Barrier degradable antibacterial food fresh-keeping film, and preparation method and application thereof

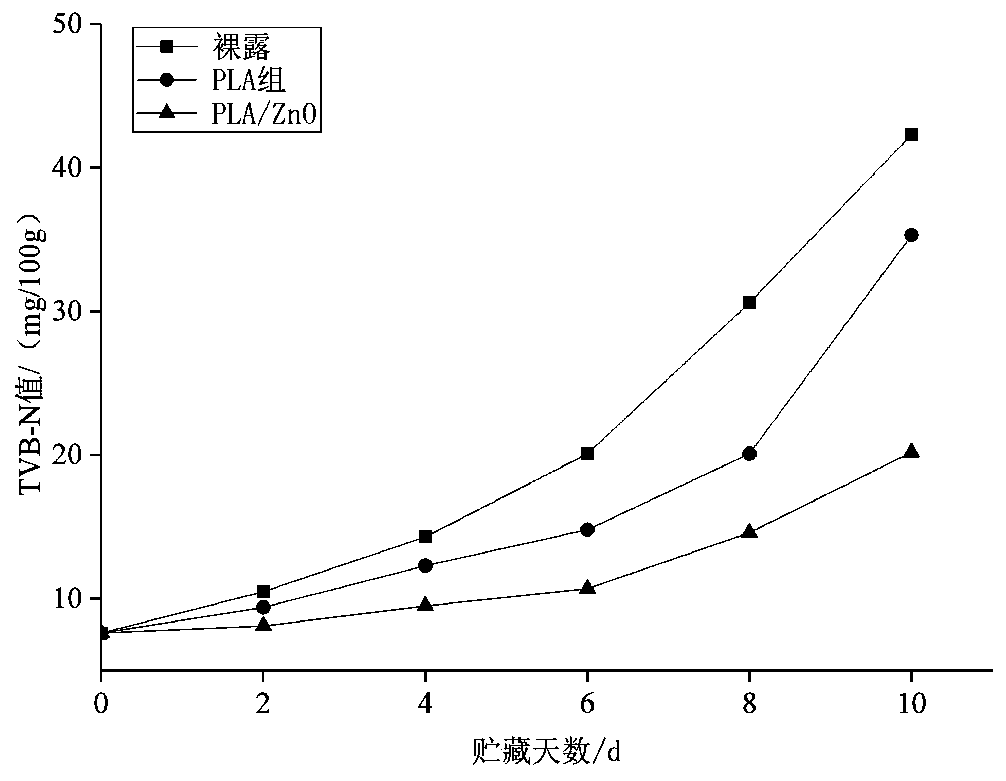

A food preservation and barrier technology, which is applied in the field of preparation of barrier degradable antibacterial food preservation film, can solve the problems of high requirements for processing equipment, non-degradation, and unfriendly environmental protection, and achieve strong environmental protection performance, good barrier performance, good The effect of competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

