Titanium dioxide film electrode and preparation method thereof and application

A thin-film electrode, titanium dioxide technology, applied in chemical instruments and methods, electrodes, circuits, etc., can solve the problems of low photon efficiency, increase energy consumption, etc., and achieve the effect of inhibiting recombination, realizing effective utilization, and promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] As a method for preparing a titanium dioxide thin film electrode according to an embodiment of the present invention, the method comprises the following steps:

[0040] (1) 0.058g of antimony trichloride, 0.72mL of tetrabutyl titanate, 30mL of deionized water and 30mL of hydrochloric acid solution with a mass fraction of 37% were mixed and dissolved to obtain a mixed solution A;

[0041](2) Clean the FTO conductive glass with acetone, ethanol and deionized water respectively, place the mixed solution A obtained in step (1) in a high-pressure reactor with a polytetrafluoroethylene liner, and conduct the FTO after cleaning The glass is immersed in the mixed solution A, with the FTO conductive glass facing down, and then reacted at 170°C for 6h;

[0042] (3) Rinse the FTO conductive glass treated in step (2) with deionized water after cooling, dry at 80° C. for 5 hours, and then heat-treat at 500° C. for 4 hours in a muffle furnace to obtain the titanium dioxide film elect...

Embodiment 2

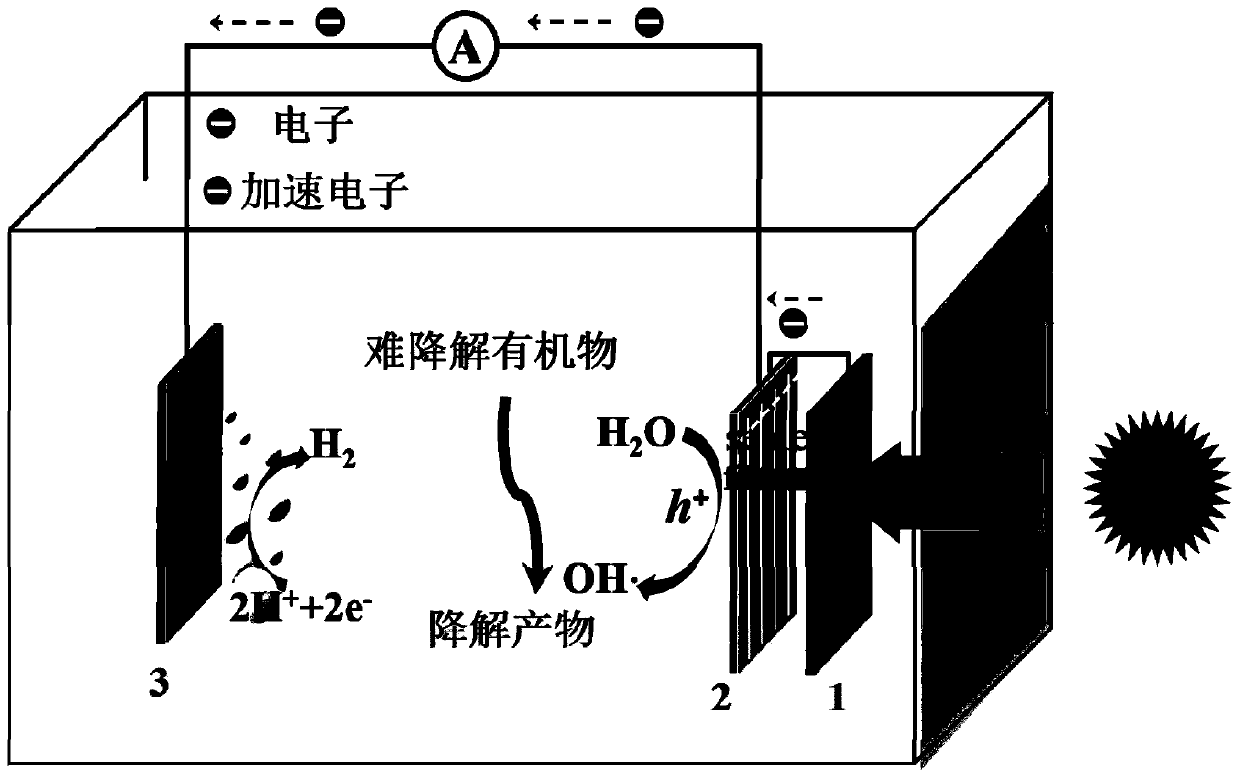

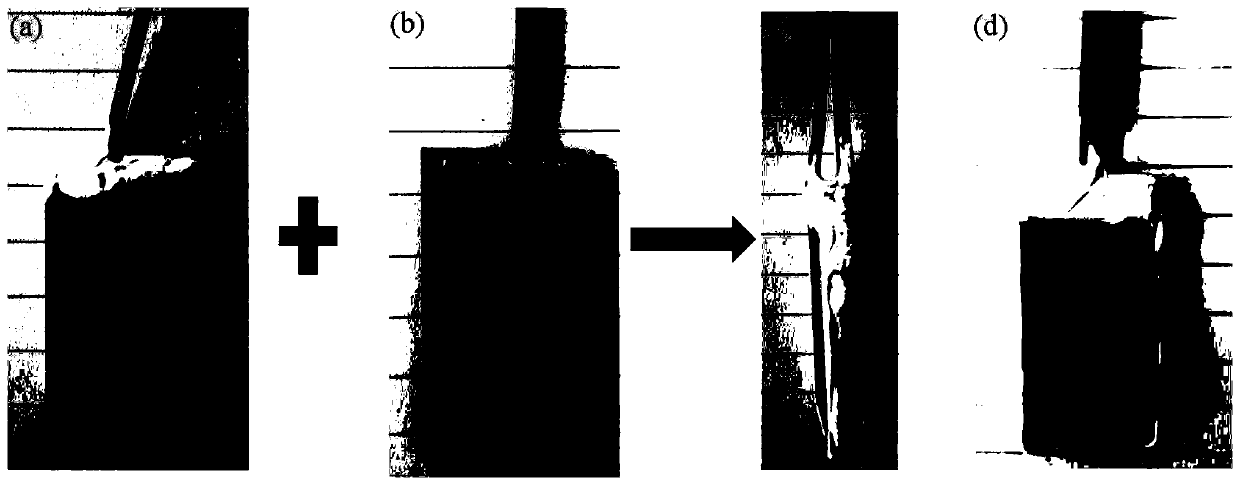

