Preparation method of manganese doped zinc sulfide quantum dot embedded fluorescent composite membrane

A technology of manganese-doped zinc sulfide and quantum dots, which is applied in the field of quantum dots and membrane materials, can solve the problems that have not been involved in the preparation method, and achieve good effects of low biological toxicity, strong self-cleaning ability, and stable fluorescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

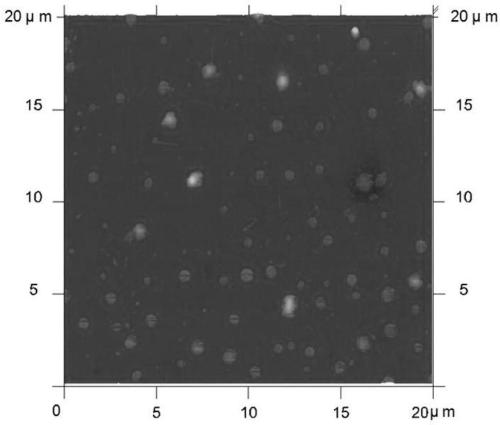

[0025] Preparation of fluorescent composite film embedded with manganese-doped zinc sulfide quantum dots:

[0026] (1) Cut the cleaned silicon wafer into 1cm wide × 3cm long, and use piranha solution (mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide, volume ratio 7:3) to remove surface impurities, and then use pure water and ethanol Cleaned and dried with nitrogen gas;

[0027] (2) Cut the polymethyl methacrylate (PMMA) film into a size of 0.75cm wide × 1.0cm, clean the cut PMMA film, blow dry with nitrogen, and then cover the PMMA film on the processed silicon wafer, clip clamp spare;

[0028] (3) The film-forming monomer, cross-linking agent, quantum dots (ZnS: Mn 2+ QDs) were dissolved in a certain amount of solvent, ultrasonically dispersed for 5 minutes, fully mixed and stirred and reacted for 1.0 hour to obtain a casting solution. Described film-forming monomer is acrylic acid (0.60mmol), methacrylic acid (0.20mmol), acrylamide (0.10mmol), an...

Embodiment 2

[0033] Preparation of fluorescent composite film embedded with manganese-doped zinc sulfide quantum dots:

[0034] (1) Cut the cleaned silicon wafer into 0.75cm wide × 2.5cm long, and use piranha solution (mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide, volume ratio 7:3) to remove surface impurities, and then use pure water Clean with ethanol and dry with nitrogen gas;

[0035] (2) Cut the polymethyl methacrylate (PMMA) film into a size of 0.75cm wide × 0.5cm, clean the cut PMMA film, blow dry with nitrogen, and then cover the PMMA film on the processed silicon wafer, clip clamp spare;

[0036] (3) The film-forming monomer, cross-linking agent, quantum dots (ZnS: Mn 2+ QDs) were dissolved in a certain amount of solvent, ultrasonically dispersed for 5 minutes, fully mixed and stirred and reacted for 1.0 hour to obtain a casting solution. The functional monomer is acrylic acid (0.45mmol), methacrylic acid (0.30mmol), acrylamide (0.15mmol), the cros...

Embodiment 3

[0041] Preparation of fluorescent composite film embedded with manganese-doped zinc sulfide quantum dots:

[0042] (1) Cut the cleaned silicon wafer into 0.8cm wide × 3.0cm long, and use piranha solution (mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide, volume ratio 7:3) to remove surface impurities, and then use pure water Clean with ethanol and dry with nitrogen gas;

[0043] (2) Cut the polymethyl methacrylate (PMMA) film into a size of 0.75cm wide × 0.5cm, clean the cut PMMA film, blow dry with nitrogen, and then cover the PMMA film on the processed silicon wafer, clip clamp spare;

[0044] (3) The film-forming monomer, cross-linking agent, quantum dots (ZnS: Mn 2+ QDs) were dissolved in a certain amount of solvent, ultrasonically dispersed for 5 minutes, fully mixed and stirred and reacted for 1.0 hour to obtain a casting solution. The functional monomer is acrylic acid (0.60mmol), methacrylic acid (0.20mmol), acrylamide (0.00mmol), the cross...