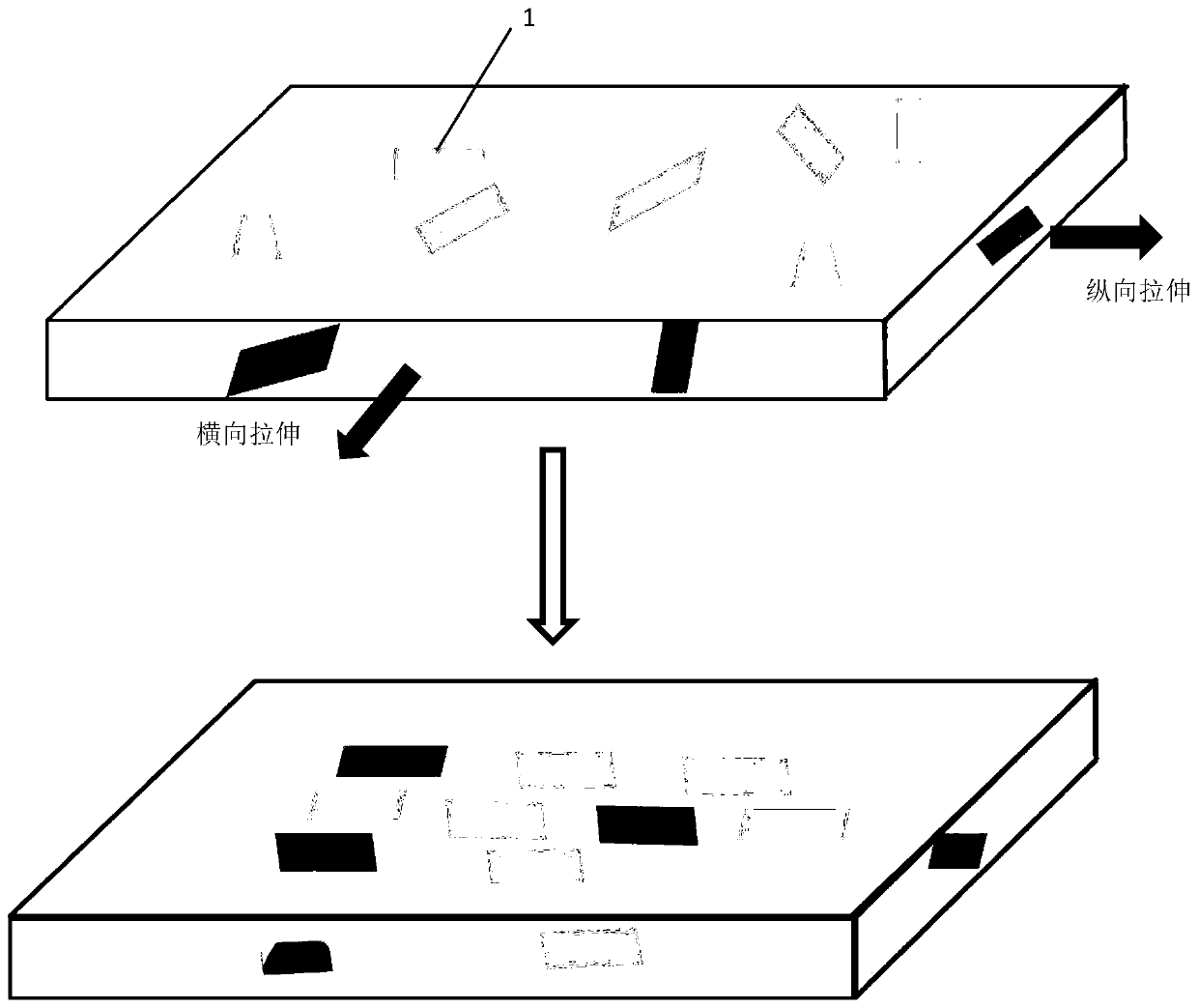

Method used

Image

Examples

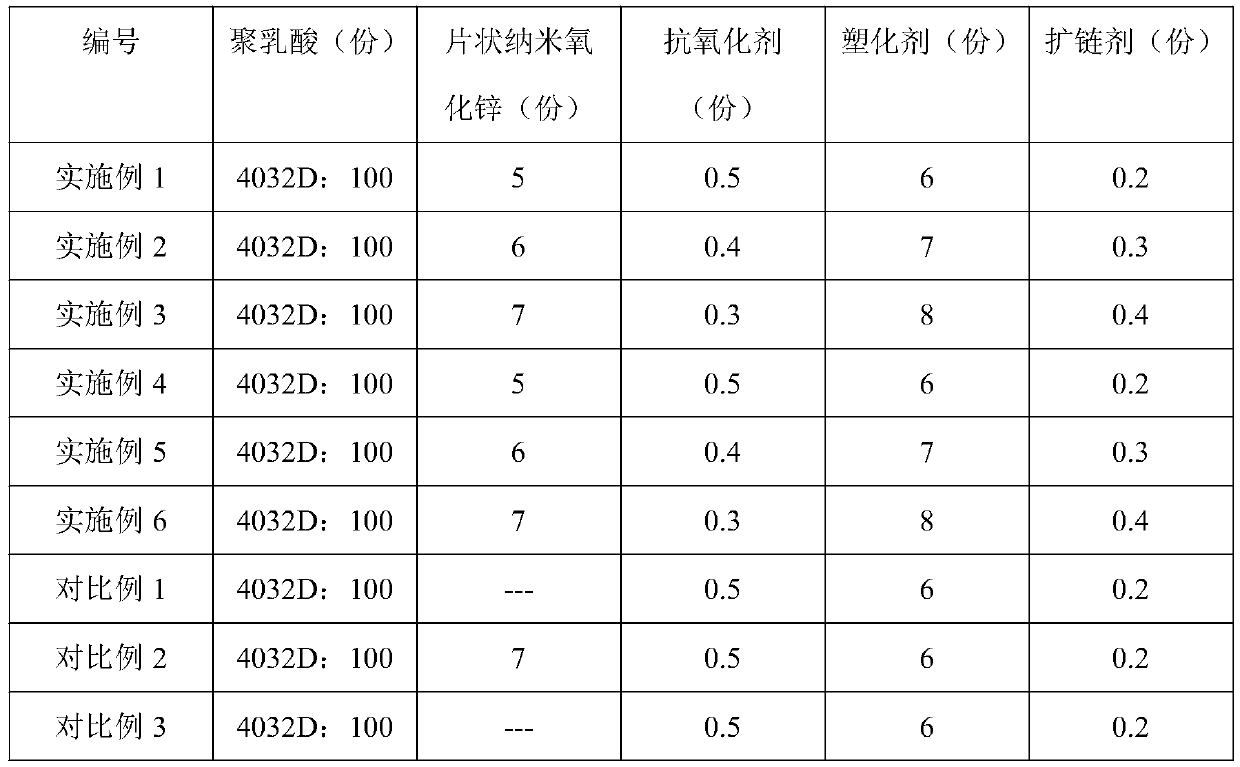

Embodiment 1

[0034] A preparation method of a degradable barrier film for antibacterial food, comprising the steps of:

[0035] (1) Preparation of plasticizer:

[0036] Glycerol 9%, monoacetin 50%, diacetin 20%, triacetin 20%, 1,4-butanediol 0.5%, adipic acid 0.3%, TNP After mixing at a ratio of 0.2%, the mixture was obtained, and an addition reaction was carried out, the reaction temperature was controlled at 70°C, and the reaction time was 4 hours to obtain a plasticizer;

[0037] (2) Melt blending:

[0038] Then 100 parts by weight of polylactic acid resin PLA (purchased from U.S. Natureworks to produce, trade mark 4032D) and vacuum-dried flaky nano-zinc oxide of 5 parts by weight, 0.5 part by weight of antioxidant 245, weight part Mix 6 parts of plasticizer and 0.2 parts by weight of chain extender ADR4300 in a high-speed mixer; put the mixed material into the feeder of LSSHJ-20 twin-screw extruder, and the material enters through the feeder In the twin-screw, the screw is melted an...

Embodiment 2

[0043] A preparation method of a degradable barrier film for antibacterial food, comprising the steps of:

[0044] (1) Preparation of plasticizer:

[0045] Glycerol 9%, monoacetin 50%, diacetin 20%, triacetin 20%, 1,4-butanediol 0.5%, adipic acid 0.3%, TNP After mixing at a ratio of 0.2%, an addition reaction is carried out, the reaction temperature is controlled at 70°C, and the reaction time is 4 hours to obtain a plasticizer;

[0046] (2) Melt blending:

