Negative pole sheet, preparation method thereof, lithium ion battery, preparation method of lithium ion battery and application of lithium ion battery

A negative electrode and negative electrode technology, applied in the field of negative electrode and its preparation, can solve the problems of unknown fast charging effect, harsh raw material requirements, material structure collapse, etc., and achieve the effect of fast charging energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

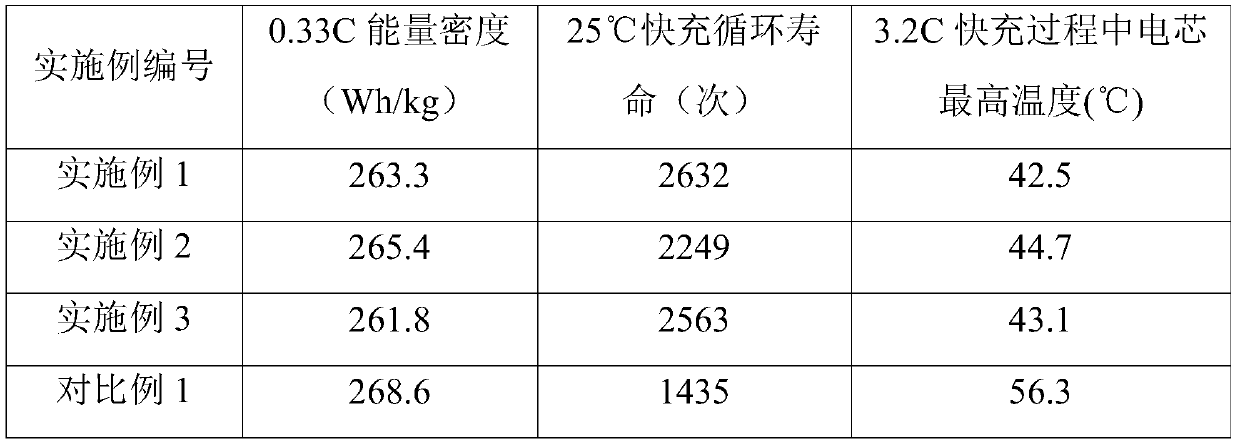

Examples

Embodiment approach

[0050] According to a preferred embodiment of the present invention, the positive electrode tab is an aluminum tab; the negative electrode tab is a nickel-plated copper tab.

[0051] According to a preferred embodiment of the present invention, the separator is a PP film, a PE film, a PP-PE double-layer film or a PP-PE-PP three-layer film.

[0052] According to a preferred embodiment of the present invention, the electrolyte is a mixed solution containing lithium salts, additives and organic solvents.

[0053] According to a preferred embodiment of the present invention, the lithium salt concentration in the mixed solution is 0.8-1.2 mol / L, and the weight percentage of the additive is 0.5-4%.

[0054] According to a preferred embodiment of the present invention, the lithium salt is lithium hexafluorophosphate and / or lithium bis(fluorosulfonyl)imide.

[0055] According to a preferred embodiment of the present invention, the organic solvent is one or more of ethylene carbonate,...

Embodiment 1

[0069] Positive electrode sheet preparation: the positive electrode active material, conductive agent, binder, dispersing aid and solvent are made into a positive electrode slurry in a certain proportion, and in the dry powder of the positive electrode slurry, the ratio of the positive electrode active material is: 97.7 %, conductive agent 1%, binder 1.1%, dispersing aid 0.1%; the prepared positive electrode slurry is evenly coated on both sides of the aluminum foil, and the coating surface density is controlled at 2.5g / 100cm 2 , after drying, rolling, and punching to obtain the positive electrode sheet, the compaction of the rolling is controlled at 3.0 g / cc. The positive electrode active material is: a mixture of NCM811 and NCA (weight ratio is 1:1), and its particle size D50 range is 7.5 μm; the conductive agent is carbon black; the binder is PVDF; the dispersion aid For polyvinylpyrrolidone.

[0070] Negative sheet preparation:

[0071] The first negative electrode activ...

Embodiment 2

[0079] Positive electrode sheet preparation: the positive electrode active material, conductive agent, binder, dispersing aid and solvent are made into a positive electrode slurry in a certain proportion, and in the dry powder of the positive electrode slurry, the ratio of the positive electrode active material is: 96% by mass. %, conductive agent 2.5%, binder 1.4%, dispersing aid 0.1%; the prepared positive electrode slurry is evenly coated on both sides of the aluminum foil, and the coating surface density is controlled at 3g / 100cm 2 , after drying, rolling, and punching to obtain the positive electrode sheet, the compaction of the rolling is controlled at 3.5g / cc. The positive electrode active material is: NCM811, whose particle size D50 is in the range of 8.5 μm; the conductive agent is gas-phase generated carbon fiber; the binder is PTEF; and the dispersion aid is polyvinylpyrrolidone (brand PVP-K30).

[0080] Negative sheet preparation:

[0081] The mixture of the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com