Supercapacitor and production method thereof

A technology of supercapacitor and copper sulfide, applied in the field of capacitors, can solve the problems of low electronegativity, low ionic conductivity, and needs to be studied, and achieve the effect of improving electrochemical performance, good structural flexibility, and improving window voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

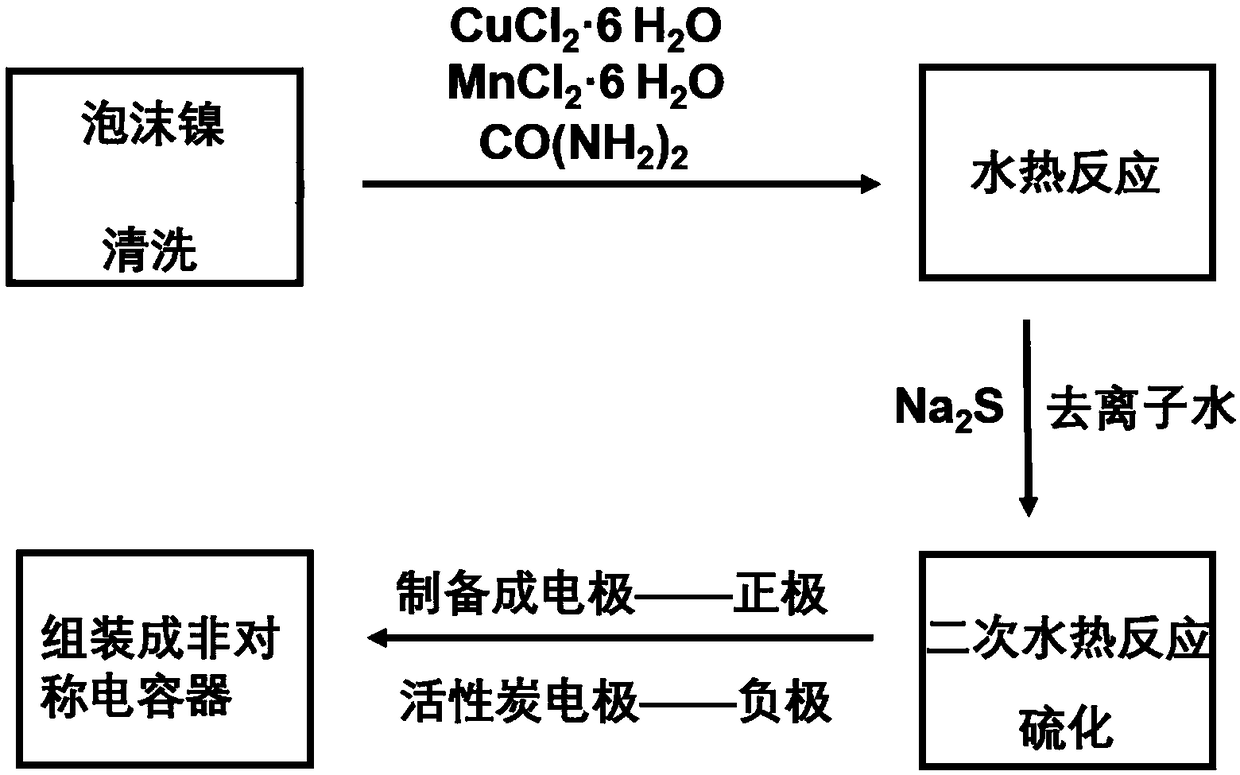

[0043] Box flow such as figure 1 shown; the diagrammatic process is as follows Figure 4 shown;

[0044] The nickel foam is surface treated to remove oil and impurities to obtain a nickel foam matrix;

[0045] CO(NH 2 ) 2 , CuCl 2 ·6H 2 O and MnCl 2 ·6H 2 O dissolved in water to make a mixed solution; CuCl 2 The concentration is 0.004M, CuCl 2 with MnCl 2 The molar ratio is 1:2, CuCl 2 with CO(NH 2 ) 2 The molar ratio is 1:20; the nickel foam matrix is placed in the hydrothermal reaction kettle, and then the mixed solution is put into the hydrothermal reaction kettle to immerse the nickel foam substrate; the hydrothermal reaction kettle is closed and placed in an oven, at 180 Insulate at ±10°C for 6 hours to perform a hydrothermal reaction; then take out the hydrothermal reaction vessel and cool it to room temperature, then take out the foamed nickel substrate loaded with the precursor, rinse with alcohol and water to remove surface impurities, and finally place...

Embodiment 2

[0050] Method is with embodiment 1, and difference is:

[0051] (1) CuCl 2 with MnCl 2 The molar ratio is 1:2.5, CuCl 2 with CO(NH 2 ) 2 The molar ratio is 1:15;

[0052] (2) A hydrothermal reaction is kept for 7 hours, and after cleaning, it is kept in an oven for 5 hours; the density difference between the loaded nickel substrate and the foamed nickel substrate is 1.1mg / cm 3 ;

[0053] (3) The secondary hydrothermal reaction is kept for 5 hours, and after cleaning, it is placed in an oven at 50±5°C for 5 hours.

Embodiment 3

[0055] Method is with embodiment 1, and difference is:

[0056] (1) CuCl 2 with MnCl 2 The molar ratio is 1:3, CuCl 2 with CO(NH 2 ) 2 The molar ratio is 1:10;

[0057](2) A hydrothermal reaction is kept for 8 hours, and after cleaning, it is kept in an oven for 4 hours; the density difference between the loaded nickel substrate and the foamed nickel substrate is 1.2mg / cm 3 ;

[0058] (3) The secondary hydrothermal reaction is kept for 4 hours, and after cleaning, it is placed in an oven at 50±5°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com