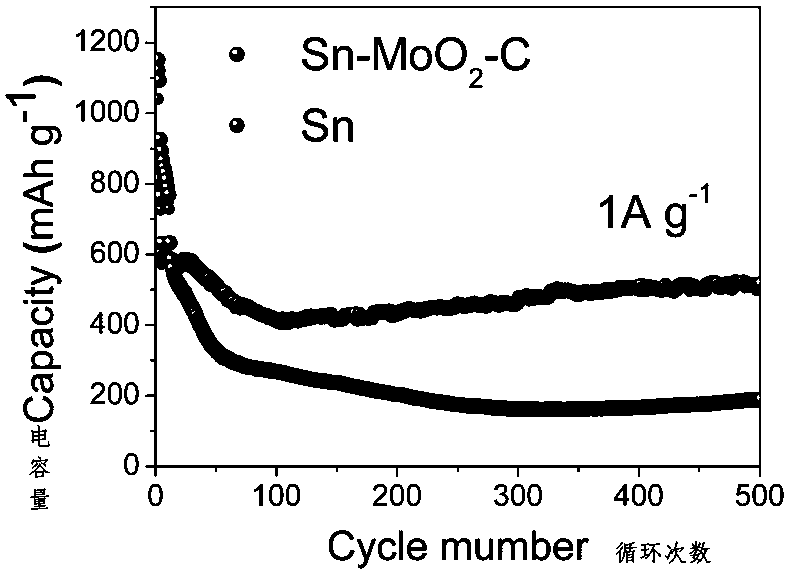

Preparation method of superstructure tin carbon-molybdenum oxide composite material and application of superstructure tin carbon-molybdenum oxide composite material to electrode

A composite material and superstructure technology, applied in the field of electrodes, can solve the problems of reducing the cycle performance of electrode materials, short cycle life of tin-based materials, unstable SEI films, etc., to improve chemical activity and utilization, inhibit volume expansion, and improve The effect of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a superstructure tin-carbon-molybdenum oxide composite material, comprising the following steps:

[0028] (1) Prepare a tris aqueous solution so that the pH of the solution is 10;

[0029] (2) Weigh an appropriate amount of phosphomolybdic acid hydrate and dissolve it in trimethylaminomethane aqueous solution, the content of phosphomolybdic acid hydrate is 0.02 mol / L; The concentration of nanometer tin dioxide is 0.01 mol / L;

[0030] (3) preparing the same volume of dopamine hydrochloride in tris aqueous solution as in step (2), the concentration of said dopamine hydrochloride being 0.02 mol / L;

[0031] (4) Pour the dopamine hydrochloride solution obtained in step (3) into the mixed solution in step (2), stir for 5 minutes, and let stand for 2 hours;

[0032] (5) Pour off the supernatant of the product solution in step (4), centrifuge the lower precipitate, wash with deionized water and absolute ethanol for 2 to 3 times, and dry at 70°C in a bl...

Embodiment 2

[0036] A preparation method of a superstructure tin-carbon-molybdenum oxide composite material, comprising the following steps:

[0037] (1) Prepare aqueous sodium hydroxide solution so that the pH of the solution is 9.5;

[0038] (2) Weigh an appropriate amount of sodium phosphomolybdate hydrate and dissolve it in aqueous sodium hydroxide solution, wherein the content of sodium phosphomolybdate hydrate is 0.02 mol / L; weigh an appropriate amount of nano-tin powder and disperse it ultrasonically, and nano-tin The concentration of powder is 0.01 mol / L;

[0039](3) Weigh an appropriate amount of dopamine hydrochloride and dissolve it in the same volume of sodium hydroxide solution as in step (2), and stir to fully dissolve dopamine hydrochloride, wherein the concentration of dopamine hydrochloride is 0.02 mol / L;

[0040] (4) Pour the dopamine hydrochloride solution obtained in step (3) into the mixed solution in step (2), stir for 5 minutes, and let stand for 2 hours;

[0041] ...

Embodiment 3

[0045] A preparation method of a superstructure tin-carbon-molybdenum oxide composite material, comprising the following steps:

[0046] (1) Prepare a mixed solution of ammonia water and ethanol, in which the volume ratio of water and ethanol is 1:1, and the pH value of the solution is 10;

[0047] (2) Weigh an appropriate amount of phosphomolybdic acid hydrate and dissolve it in the mixed solution of ammonia water and ethanol, wherein the content of phosphomolybdic acid hydrate is 0.2 mol / L; The concentration of tin oxide is 0.1mol / L;

[0048] (3) Weigh an appropriate amount of dopamine hydrochloride and dissolve it in the same volume of ammonia water and ethanol mixed solution as in step (2), and stir to fully dissolve dopamine hydrochloride, wherein the concentration of dopamine hydrochloride is 0.2mol / L;

[0049] (4) Pour an equal volume of the dopamine hydrochloride solution obtained in step (3) into the mixed solution in step (2), stir for 5 minutes, and let stand for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com