Preparation method of antifouling self-cleaning coating for glass

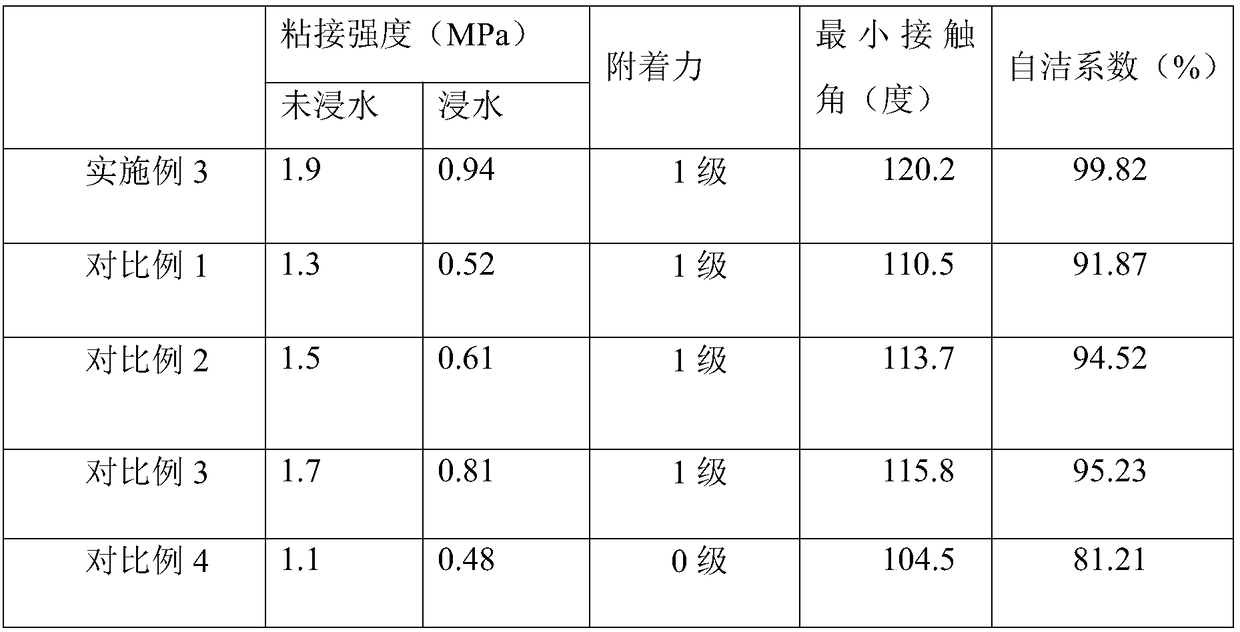

A glass and anti-fouling technology, applied in the field of coatings, can solve the problems of difficult glass use, weak adhesion, poor self-cleaning performance, etc., and achieve the effects of improved self-cleaning coefficient, improved bonding strength after immersion in water, and enhanced dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of the antifouling self-cleaning coating for glass of the present embodiment, comprises the following steps:

[0026] Step 1, weigh the following raw materials in parts by weight: 34 parts of silicone modified epoxy resin, 24 parts of silicon nitrogen resin, 16 parts of modified silica microsphere emulsion, 14 parts of modified volcanic glass, methyl hydroxyethyl fiber 5 parts of prime, 12 parts of solvent, 3 parts of sodium bentonite, 2 parts of coupling agent;

[0027] Step 2: Add the silicone epoxy resin in step 1 into the reaction kettle, then add the silicon nitrogen resin and the modified silica microsphere emulsion, the stirring temperature rises to 155°C, the stirring speed rises to 215r / min, stir The time is 35 minutes, then add modified volcanic glass and continue to stir for 15 minutes, and finally add methyl hydroxyethyl cellulose, solvent, sodium bentonite, coupling agent in turn, and continue to stir for 35 minutes to obtain th...

Embodiment 2

[0036] A kind of preparation method of the antifouling self-cleaning coating for glass of the present embodiment, comprises the following steps:

[0037] Step 1, weigh the following raw materials in parts by weight: 40 parts of silicone modified epoxy resin, 28 parts of silicon nitrogen resin, 22 parts of modified silica microsphere emulsion, 18 parts of modified volcanic glass, methyl hydroxyethyl fiber 9 parts of prime, 18 parts of solvent, 6 parts of sodium bentonite, 5 parts of coupling agent;

[0038] Step 2: Add the silicone epoxy resin in step 1 into the reaction kettle, then add the silicon nitrogen resin and modified silica microsphere emulsion, the stirring temperature rises to 165°C, the stirring speed rises to 225r / min, stir The time is 45 minutes, then add modified volcanic glass and continue to stir for 25 minutes, and finally add methyl hydroxyethyl cellulose, solvent, sodium bentonite, coupling agent in turn, and continue to stir for 45 minutes to obtain the an...

Embodiment 3

[0047] A kind of preparation method of the antifouling self-cleaning coating for glass of the present embodiment, comprises the following steps:

[0048] Step 1, weigh the following raw materials in parts by weight: 37 parts of silicone modified epoxy resin, 26 parts of silicon nitrogen resin, 19 parts of modified silica microsphere emulsion, 16 parts of modified volcanic glass, methyl hydroxyethyl fiber 7 parts of prime, 15 parts of solvent, 4.5 parts of sodium bentonite, 3.5 parts of coupling agent;

[0049] Step 2: Add the silicone epoxy resin in step 1 into the reaction kettle, then add the silicon nitrogen resin and the modified silica microsphere emulsion, raise the stirring temperature to 160°C, raise the stirring speed to 220r / min, and stir The time is 40 minutes, then add modified volcanic glass and continue to stir for 20 minutes, and finally add methyl hydroxyethyl cellulose, solvent, sodium bentonite, coupling agent in turn, and continue to stir for 40 minutes to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com