Environmental protection stainless steel workpiece passivation process

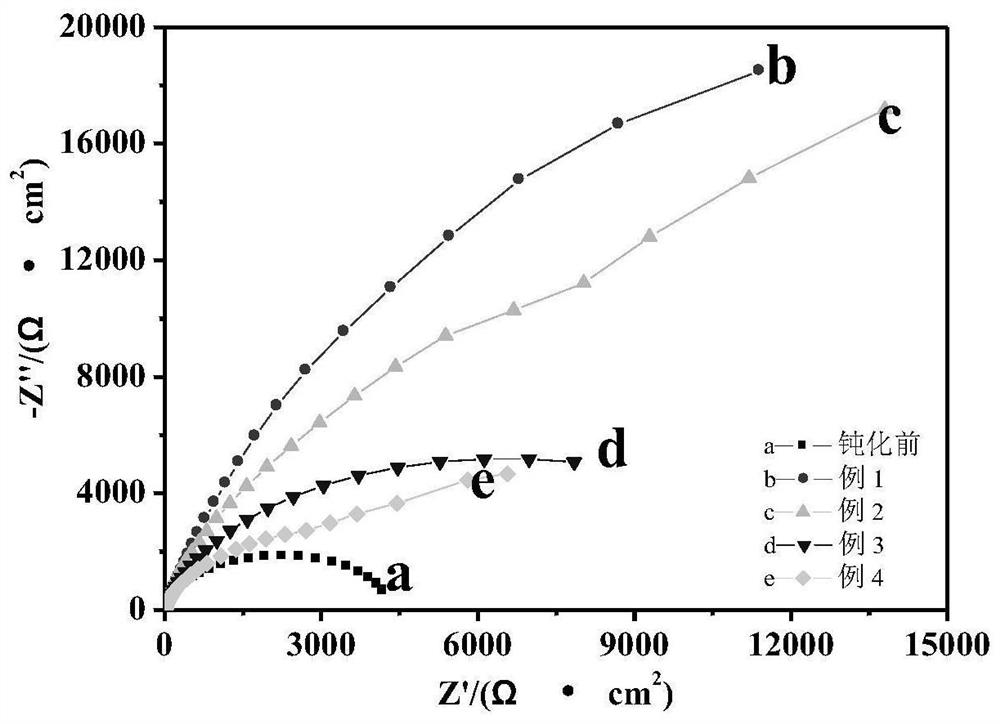

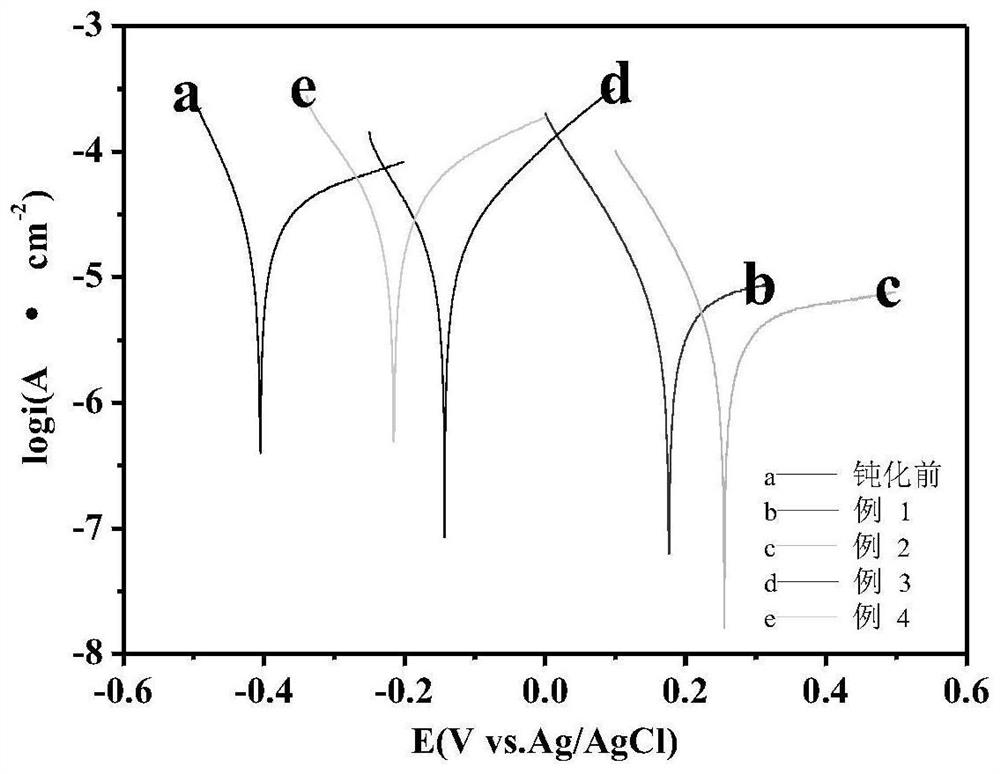

A technology for stainless steel and workpieces, which is applied in the coating process of metal materials, etc., can solve the problems of endangering the physical safety of operators in the environment, and cannot meet the requirements of non-toxic and harmless, and achieve the effects of reducing self-corrosion current, compact structure, and improving rust prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

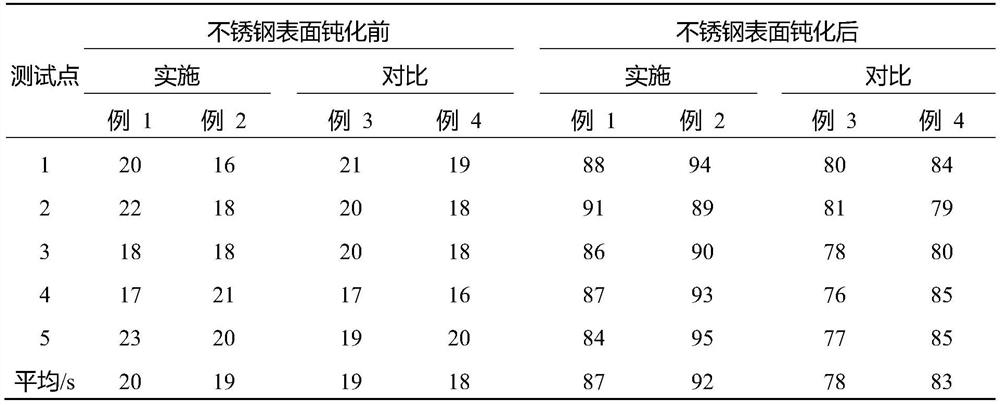

Examples

Embodiment 2

[0070]Ethylenediamine di-o-hydroxyl sodium ferric acetate 5g / L, triphenyl ring imidazoline quaternary ammonium salt 4g / L, polyhydroxy polymer organic sodium salt 3g / L, phytic acid 8ml / L, hydroxyethylidene diphosphate 4g / L, ethylenediaminetetraacetic acid 4g / L, sodium molybdate 20g / L, sodium tungstate 12g / L, lanthanum nitrate 2g / L, zirconium nitrate 0.5g / L, potassium hexafluorozirconate 2g / L, benzotriazole Azazole 2g / L, polyvinyl alcohol 8g / L, polyacrylic acid 2ml / L, alkylphenol polyoxyethylene ether (TX-10) 1g / L, fatty alcohol polyoxyethylene ether (JFC) 2ml / L, hydroxylamine sulfate (HAS) 1g / L, water-soluble imidazoline 2ml / L, aniline 2g / L, cerium sulfate 1g / L, titanium nitrate 1g / L, quaternary ammonium salt 2g / L, sodium tetrapropylene benzene sulfonate 4g / L, organic amine resin (TPP) 1g / L, organic carboxylic acid sodium salt 6g / L, fluoride additives (sodium fluoride 4g / L and sodium fluoroborate 3g / L, lithium hexafluorophosphate 2g / L), polyoxyethylene alkyl Phenyl ether 0.5g / L, 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com