Preparation method of spherical N-doped C-coated metal oxide negative electrode material with multi-stage structure

A negative electrode material and oxide technology, which is applied in the field of preparation of spherical N-doped C-coated metal oxide negative electrode materials, can solve the problems of material loss of activity, poor NiO cycle performance, poor conductivity, etc. Uniform, wide potential window reversible capacity, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

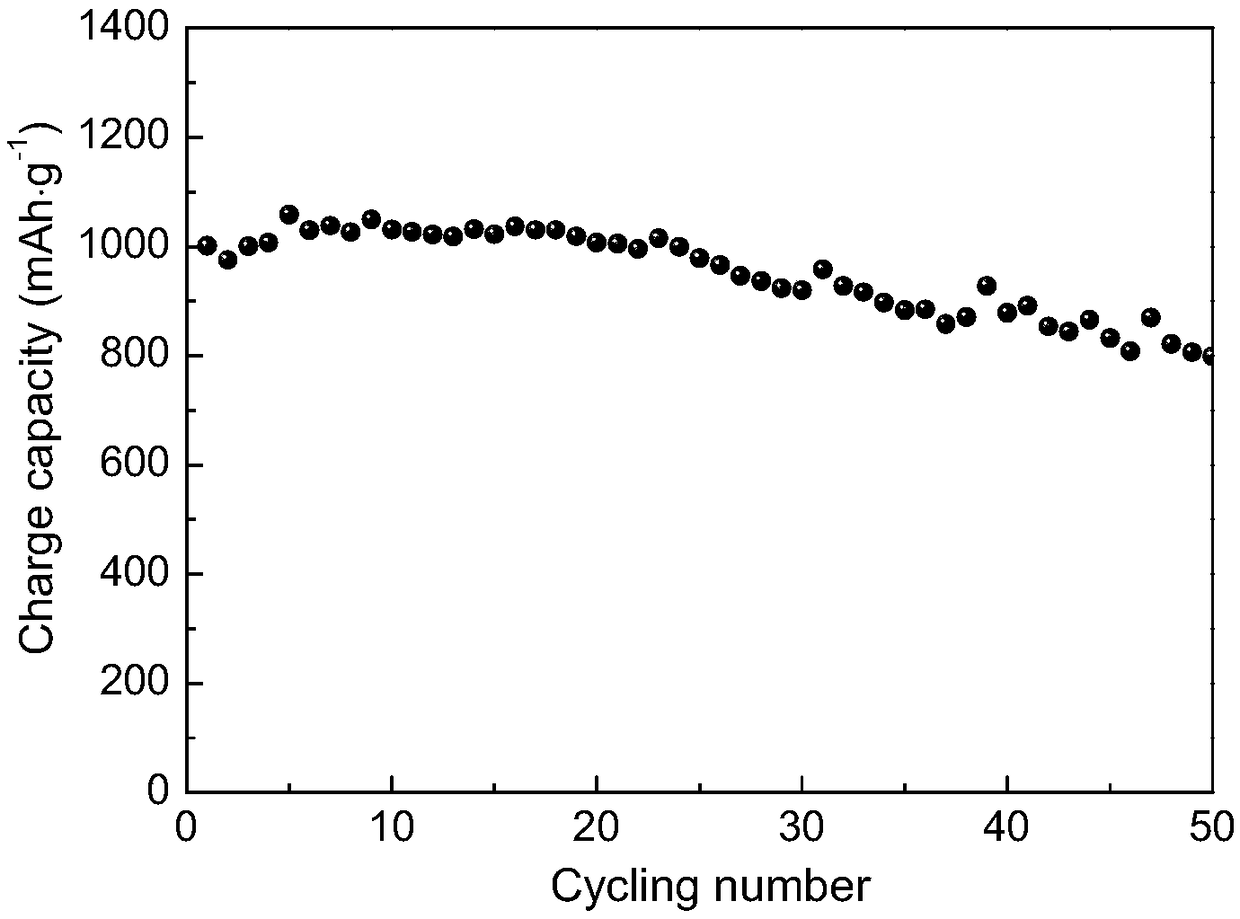

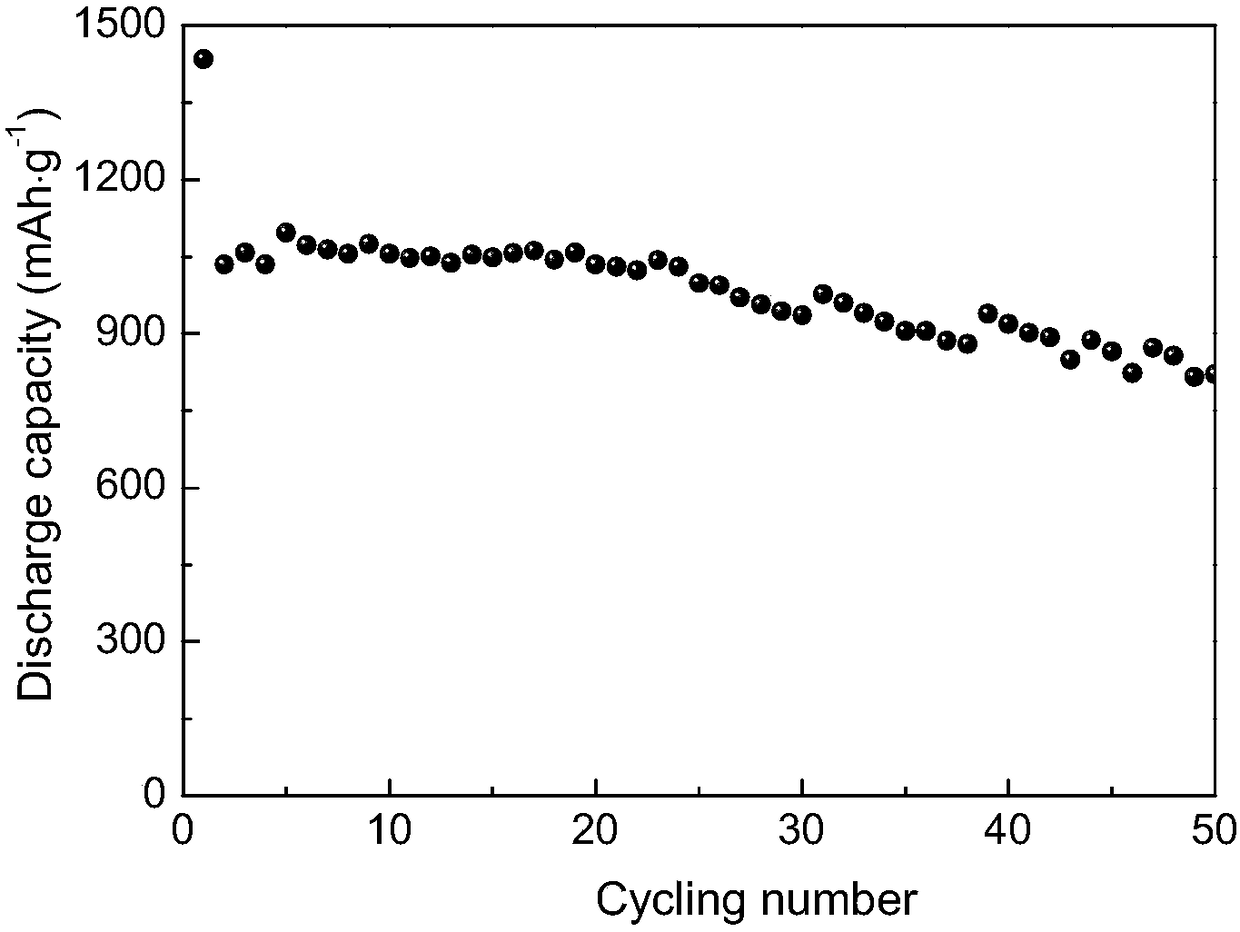

Embodiment 1

[0024] Dissolve 0.15g of polyvinylidene fluoride and 0.2g of guanidine hydrochloride in 2.85g of N-methylpyrrolidone, stir and mix, dry and calcinate, grind and pass through a fine sieve to obtain N-doped C powder. Dissolve sodium molybdate, nickel nitrate, ammonium fluoride and urea in a mixed solution of ethanol and water with a volume ratio of 1:3, stir for 1 hour, then transfer to a reaction kettle for 12 hours at 120°C, cool to room temperature, and filter , washed 4 times with a mixed solution of deionized water and ethanol, and dried at 60°C to obtain a precursor; then N-doped C powder was mixed with the precursor, ball milled, and put into a tube furnace in a nitrogen-argon gas mixture ( NiO / NiMoO 4 @N-C material. Will take 500mg of NiO / NiMoO obtained 4 @C material was put into 50mL distilled water, and ultrasonically dispersed for 2h, then 10mg sodium dodecylbenzenesulfonate was added as a surfactant, and stirred for 12h. Add 0.035mL pyrrole and 0.5mL1mol / L hydroch...

Embodiment 2