PUM

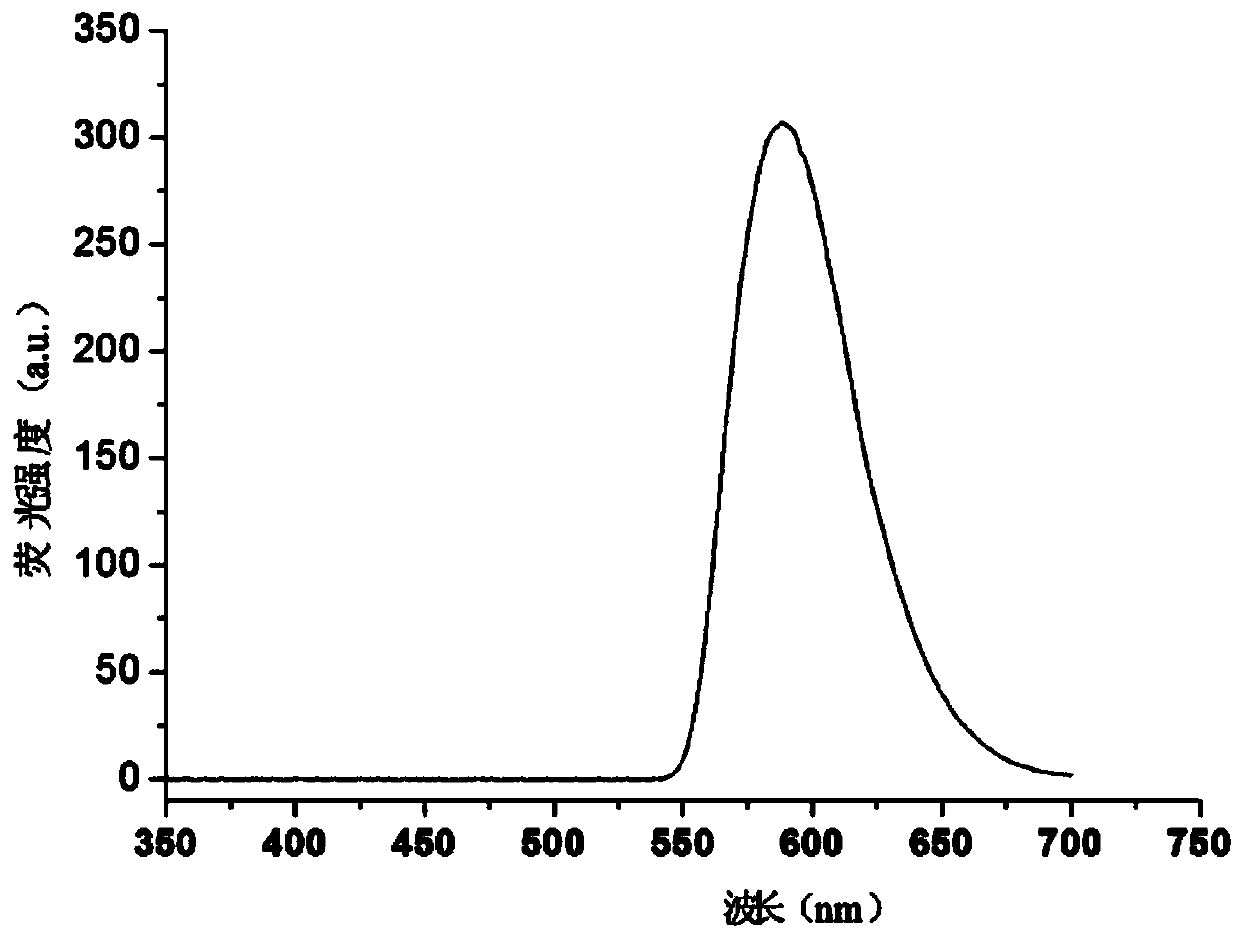

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com