High adhesiveness full mold casting coating and preparation method thereof

A technology of solid casting and adhesion, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of poor high temperature resistance of coatings, improve adhesion, prevent carbon deposition, and have simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

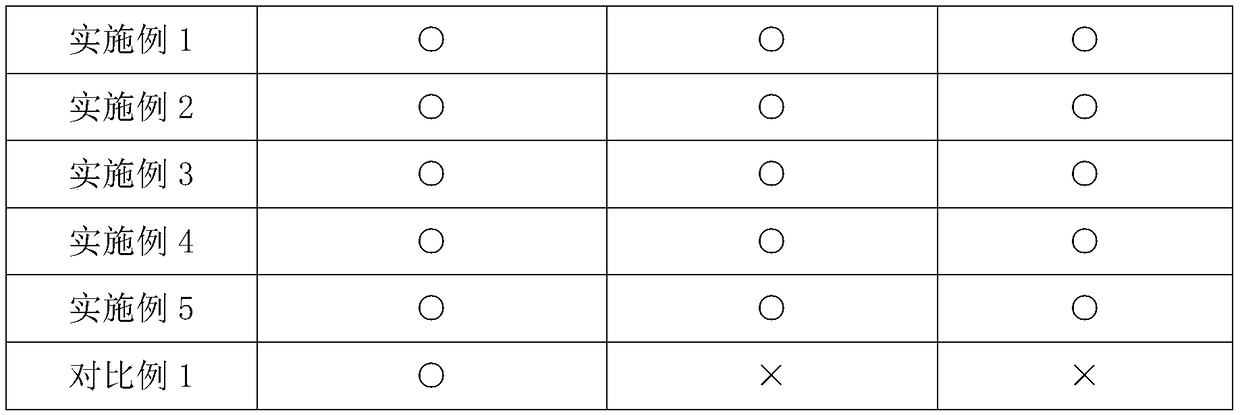

Examples

Embodiment 1

[0030] A high-adhesion solid forging paint, comprising the following raw materials in parts by weight:

[0031] 40 parts of mullite, 5 parts of kyanite, 4 parts of flake graphite, 5 parts of mica, 8 parts of modified bentonite, 3 parts of fused magnesium powder, 1 part of hydroxymethyl cellulose, 2 parts of nano-iron oxide, cryolite 1 part, 4 parts of binder, 0.6 part of surfactant, 0.4 part of defoamer and 0.6 part of preservative.

[0032] The binder is composed of phenolic resin, ethanol and polyvinyl butyral in a mass ratio of 15:250:3.

[0033] The preparation method of modified bentonite is as follows:

[0034] (1) Add calcium-based bentonite to 1.0 mol / liter sodium chloride solution and mix evenly, heat up to 50-60 degrees Celsius, stir and mix at a speed of 400 rpm for 3 hours, leave the suspension for 18 hours, and centrifuge Separation, removal of the supernatant, repeated washing with deionized water 6 times, drying in an oven at 90 degrees Celsius, and grinding t...

Embodiment 2

[0045] A high-adhesion full mold casting paint, comprising the following raw materials in parts by weight:

[0046] 50 parts of mullite, 10 parts of kyanite, 9 parts of flake graphite, 10 parts of mica, 15 parts of modified bentonite, 6 parts of fused magnesium powder, 3 parts of hydroxymethyl cellulose, 5 parts of nano iron oxide, cryolite 3 parts, 7 parts of binder, 1.2 parts of surfactant, 0.8 part of defoamer and 1.2 parts of preservative.

[0047] The binder is composed of phenolic resin, ethanol and polyvinyl butyral in a mass ratio of 15:250:3.

[0048] The preparation method of modified bentonite is as follows:

[0049](1) Add calcium-based bentonite to 1.0 mol / liter sodium chloride solution and mix evenly, heat up to 60 degrees Celsius, stir and mix at a speed of 600 rpm for 3 hours, leave the suspension for 22 hours, and centrifuge, Remove the supernatant, wash it repeatedly 6 times with deionized water, dry it in an oven at 100 degrees Celsius, and grind it throug...

Embodiment 3

[0060] A high-adhesion full mold casting paint, comprising the following raw materials in parts by weight:

[0061] 42 parts of mullite, 6 parts of kyanite, 5 parts of flake graphite, 6 parts of mica, 10 parts of modified bentonite, 4 parts of fused magnesium powder, 1.5 parts of hydroxymethyl cellulose, 3 parts of nano iron oxide, cryolite 1.5 parts, 5 parts of binder, 0.7 part of surfactant, 0.5 part of defoamer and 0.7 part of preservative.

[0062] The binder is composed of phenolic resin, ethanol and polyvinyl butyral in a mass ratio of 15:250:3.

[0063] The preparation method of modified bentonite is as follows:

[0064] (1) Add calcium-based bentonite to 1.0 mol / liter sodium chloride solution and mix evenly, heat up to 55 degrees Celsius, stir and mix at a speed of 500 rpm for 3 hours, leave the suspension for 20 hours, and centrifuge, Remove the supernatant, wash with deionized water repeatedly for 6 times, place in an oven at 95 degrees Celsius to dry, and grind th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com