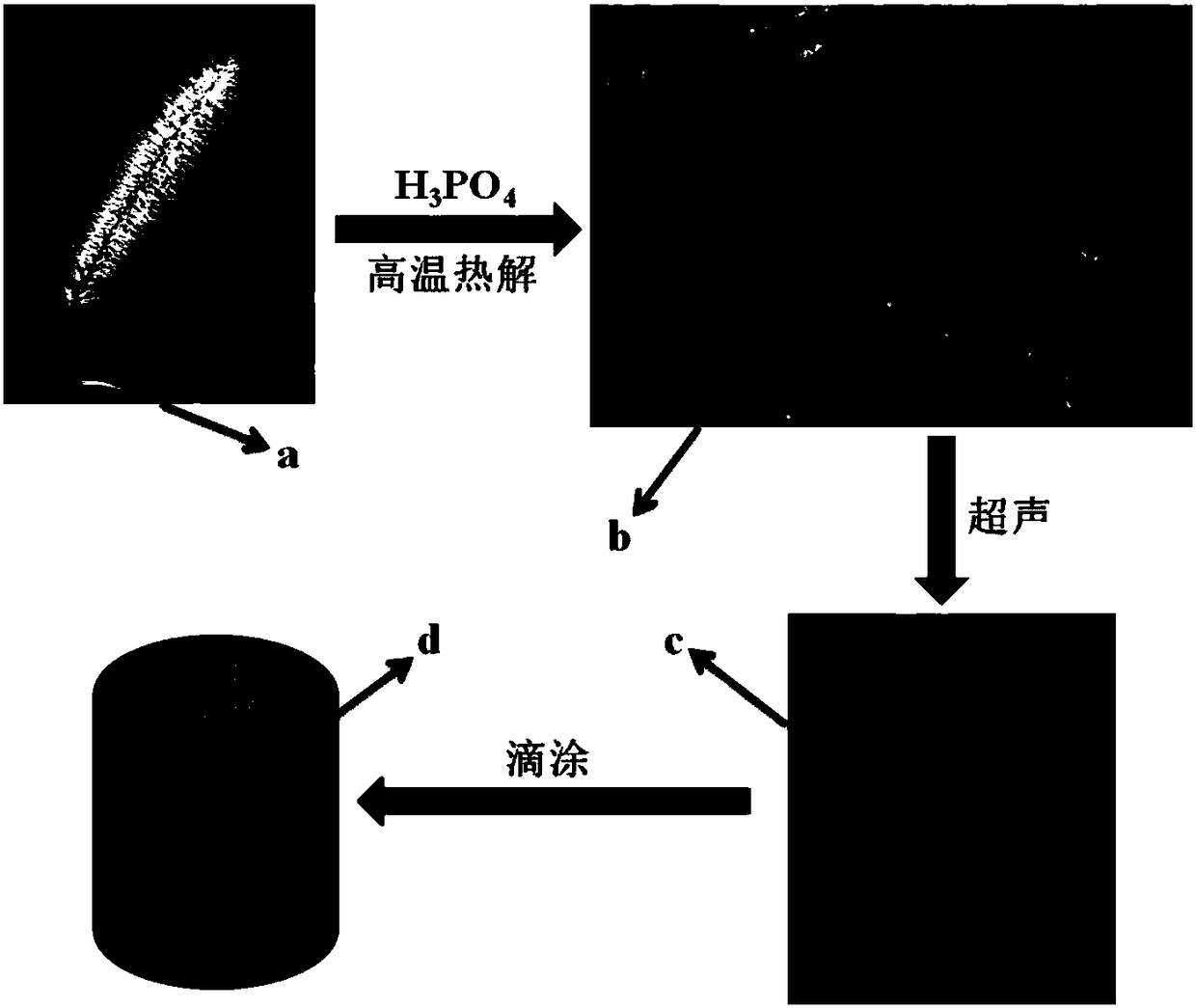

[0046] The preparation of the biomass nanoporous material in this embodiment, the preparation process is as follows:

