A temperature-sensitive chelating adsorption resin, its preparation method, and its method for treating waste water

A temperature-sensitive, chelating adsorption technology, used in adsorption water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. The effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

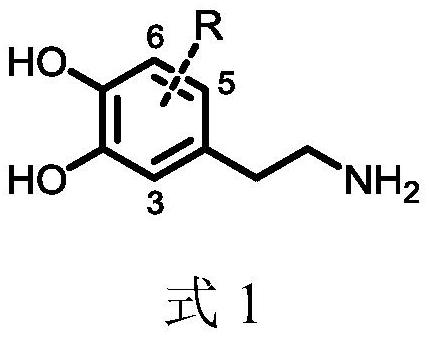

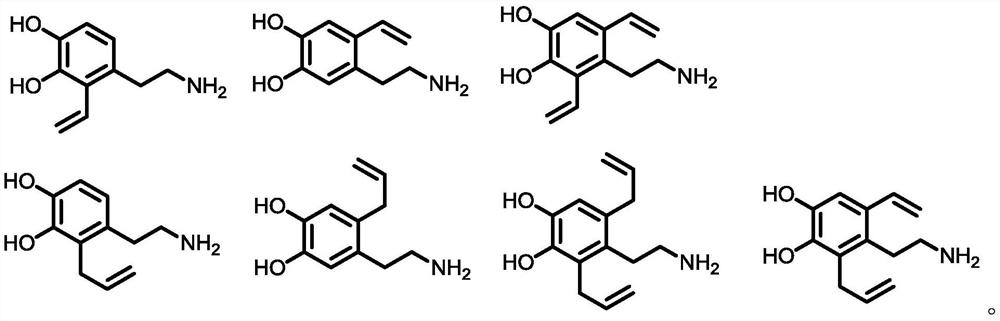

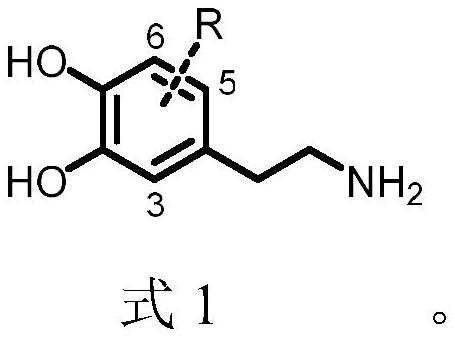

Method used

Image

Examples

Embodiment 1

[0058] At room temperature, a premixed water phase was added, and the composition was 292.3 g of deionized water, 9.0 g of sodium chloride, 0.2 g of polyvinyl alcohol, and 0.3 mg of methylene blue. Add the premixed oil phase, and the composition is 40g of divinylbenzene, 10g of ethylstyrene, 25.0g of toluene, 25.0g of 3# white oil, and 0.5g of benzoyl peroxide. Start stirring, raise the temperature to 85°C, keep the temperature constant for 6 hours, wash with water, extract the porogen, and dry to obtain porous white balls containing suspended double bonds, with a particle size distribution of 400-1200μm and a specific surface area of 750m 2 / g, the average pore diameter is 7.0nm, and the pore volume is 1.3mL / g.

[0059]Take the above 50.0 g of porous white balls containing pendant double bonds and place them in 150 mL of tetrahydrofuran, add 15.0 g of N-isopropylacrylamide, 15.0 g of 3-ethylene-dopamine, and 0.8 g of azobisisobutyronitrile, and replace by bubbling with nitr...

Embodiment 2

[0073] At room temperature, the premixed water phase was added, and the composition was 654.3 g of deionized water, 73.1 g of sodium chloride, 3.6 g of gelatin, and 7.3 mg of methylene blue. Add the premixed oil phase, and the composition is 50.0 g of trivinylbenzene, 40.9 g of styrene, 136.4 g of xylene, 136.4 g of 200# solvent naphtha, and 1.8 g of azobisisobutyronitrile. Start stirring, raise the temperature to 65°C, keep the temperature for 12 hours, wash with water, extract the porogen, and dry to obtain porous white balls containing suspended double bonds, with a particle size distribution of 200-800 μm and a specific surface area of 800 m 2 / g, the average pore diameter is 4.0nm, and the pore volume is 2mL / g.

[0074] Take the above 50.0 g of porous white balls containing dangling double bonds and place them in 500 mL of N,N-dimethylformamide, add 40.0 g of N-n-propyl acrylamide, 5.0 g of 3,5-divinyl-dopamine, peroxide Dibenzoyl 4.8g, argon gas bubbling for 20min to ...

Embodiment 3

[0077] At room temperature, the premixed water phase was added, and the composition was 473.0 g of deionized water, 4.8 g of sodium chloride, 47.8 mg of hydroxypropyl methylcellulose, and 0.05 mg of methylene blue. Add the premixed oil phase, and the composition is 50.0 g of divinyltoluene, 21.4 g of chlorinated styrene, 11.9 g of ethylbenzene, 11.9 g of C20 alkanes, and 0.36 g of dibenzoyl peroxide. Start stirring, raise the temperature to 95°C, keep the temperature constant for 4 hours, wash with water, extract the porogen, and dry to obtain porous white balls containing suspended double bonds, with a particle size distribution of 600-2000 μm and a specific surface area of 200m 2 / g, the average pore diameter is 40.0nm, and the pore volume is 0.3mL / g.

[0078] Take the above 50.0g porous white balls containing pendant double bonds and place them in 50mL of nitrobenzene, add 5.0g of N,N-diethylacrylamide, 40.0g of 5-ethylene-dopamine, and 0.1g of tert-butyl peroxypivalate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com