Microwave dielectric ceramic powder filled fluororesin intermediate dielectric layer and preparation method thereof

A technology of microwave dielectric ceramics and dielectric layers, applied in dielectric materials, chemical instruments and methods, printed circuit dielectrics, etc., can solve the problems of low dielectric constant, weaken material deformation ability, reduce thermal expansion coefficient, etc., and achieve low dielectric constant temperature coefficient, the effect of improving the efficiency of mass production, and improving the coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

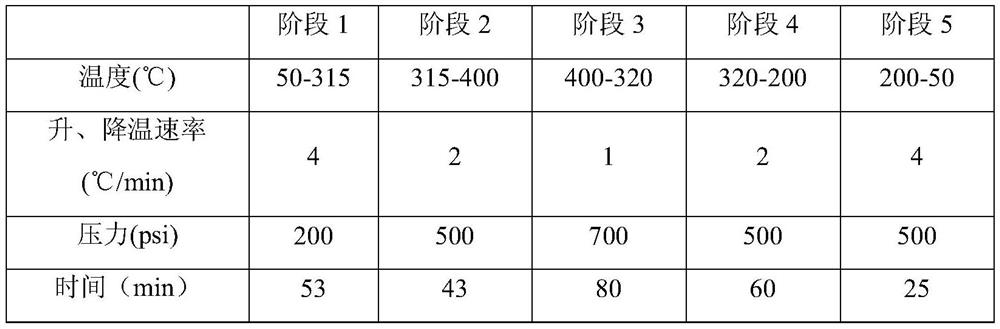

Embodiment 1

[0051] Weigh 750 grams of microwave dielectric ceramic powder (D50 particle size 5um, dielectric constant 100); ground glass fiber powder 50g; fluororesin concentrated dispersion Daikin D210 (solid content 60wt%, particle size: 0.1 μm-0.5 μm ) 303g; PFA (solid content 60wt%, particle size between 0.1 μm-0.5 μm) 30g; surfactant TEGO 755 75 grams, distilled water 750ml.

[0052] The microwave medium ceramic powder is added into water to form a dispersion liquid; then a surfactant and an inorganic reinforcing filler are added; after ball milling, a fluororesin dispersion liquid is added and mixed to obtain a stable water-based emulsion. Ball milling involves high-speed stirring in a sand mill for 60-120 minutes at a speed of 1000r / min until a stable aqueous suspension emulsion is formed, and ceramic and filler particles do not agglomerate or settle in the emulsion. Transfer the above aqueous suspoemulsion to a spray drying machine, and undergo cyclone separation at high temperatu...

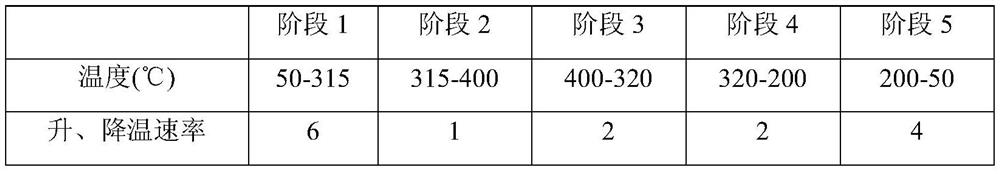

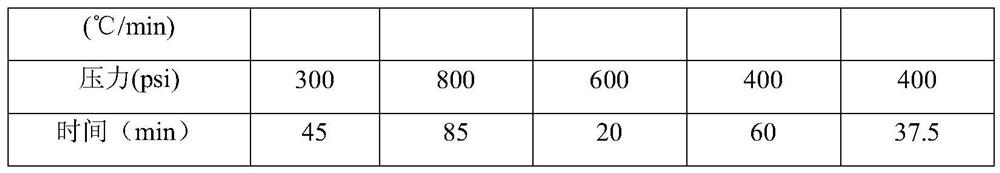

Embodiment 2

[0059] Weigh microwave dielectric ceramic powder (D50 particle size 1-2um, dielectric constant 80): 400g; silica powder: 150g; Daikin concentrated dispersion D210 (solid content 60wt%, particle size: 0.1μm-0.5μm ): 650g; PFA (solid content 60wt%, particle size between 0.1μm-0.5μm): 100g; surfactant (TEGO 755): 80g, distilled water 400ml.

[0060] Microwave dielectric ceramic powder is added to water to form a dispersion; then surfactants and inorganic reinforcing fillers are added; after ball milling, fluororesin dispersion is added and mixed to obtain a stable water-based emulsion. During ball milling, stir in a sand mill at high speed for 60-120 minutes at a speed of 1000r / min until a stable water-based suspension emulsion is formed, and ceramic and filler particles do not agglomerate or settle in the emulsion. Transfer the above aqueous suspoemulsion to a spray drying machine, and undergo high temperature (100°C-120°C) cyclone separation to make powdery particles with a par...

Embodiment 3

[0068] Weigh microwave dielectric ceramic powder (D50 particle size 5um, dielectric constant 100, thermal expansion coefficient not greater than 10ppm / °C): 150g; glass microspheres: 15g; Daikin concentrated dispersion D210 (solid content 60wt%, particle size: 0.1μm-0.5μm): 60g; PFA (solid content 60wt%, particle size between 0.1μm-0.5μm): 10g; surfactant (TEGO 735): 20g, distilled water 180ml.

[0069] The microwave medium ceramic powder is added into water to form a dispersion liquid; then a surfactant and an inorganic reinforcing filler are added; after ball milling, a fluororesin dispersion liquid is added and mixed to obtain a stable water-based emulsion. During ball milling, stir in a sand mill at high speed for 100 minutes at a speed of 1000r / min until a stable aqueous suspension emulsion is formed, and ceramic and filler particles do not agglomerate or settle in the emulsion. Transfer the above aqueous suspoemulsion to a spray drying machine, and undergo high temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com