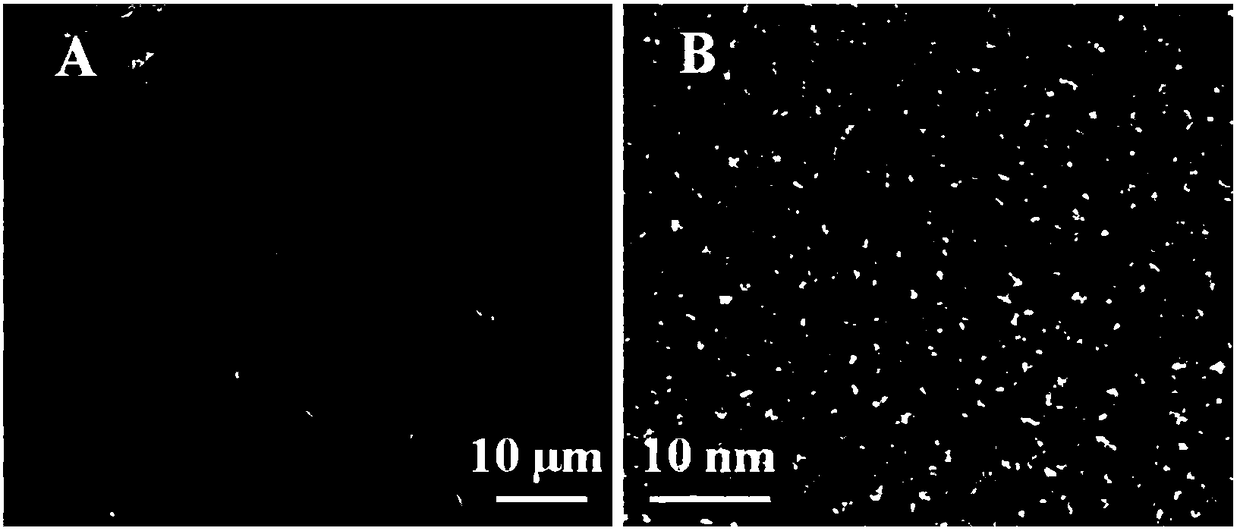

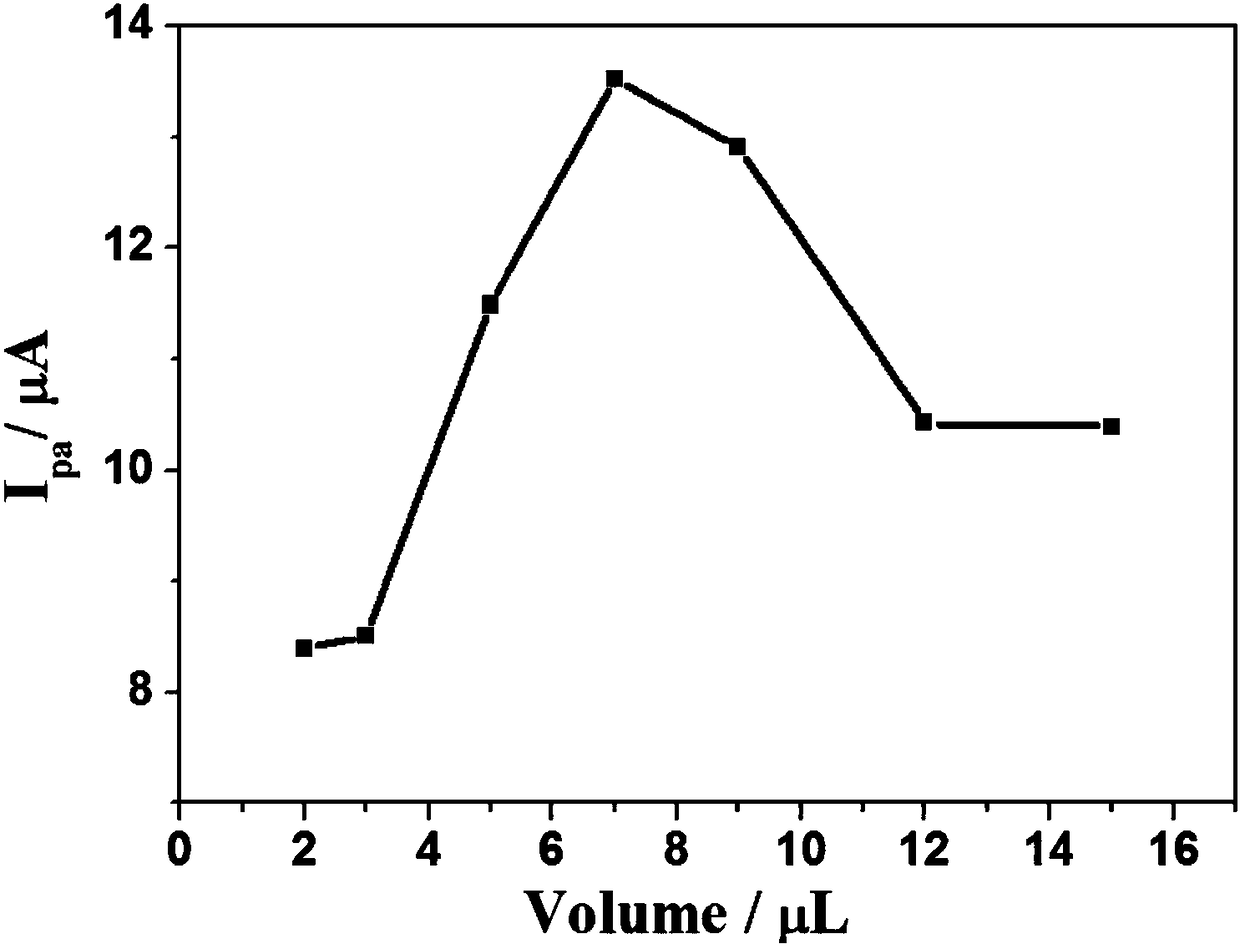

[0047] Soak the foxtail cilia with acetone for 1 hour, then ultrasonically clean it with distilled water for 3-4 times, put it in an oven and dry it, weigh 2 g of the washed, dried and chopped foxtail cilia, add it to 12 mL of phosphoric acid (50%), and stir at room temperature for 12 hours After that, vacuum dry. Subsequently, the obtained acid-etched Foxtail cilia was transferred to a tube furnace, and argon was introduced, and the temperature was first raised to 150°C at a heating rate of 5°C / min, kept for 6 hours, and then continued to heat up at a heating rate of 10°C / min ...

Embodiment 2

[0051] This embodiment is based on the electrochemical sensor of biomass carbon, and its preparation process is specifically the same as that of Example 1, the only difference being that the solid-liquid ratio of foxtail cilia and 50% phosphoric acid solution is different in the process of preparing biomass nanoporous materials , the solid-liquid ratio of Foxtail cilia and 50% phosphoric acid solution in this example is 1g:8mL.

Embodiment 3

[0053] This embodiment is based on the electrochemical sensor of biomass carbon, and its preparation process is the same as that of Embodiment 1, the only difference is: the process of preparing biomass nanoporous materials is different, and the specific process of this embodiment is as follows:

[0054] Soak the foxtail cilia with acetone for 1 hour, then ultrasonically clean it with distilled water for 3-4 times, put it in an oven and dry it, weigh 2 g of the washed, dried and chopped foxtail cilia, add it to 12 mL of phosphoric acid (50%), and stir at room temperature for 12 hours After that, vacuum dry. Subsequently, the obtained acid-etched Foxtail cilia was transferred to a tube furnace, and argon was introduced, and the temperature was first raised to 150°C at a heating rate of 5°C / min, kept for 6 hours, and then continued to heat up at a heating rate of 10°C / min To 550°C, keep warm for 1h. Then, the product obtained by high-temperature pyrolysis was cooled to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Peak current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com