Efficient fabric carrier

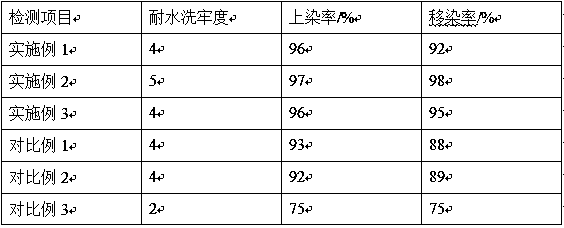

A dye-introducing agent and fabric technology, which is applied in the field of high-efficiency fabric dye-introducing agents, can solve the problems of low washing fastness and large dye migration, and achieve the effects of prolonging the action time and effect, improving the absorption effect, and improving the contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of dye-introducing material A: at 60-75°C, take polyether diol, dimethylol propionic acid, diethylene glycol, active Mix the agent, keep stirring at 400~700r / min for 30~55min, get the reaction material, take the reaction material according to the mass ratio of 20~40:3:6~10, add 4,4-dihydroxydiphenylpropane, N-methyl diphenylpropane Mix ethanolamine, stir and mix at 30~45°C for 25~50min to obtain a mixture, take the mixture at a mass ratio of 30~50:3~7, add acetone and stir to obtain a mixture, and at 30~45°C, take the mixture by Add a sealing agent at a mass ratio of 30~50:1, adjust the pH to 6.4~7.1 with a citric acid solution with a mass fraction of 20%, keep stirring for 30~55min, and naturally cool to room temperature to obtain a cooling product. Take the cooling product at a mass ratio of 30~ 50:20~30:1 Add water and adipic acid dihydrazide to mix, stir and mix at 25~35°C for 40~60min, discharge the material, and then get dyeing agent A.

[0030] The p...

Embodiment 1

[0035] Sealing agent: Mix methyl ethyl ketone oxime and dimethyl ketone oxime at a mass ratio of 1:3 to obtain a sealing agent.

[0036] Active agent: Mix stannous octoate and dibutyltin dilaurate at a mass ratio of 1:2 to obtain the active agent.

[0037] Additive: Mix dextran, lecithin, and guar gum at a mass ratio of 4:1:1 to obtain the additive.

[0038] Excipients: Mix alkyl glucoside, microcrystalline paraffin, and sodium sulfide at a mass ratio of 3:1:0.1 to obtain the excipients.

[0039] Stabilizing agent: at 30°C, mix additives and isopropanol at a mass ratio of 1:15, and stir at 400r / min for 30 minutes to obtain a mixed solution. In parts by mass, take 30 parts of the mixed solution, 0.5 parts of sodium hydroxide, 2 Parts of 3-chloro-2-hydroxypropyl-trimethylammonium chloride and 3 parts of 2, 3-epoxypropyltrimethylammonium chloride were mixed and stirred in a reaction kettle, heated to 70°C, kept for 1 hour, filtered, Wash the filter cake twice with water, move t...

Embodiment 2

[0048] Sealing agent: Mix methyl ethyl ketone oxime and dimethyl ketone oxime at a mass ratio of 1:7 to obtain a sealing agent.

[0049] Active agent: Mix stannous octoate and dibutyltin dilaurate at a mass ratio of 1:4 to obtain the active agent.

[0050] Additive: Mix dextran, lecithin, and guar gum at a mass ratio of 8:1:1 to obtain the additive.

[0051] Excipients: Alkyl glucoside, microcrystalline paraffin, and sodium sulfide are mixed according to the mass ratio of 6:1:0.3 to obtain the excipients.

[0052] Stabilizing agent: at 40°C, mix additives and isopropanol at a mass ratio of 1:30, and stir at 600r / min for 45 minutes to obtain a mixed solution. In parts by mass, take 50 parts of the mixed solution, 1.5 parts of sodium hydroxide, 5 Parts of 3-chloro-2-hydroxypropyl-trimethylammonium chloride and 6 parts of 2,3-epoxypropyltrimethylammonium chloride were mixed and stirred in a reaction kettle, heated to 80°C, kept for 3 hours, filtered, Take the filter cake and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com