[0047] 100 parts by weight of polylactic acid resin PLA (purchased from U.S. Natureworks to produce, trade mark 4032D) and vacuum-dried 6 parts by weight of flaky nano-zinc oxide, 0.4 parts by weight of antioxidant 245, parts by weight of air-dried 7 parts of plasticizer and 0.3 parts by weight of chain extender are mixed evenly in a high-speed mixer; the mixed material is added to the feeder of the LSSHJ-20 twin-screw extruder, and the material enters the twin-screw through the feeder In the process, the screw is melte...

Embodiment 3

[0053] A preparation method of a degradable barrier film for antibacterial food, comprising the steps of:

[0054] (1) Preparation of plasticizer

[0055] Glycerol 9%, monoacetin 50%, diacetin 20%, triacetin 20%, 1,4-butanediol 0.5%, adipic acid 0.3%, TNP0 in parts by mass .2% ratio mixed for addition reaction, the reaction temperature was controlled at 70°C, and the reaction time was 4 hours to prepare the plasticizer;

[0056] (2) Melt blending

[0057] 100 parts by weight of polylactic acid resin PLA (purchased from U.S. Natureworks production, trade mark 4032D) after blast drying and 7 parts by weight of vacuum-dried flaky nano-zinc oxide, 0.3 parts by weight of antioxidant 245, parts by weight 8 parts of plasticizer and 0.4 parts by weight of chain extender are mixed evenly in a high-speed mixer; the mixed material is added to the feeder of the LSSHJ-20 twin-screw extruder, and the material enters the twin-screw extruder through the feeder In the process, the screw is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com