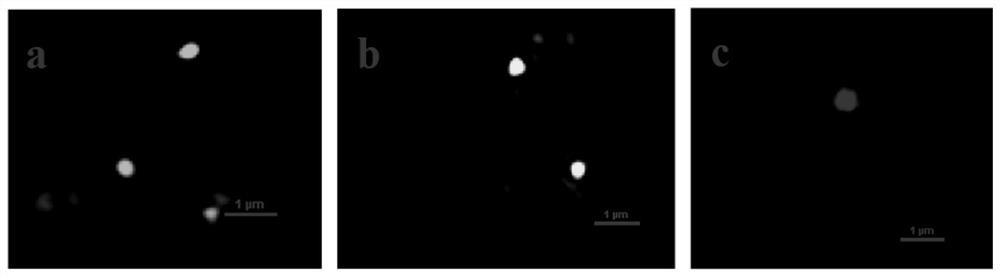

A fluorescent polymer microsphere loaded with quantum dots and its preparation method

A technology of fluorescent polymers and quantum dots, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of difference in fluorescence brightness, decline in fluorescence performance, poor stability, etc., and achieve stable and durable fluorescence performance. Change the fluorescence intensity, good effect of monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The synthesis of embodiment 1 macromolecule RAFT reagent PAA-TTC

[0033]Acrylic acid (AA) (14.41g, 200mmol), S-1-dodecyl-S'-(α,α'-dimethyl-α"-acetic acid) trithiocarbonate (DDMAT) (0.1826g , 0.5mmol) and azobisisobutyronitrile (AIBN) (8.23mg, 0.05mmol) were added in a 150mL flask, dissolved with 1,4-dioxane (48.6g), and the solution was ventilated with nitrogen for 30 minutes Degassed, then immersed in a preheated oil bath at 70 °C for 2 hours, after cooling, the product was precipitated into diethyl ether and purified by a precipitation / filtration cycle. After drying at room temperature under vacuum, a yellow large Molecular RAFT agent PAA-TTC polymer powder, molecular weight about 20000.

[0034]

Embodiment 2

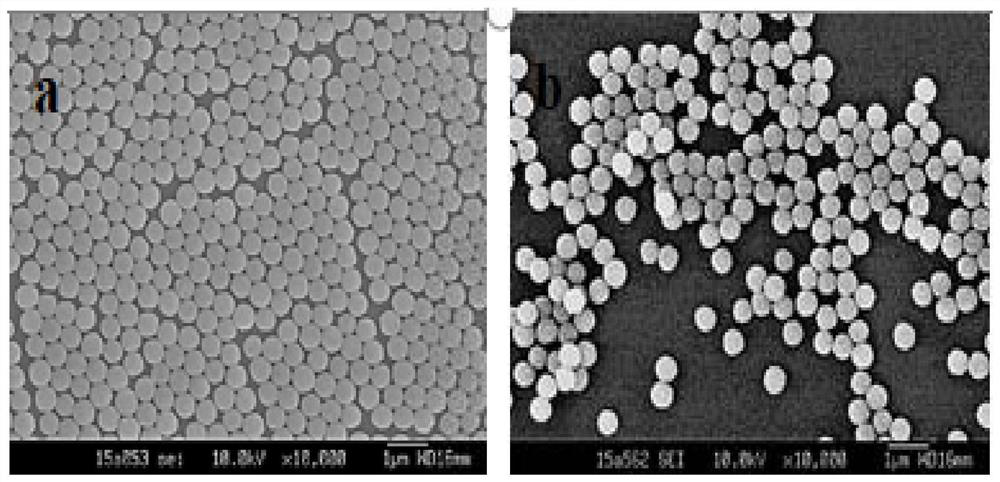

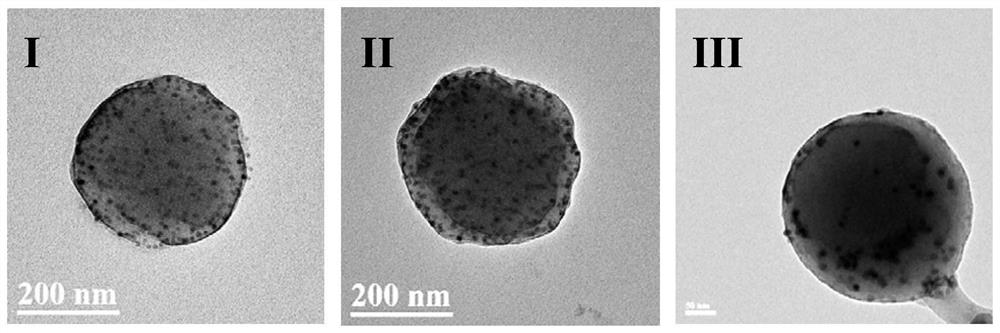

[0035] Example 2 Synthesis of cross-linked PMGA microspheres based on PAA-TTC

[0036] The weight ratio of ethanol / water mixture 40 / 60 (7.2g+10.8g) was introduced in a 25mL round bottom flask as a solvent, and then 2.0g of glycidyl methacrylate GMA monomer (10wt% relative to the system) was added, The stabilizing dispersant PAA-TTC of 0.30g (15wt% with respect to monomer), the DDMAT of 0.005g (0.25wt% with respect to monomer), the Darocur1173 of 0.06g (3wt% with respect to monomer) and 0.06g dipropylene glycol diol Acrylic acid (3 wt% relative to monomer), dissolved with magnetic stirring. The reaction mixture was deoxygenated with nitrogen for 30 minutes, sealed with a glass stopper with a quartz glass sheet, and then illuminated with a 365nm wavelength LED lamp (light intensity 2.5mW / cm2) under constant stirring. 2 ) was irradiated from the top of the round bottom flask for 3 hours. The product is separated by centrifugation, washed with ethanol / water (40 / 60, w / w), and cen...

Embodiment 3

[0038] The weight ratio of ethanol / water mixture 40 / 60 (7.6g+11.4g) was introduced in a 25mL round bottom flask as a solvent, and then 1.0g of glycidyl methacrylate GMA monomer (5wt% relative to the system) was added, The stabilizing dispersant PAA-TTC of 0.10g (10wt% with respect to monomer), the DDMAT of 0.005g (0.25% with respect to monomer), the Darocur 1173 of 0.01g (1wt% with respect to monomer) and 0.03g dipropylene glycol diol Acrylic acid (3 wt% relative to monomer), dissolved with magnetic stirring. The reaction mixture was deoxygenated with nitrogen for 30 minutes, sealed with a glass stopper with a quartz glass sheet, and then illuminated with a 365nm wavelength LED lamp (light intensity 2.5mW / cm2) under constant stirring. 2 ) was irradiated from the top of the round bottom flask for 3 hours. The product was separated by centrifugation, washed with ethanol / water (40 / 60, w / w), and repeatedly centrifuged and washed 2 to 3 times to obtain cross-linked PGMA polymer mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com