A strain of Lactobacillus fermentum with high production of ferulic acid esterase and its application

A technology for fermenting lactobacillus and ferulic acid esterase, which is applied in the direction of lactobacillus, application, bacteria used in food preparation, etc., can solve the problems that the output cannot meet the market demand, unfavorable large-scale production, long fermentation time, etc. Achieve the effects of improving quality and protecting the environment, improving utilization rate, and producing acid quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、17

[0050] Isolation and identification of embodiment 1, 17SD-2 bacterial strain

[0051] 1. Isolation of 17SD-2 strain

[0052] 17SD-2 was isolated from fresh corn silage. The specific separation method is as follows: take 10 g of fresh corn silage, add 90 mL of normal saline, and dilute it to 10 -7 , select the appropriate gradient to spread on the MRS medium (1L MRS medium formula is beef extract 10g, casein peptone 10g, yeast extract 5g, glucose 20g, sodium acetate 5g, diamine hydrogen citrate 2g, Tween80 1mL, K 2 HPO 4 2g, MgSO 4 ·7H 2 O 0.58g, MnSO 4 ·7H 2 (0.25g, agar powder 1.5%, distilled water to 1L, autoclaved) or improved MC medium (1L improved MC medium formula is soybean peptone 5g, beef extract powder 3g, yeast extract powder 3g, Glucose 20g, lactose 20g, calcium carbonate 10g, agar powder 1.5%, distilled water to 1L, autoclaved) or BHI brain heart infusion agar medium (1L BHI brain heart infusion agar medium formula is bovine brain Extract powder 12.5g, be...

Embodiment 2

[0057] Embodiment 2, the preparation of microbial preparation 17SD-2

[0058] 1. The 17SD-2 strain isolated and purified in Example 1 was inoculated into MRS liquid medium, and fermented and cultured in a 37° C. incubator for 72 hours to obtain 17SD-2 fermentation broth.

[0059] 2. Centrifuge the 17SD-2 fermentation broth obtained in step 1 for 2-5min at 10000-12000rpm, collect the supernatant to obtain the supernatant of the 17SD-2 fermentation broth (the concentration of the 17SD-2 bacterial strain is 10 14 -10 18 CFU / L). The supernatant of 17SD-2 fermentation broth was named microbial preparation 17SD-2.

Embodiment 3

[0060] Embodiment 3, the application of microbial preparation 17SD-2 in degrading ethyl ferulate

[0061] 1. The supernatant of 17SD-2 fermentation broth degrades ethyl ferulate to produce a transparent circle

[0062] 1. The MRS medium that does not contain glucose is cooled to 50-55 ° C, then ethyl ferulate is added in the medium in an amount of 0.1% (mass fraction), and the plate is inverted to prepare ethyl ferulate as Plates with sole carbon source.

[0063] 2. Use the well-drilling method to drill holes on the plate with the ethyl ferulic acid obtained in step 1 as the only carbon source, and then take 10 μL of the microbial preparation 17SD-2 prepared in Example 2 and add it to the holes. Placed in the medium for 48-72 hours, and physiological saline was used as a negative control.

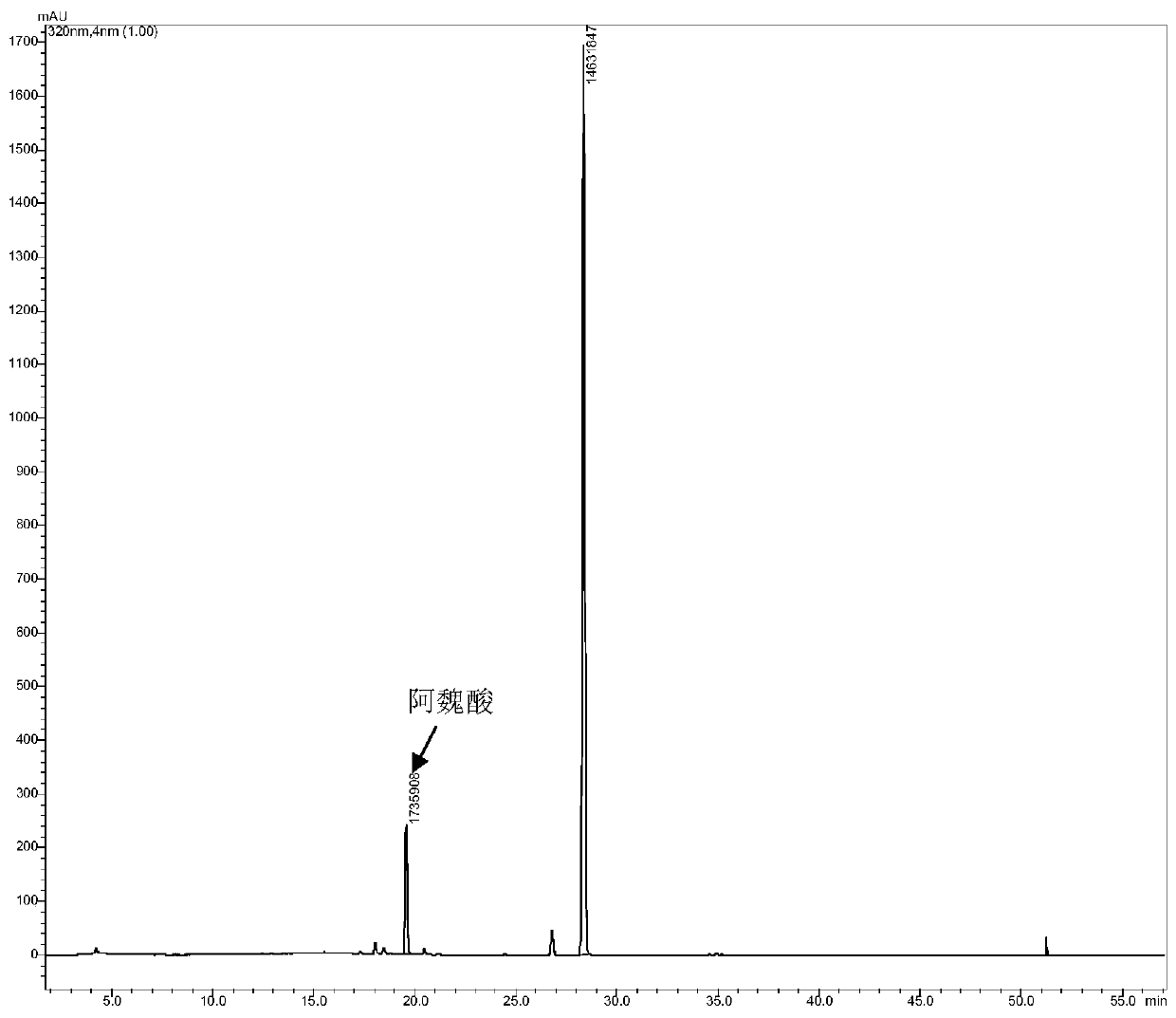

[0064] The result is as figure 1 shown. The results showed that the microbial preparation 17SD-2 could degrade ethyl ferulate and produce a clear transparent circle. It shows that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com