[0045] As a kind of photoanode of the embodiment of the present invention, such as figure 2 As shown, the photoanode includes a monocrystalline silicon cell and a titanium dioxide thin film electrode as described in Example 1. The monocrystalline silicon cell has a front side and a reverse side, and the front side of the monocrystalline silicon cell is relatively smooth. The opposite side of battery sheet has positive pole and negative pole, and the positive pole on the backside of described monocrystalline silicon battery sheet is connected with the front side of titanium dioxide thin film electrode as described in embodiment 1 by wire A, and the front side of titanium dioxide thin film electrode is the front side of FTO conductive glass On the corresponding surface, one end of the wire A is bonded to the front top of the titanium dioxide thin film electrode through conductive silver glue and the other end of the wire is welded to the positive electrode on the reverse side of...

Embodiment 3

[0048] As a kind of photovoltaic cell of the embodiment of the present invention, the anode of the photovoltaic cell is the photoanode as described in embodiment 2, the cathode of the photovoltaic cell is a platinum electrode, and the electrolyte of the photovoltaic cell is an aqueous sodium sulfate solution of 0.1-0.5M, The platinum electrode and the photoanode described in Example 2 were immersed in a 0.1-0.5 M sodium sulfate aqueous solution in parallel while maintaining a certain distance.

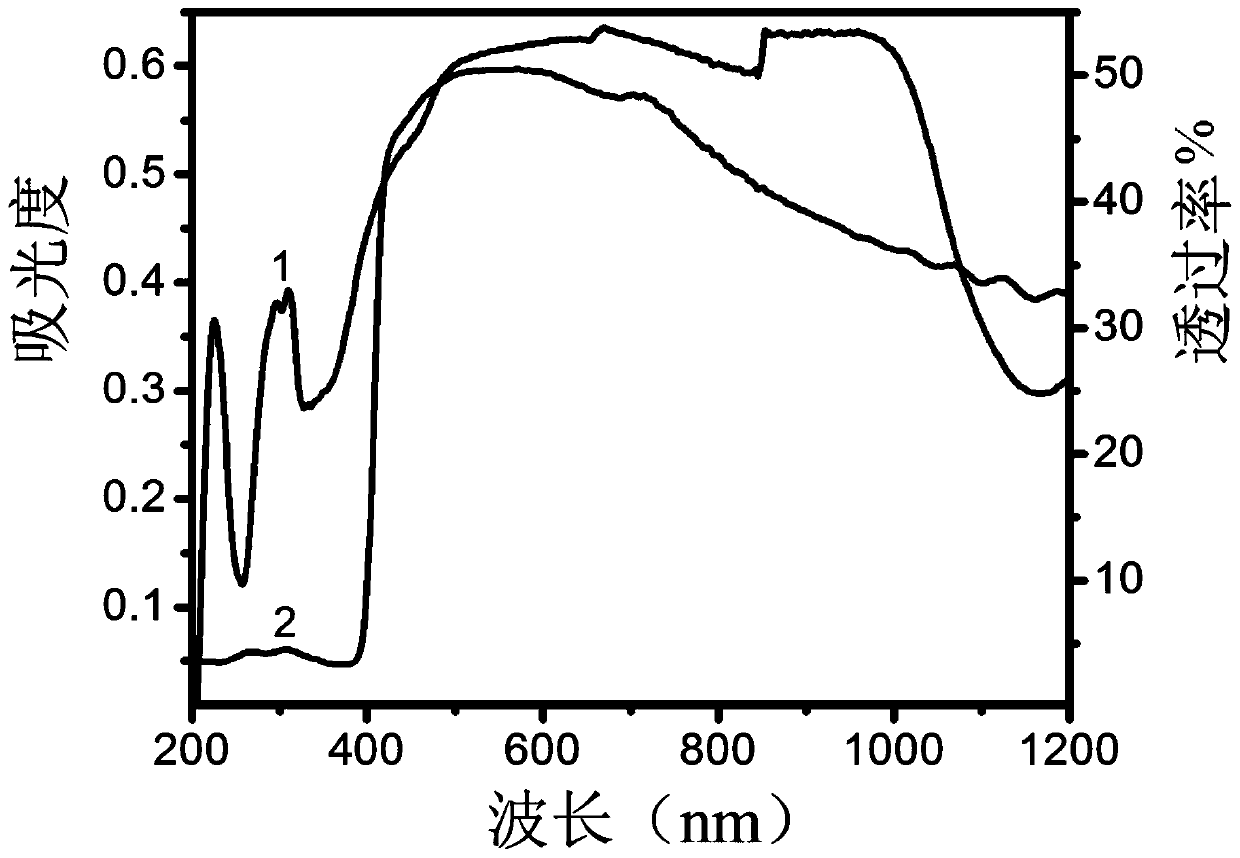

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com