Antibiotic-free feed additive for regulating intestinal stress reaction and preparation method of antibiotic-free feed additive

A technology of stress response and intestinal tract, which is applied in the forming or processing of animal feed, animal feed, application, etc., can solve the problems of weak effect, high cost of use, and large amount of use, so as to relieve intestinal stress response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

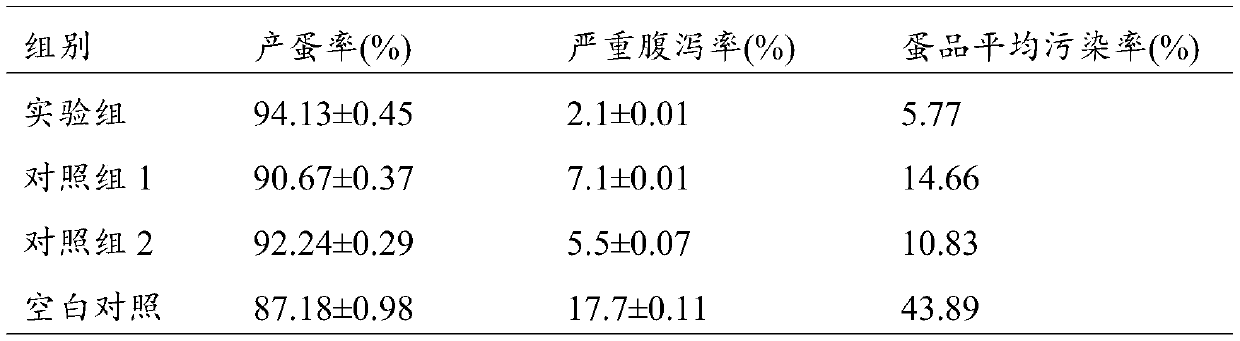

Examples

preparation example 1

[0079] Preparation of Gallic Tannin-Phospholipid / Betaine Complex

[0080] (1) Weigh an appropriate amount of purified gallic tannin 1kg, place it in a 20L solvent composed of equal volume ratio mixed absolute ethanol and sodium dihydrogen phosphate buffer (pH 6.8), stir and dissolve at room temperature, and prepare gallic tannin- Phosphate organic buffer solution.

[0081] (2) Weigh 480g of soybean lecithin and betaine according to the mass ratio of 2:1 and mix them, then add them to 2.5L of absolute ethanol, heat to 35°C, stir and dissolve fully, then pour the above Galla tannin-phosphate organic buffer solution, stir well.

[0082] (3) In a reaction kettle with condensing reflux, heat the above-mentioned reaction raw materials to a temperature of 60° C., magnetically stir the reaction for 1 h, then cool down to 5° C., let it stand for precipitation, filter the precipitated precipitate, and dry it to obtain the following: tannin-betaine complex-based complex component 1; ne...

preparation example 2

[0086] Preparation of enteric-coated granules containing tannin complex

[0087] (1) Take 1000 g of the above-prepared Galla tannin-phospholipid / betaine complex granule, 300 g of tributyrin, and 50 g of nano-zinc oxide, and mix them uniformly to obtain mixture 1; additional auxiliary materials: 200 g of cornstarch, mannose 150g of polysaccharide, 120g of microcrystalline cellulose, 60g of dextrin, 50g of calcium stearate, 20g of sodium carboxymethyl cellulose, 5g of polyvinylpolypyrrolidone, mix the above-mentioned auxiliary materials with mixture 1 in the mixer, and Add 120g of monoglyceride laurate at 65°C, stir at a speed of 80r / min for 15min, then add purified water and stir to form a wet granule soft material, and put the wet soft material into the swing granulator with a pore size of 60-80 mesh Squeeze out the material, put the material into a spheronizer for 15 minutes, and dry it in an oven for 2 hours to obtain core material particles.

[0088] (2) Preparation of ent...

preparation example 3

[0092] Preparation of betaine-sodium n-butyrate granules treated with anti-hygroscopic coating

[0093] (1) Mix 30 g of feed grade betaine hydrochloride, 100 g of whey protein powder, 5 g of sodium n-butyrate and 15 g of amino acids including equal weight methionine and lysine; add 180 g of corn starch, 40 g of beta -Cyclodextrin, and 18g microcrystalline cellulose, stir evenly, use 1wt% hydroxymethylcellulose sodium solution instead of purified water to prepare soft materials, make uniform granules in the granulator, and control the air intake of the granulator The temperature is 50-55°C, the particle size is controlled to be about 60 mesh, and the obtained product is dried;

[0094] (2) to the cellulose acetate ethanol solution of phthalate of 2wt% to the spraying mass fraction of gained granule product to carry out coating treatment (solution consumption is 5wt% of granule product); 2%, so as to obtain about 0.4 kg of betaine-n-butyric acid sodium salt granules treated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com