High-dilution-times aqueous liquid dust suppressant and preparation and use method thereof

A technology of water-based liquid and dust suppressant, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of increased transportation costs, low dilution times, and resistance to rainwater washing, so as to reduce transportation costs and use costs, and prepare The effect of scientific and reasonable technology, good drought resistance and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

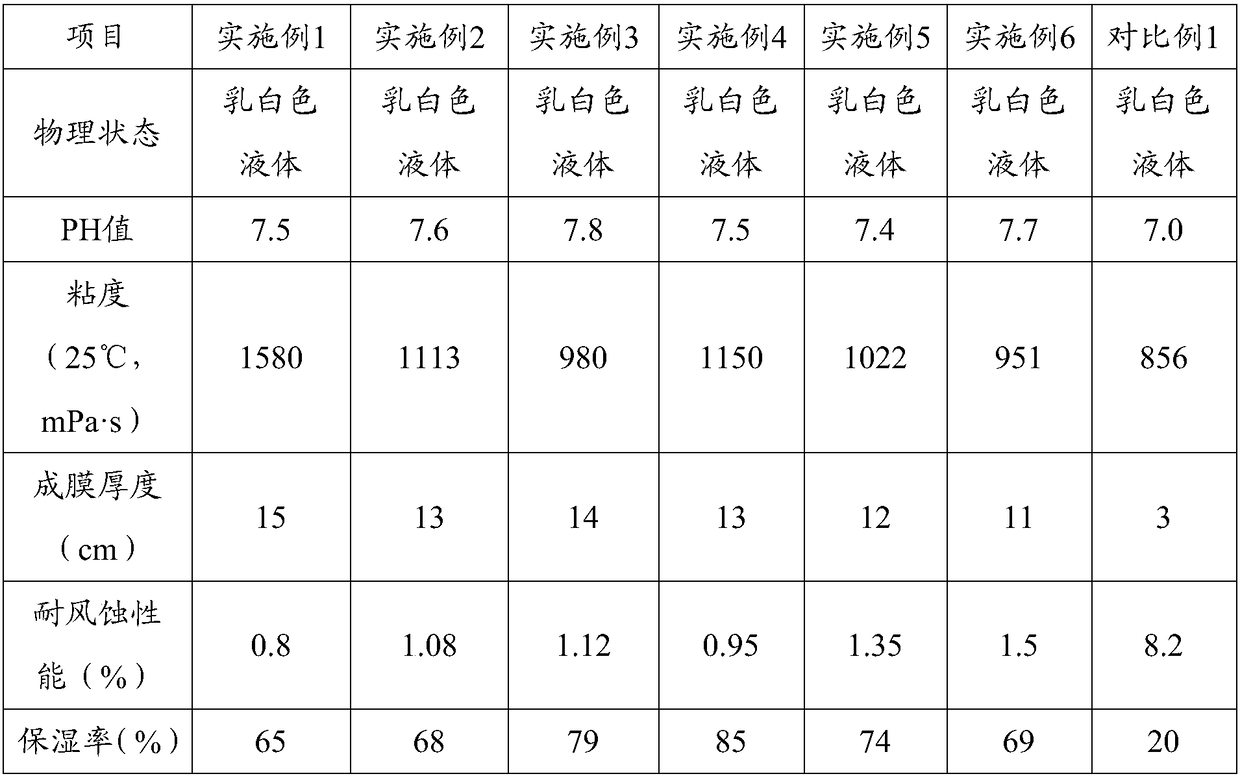

Examples

Embodiment 1

[0050] A water-based liquid dust suppressant with a high dilution ratio, comprising the following components in parts by weight: 35 parts of hyperbranched resin, 0.1 part of polyvinyl alcohol 2488, 2.0 parts of dioctyl maleate sodium sulfonate, 0.5 part of alkyl Phenol polyoxyethylene ether, 3 parts of sodium carboxymethylcellulose, 50 parts of ethylene glycol, 0.4 parts of benzotriazole, 1 part of food coloring agent, 6 parts of titanium nickel yellow.

[0051] The preparation method of above-mentioned hyperbranched resin is:

[0052] The parts by mass are in g, 75g of methyl acrylate, 50g of methoxypolyoxyethylene acrylate (molecular weight: 400), and 36g of pentaerythritol tetraacrylate are mixed in proportion as a raw material mixture for later use. Add 100 g of distilled water to a reactor equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a nitrogen conduit, start stirring, and replace with nitrogen for 15 minutes. When the water bath is hea...

Embodiment 2

[0054] A high dilution ratio water-based liquid dust suppressant, comprising the following components in parts by weight: 40 parts of hyperbranched resin, 3 parts of polyvinyl alcohol 1788, 1.0 part of sodium dodecylbenzenesulfonate, 1.0 part of fatty alcohol polyoxyethylene ether , 1.0 parts of hydroxypropyl methylcellulose, 10 parts of ethylene glycol, 5 parts of ethanol, 3 parts of glycerol, 5.0 parts of boric acid, and 10 parts of red iron oxide.

[0055] The preparation method of above-mentioned hyperbranched resin is:

[0056] The parts by mass are in g, 45g of hydroxyethyl acrylate, 60g of methoxypolyoxyethylene acrylate (molecular weight: 1000), and 17.6g of pentaerythritol tetraacrylate are mixed in proportion to be a raw material mixture for later use. Add 100 g of distilled water to a reactor equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a nitrogen conduit, start stirring, and replace with nitrogen for 15 minutes. When the water ba...

Embodiment 3

[0058] A high dilution factor water-based liquid dust suppressant, comprising the following components in parts by weight: 60 parts of hyperbranched resin, 5 parts of polyvinyl alcohol 2488, 0.2 part of sodium dodecylsulfonate, 1.0 part of fatty alcohol polyoxyethylene ether, 0.5 parts of hydroxyethyl cellulose, 1.0 parts of hydroxypropyl methylcellulose, 10 parts of calcium acetate, 5 parts of magnesium acetate, 5 parts of dipropylene glycol butyl ether, 0.2 parts of benzotriazole, 4.0 parts of boric acid, 5 parts of oxidation iron green.

[0059] The preparation method of above-mentioned hyperbranched resin is:

[0060] The parts by mass are in g, 50g of hydroxypropyl acrylate, 45g of allyl polyoxyethylene ether (molecular weight: 1000), and 14.4g of pentaerythriol tetraacrylate are mixed in proportion to be a raw material mixture for later use. Add 100 g of distilled water to a reactor equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com