Flame-retardant shell material for battery car chargers

A shell material and charger technology, applied in the field of flame retardant shell materials for battery car chargers, can solve the problems of poor tear resistance of battery car charger shells, difficulty in fire fighting, escape, life saving, incomplete combustion, etc., and achieve elongation at break Good rate and resistance to permanent compression deformation, good cross-linking degree, and the effect of enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

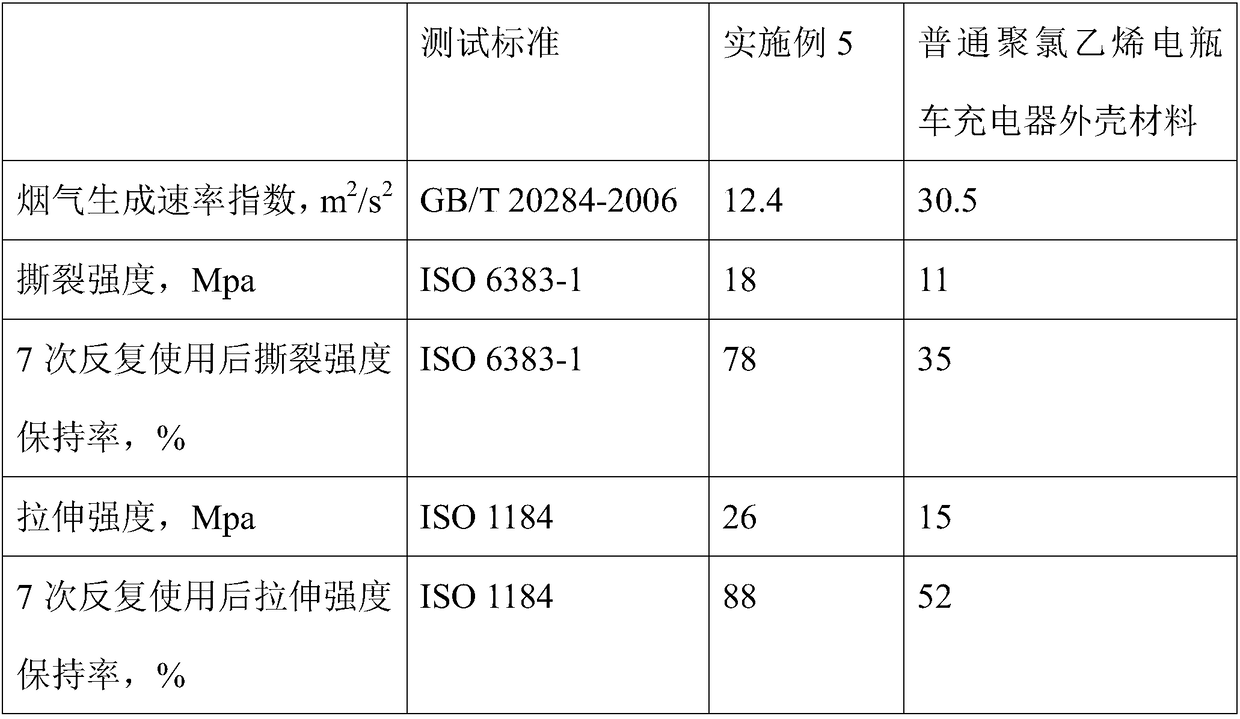

Examples

Embodiment 1

[0014] A flame-retardant shell material for battery car chargers. Its raw materials include: base material 125kg, modified sand artemisia gum 10kg, disproportionated rosin 0.3kg, zinc stearate 2kg, 9,10-epoxy octyl stearate 0.4kg, Coupling agent 2.5kg, magnesium hydroxide 20kg, melamine formaldehyde resin 12kg, white carbon black 8kg, coal gangue 16kg, calcined kaolin 2kg, sepiolite powder 16kg, titanate coupling agent 0.1kg.

[0015] The base material is composed of polyvinyl chloride, neoprene rubber, and methyl phenyl vinyl rubber in a weight ratio of 65:30:54; the crosslinking agent is composed of dicumyl peroxide, 2,4,6-tris(dimethyl The weight ratio of aminomethyl)phenol and zinc methacrylate is 1.2:1:0.1.

[0016] The modified sand wormwood gum is prepared by the following process: stir 15kg sand wormwood gum, 4kg whey protein, 64kg water for 15min, add 8kg polyurethane fiber, 1kg glycerol triglycidyl ether, stir for 10min, fill with nitrogen to saturation, add 0.2kg Potass...

Embodiment 2

[0018] A flame-retardant shell material for battery car chargers. The raw materials include: base material 130kg, modified sand artemisia gum 2kg, disproportionated rosin 1kg, zinc stearate 1kg, 9,10-epoxy octyl stearate 1kg, crosslinking agent 1.5kg, 30kg of magnesium hydroxide, 4kg of melamine formaldehyde resin, 12kg of white carbon black, 10kg of coal gangue, 8kg of calcined kaolin, 10kg of sepiolite powder, 0.6kg of titanate coupling agent.

[0019] The base material is composed of polyvinyl chloride, neoprene rubber, and methyl phenyl vinyl rubber in a weight ratio of 45:38:24; the crosslinking agent is composed of dicumyl peroxide, 2,4,6-tris(dimethyl The weight ratio of aminomethyl)phenol and zinc methacrylate is 2:0.2:0.2.

[0020] The modified sand wormwood gum is prepared by the following process: stir 10kg sand wormwood gum, 8kg whey protein, 42kg water for 23min, add 4kg polyurethane fiber, 2kg glycerol triglycidyl ether, stir for 2min, fill with nitrogen to saturation...

Embodiment 3

[0022] A flame-retardant shell material for battery car chargers. The raw materials include: base material 127kg, modified sand artemisia gum 8kg, disproportionated rosin 0.5kg, zinc stearate 1.8kg, 9,10-epoxy octyl stearate 0.6kg, Crosslinking agent 2.2kg, magnesium hydroxide 22kg, melamine formaldehyde resin 10kg, white carbon black 9kg, coal gangue 14kg, calcined kaolin 4kg, sepiolite powder 14kg, titanate coupling agent 0.2kg.

[0023] The base material is composed of polyvinyl chloride, neoprene rubber, and methyl phenyl vinyl rubber in a weight ratio of 60:32:50; the crosslinking agent is composed of dicumyl peroxide, 2,4,6-tris(dimethyl The weight ratio of aminomethyl)phenol and zinc methacrylate is 1.4:0.8:0.12.

[0024] The modified sand wormwood gum is prepared by the following process: stir 14kg sand wormwood gum, 5kg whey protein, 60kg water for 18min, add 7kg polyurethane fiber, 1.2kg glycerol triglycidyl ether and stir for 8min, fill with nitrogen to saturation, add 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com