[0026]Dissolve 0.15g of polyvinylidene fluoride and 0.2g of guanidine hydrochloride in 2.85g of N-methylpyrrolidone, stir and mix, dry and calcinate, grind and pass through a fine sieve to obtain N-doped C powder. Dissolve sodium molybdate, nickel nitrate, ammonium fluoride and urea in a mixed solution of ethanol and water with a volume ratio of 1:3, stir for 1 hour, then transfer to a reaction kettle for 12 hours at 100°C, cool to room temperature, and filter , washed 4 times with a mixed solution of deionized water and ethanol, and dried at 60°C to obtain a precursor; then N-doped C powder was mixed with the precursor, ball milled, and put into a tube furnace in a nitrogen-argon gas mixture ( NiO / NiMoO 4 @N-C material. Will take 500mg of NiO / NiMoO obtained 4 The @N-C material was put into 50mL distilled water and ultrasonically dispersed for 2h, then 10mg sodium dodecylbenzenesulfonate was added as a surfactant, and stirred for 12h. Add 0.035mL pyrrole and 0.5mL1mol / L hyd...

Embodiment 3

[0028] Dissolve 0.15g of polyvinylidene fluoride and 0.2g of guanidine hydrochloride in 2.85g of N-methylpyrrolidone, stir and mix, dry and calcinate, grind and pass through a fine sieve to obtain N-doped C powder. Dissolve sodium molybdate, nickel nitrate, ammonium fluoride and urea in a mixed solution of ethanol and water with a volume ratio of 1:3, stir for 1 hour, then transfer to a reaction kettle for 8 hours at 160°C, cool to room temperature, and filter , washed 4 times with a mixed solution of deionized water and ethanol, and dried at 60°C to obtain a precursor; then N-doped C powder was mixed with the precursor, ball milled, and put into a tube furnace in a nitrogen-argon gas mixture ( NiO / NiMoO 4 @N-C material. Will take 500mg of NiO / NiMoO obtained 4 The @N-C material was put into 50mL of distilled water and ultrasonically dispersed for 2h, then 10mg of sodium dodecylbenzenesulfonate was added as a surfactant, and stirred for 12h. Add 0.035mL pyrrole and 0.5mL1mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com