Method for producing 1,5-pentanediamine by fermenting soybean residue hydrolysate

A technology of hydrolyzed liquid and pentamethylenediamine is applied in the field of fermenting and producing 1,5-pentamethylenediamine by using bean dregs hydrolyzed liquid, which can solve the problem of low utilization rate of bean curd dregs, and achieve the advantages of abundant output, lower production cost and good development prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 constructs recombinant escherichia coli

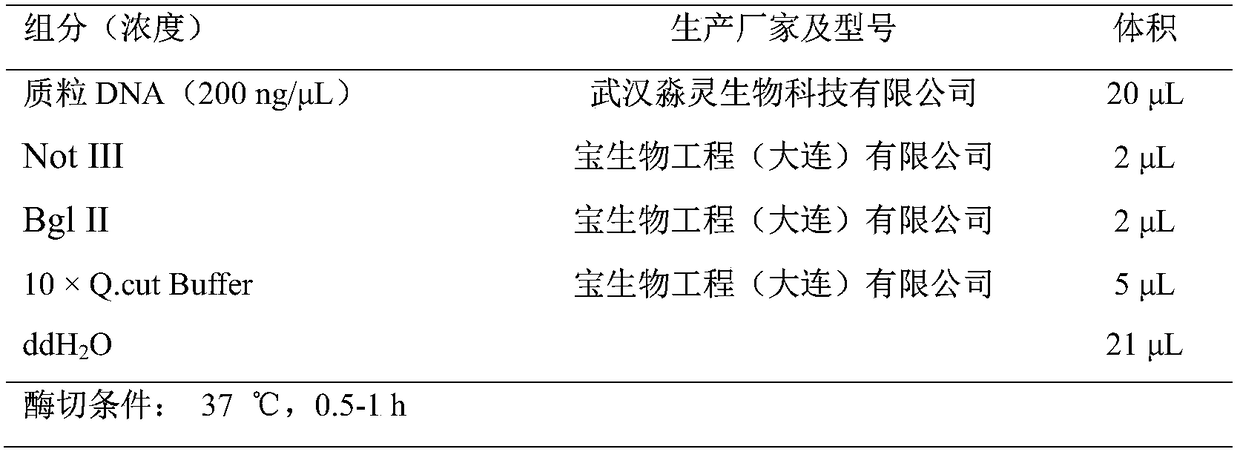

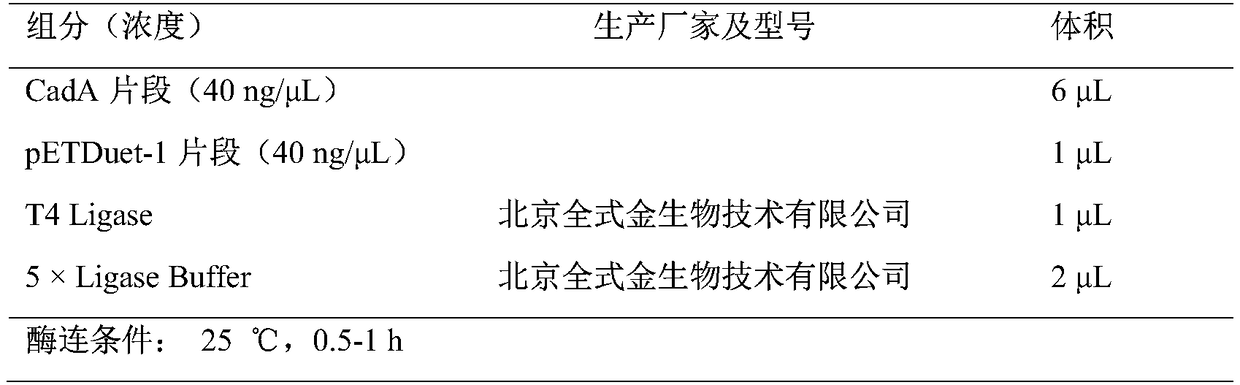

[0020] (1) Construction of recombinant plasmid pCDFduet-CadA: The lysine decarboxylase gene CadA derived from Escherichia coli MG1655 (purchased from Wuhan Miaoling Biotechnology Co., Ltd.) was obtained from the plasmid mini-extraction kit (TianGen). The target fragment CadA is obtained by digestion at the Not III and Bgl II restriction sites, and its nucleotide sequence is shown in SEQ ID No:1. The nucleic acid gel was verified and proved to be the target band, and the target gene was recovered through the gel recovery kit (TianGen). Digest the plasmid pCDFduet (restriction sites are Not III and Bgl II), see Table 1; use T4 DNA ligase to connect the target fragment CadA with the digested plasmid pCDFduet to obtain the recombinant plasmid pCDFduet-CadA, see Table 2 , the resistance of the recombinant plasmid is streptavidin, the promoter of CadA is Trc, and the stop codon is rrnB.

Embodiment 2

[0027] Example 2 Production of 1,5-pentanediamine by fermenting soybean dregs hydrolyzate

[0028](1) Mix wet bean dregs (10g) and water (120mL) at room temperature according to a mass ratio of 1:12, and adjust the pH to 7.0. Pour the mixture into a three-necked flask and place it on a temperature-controlled magnetic stirrer. When the temperature reaches 55°C, add alkaline protease and cellulase at the same time, the dosage of alkaline protease is 1.5g / 100mL mixed solution, the dosage of cellulase is 1.5g / 100mL mixed solution, and the enzyme activity of alkaline protease is 200U / mg, cellulase activity is 10000U / g. Control the temperature at 55° C., 300 rpm, and react for 4 hours. After the hydrolysis was completed, the enzyme was inactivated and the reaction was terminated, and the hydrolyzed solution was obtained by centrifuging at 8000r / min for 10 minutes. The hydrolyzed solution mainly contained reducing sugar and organic nitrogen with concentrations of 12g / L and 2g / L res...

Embodiment 3

[0032] Example 3 Production of 1,5-pentanediamine by fermenting soybean dregs hydrolyzate

[0033] (1) Place the bean dregs in an oven to dry overnight, and then pulverize them with a pulverizer to obtain bean dregs powder. Mix okara powder (50g) and water (1000mL) at a mass ratio of 1:20, adjust the pH to 11 with 1mol / L NaOH aqueous solution, pour the mixture into a three-necked flask and place it on a temperature-controlled magnetic stirrer , 65°C, 300rpm for 1h. Adjust the pH of the mixed solution after alkali treatment to 6.0 with glacial acetic acid, add neutral protease with a volume of 0.4% of the mixed solution (ie 0.4g / 100mL mixed solution, the same below), the enzyme activity is 8000U / g, 55°C, 300rpm Under the condition of reaction 1h. After the reaction, the temperature was raised to 90°C, and the enzyme was inactivated for 20 minutes. After cooling to room temperature, suction filtration, the hydrolyzate contains organic nitrogen, the content is 10g / L.

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com