Preparation method of flame-retardant electrolyte by using 2,4,6-trioxo-1,3,5-triazine-triphosphate lithium salt and compound thereof

A lithium triphosphate and electrolyte technology, which is applied in the field of preparation of flame-retardant electrolytes for lithium-ion batteries, can solve the problems of difficulty in meeting the needs of high-performance lithium-ion batteries, few reports of flame-retardant electrolytes, low lithium ion concentration, etc., and achieve high yield , mild conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

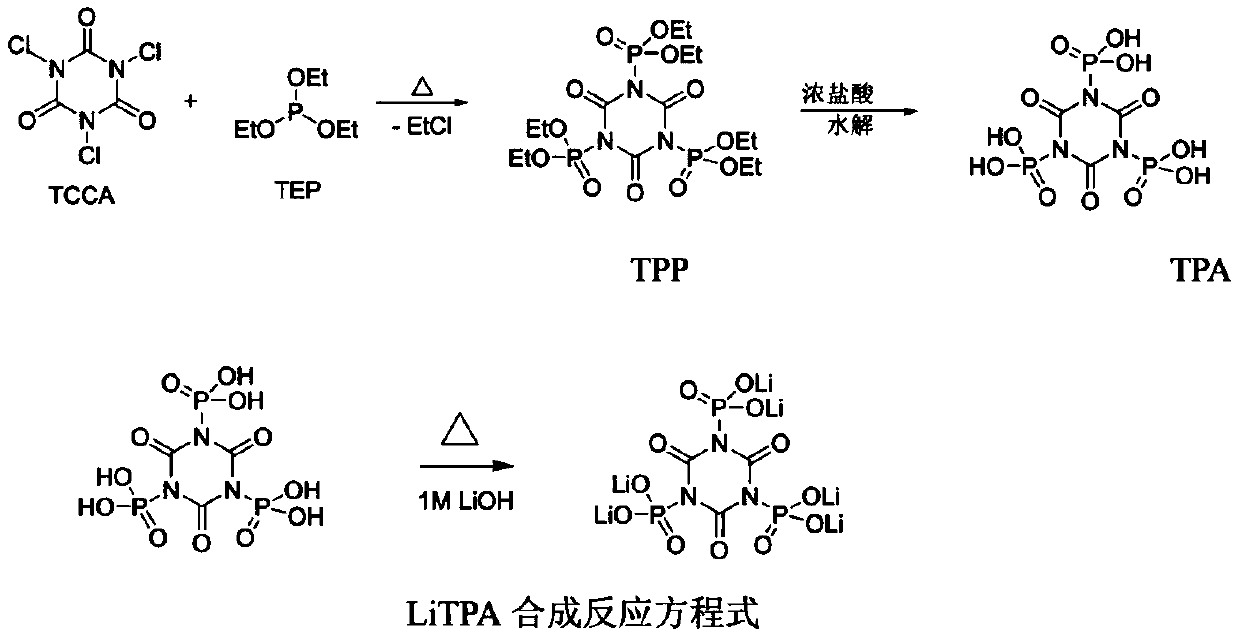

[0021] [Example 1]: the preparation of TTP:

[0022] Take 60mL of triethyl phosphite (TEP, 0.34mol) into a 200mL three-neck round bottom flask. Under magnetic stirring, divide 14g of trichloroisocyanuric acid (TCCA, 0.06mol) into four batches, slowly add it into triethyl phosphite within 2 hours at room temperature, TCCA dissolves rapidly, and the reaction releases a lot of heat, and releases ethyl chloride alkane gas to obtain a yellow transparent solution. After adding TCCA, raise the temperature to 80-120°C for 8-12 hours, cool to 50°C, evaporate unreacted triethyl phosphite under reduced pressure to obtain 22.9 g of colorless oily liquid, namely 1,3,5-tris Ethylazine-2,4,6-triphosphate (TTP, yield: 78%).

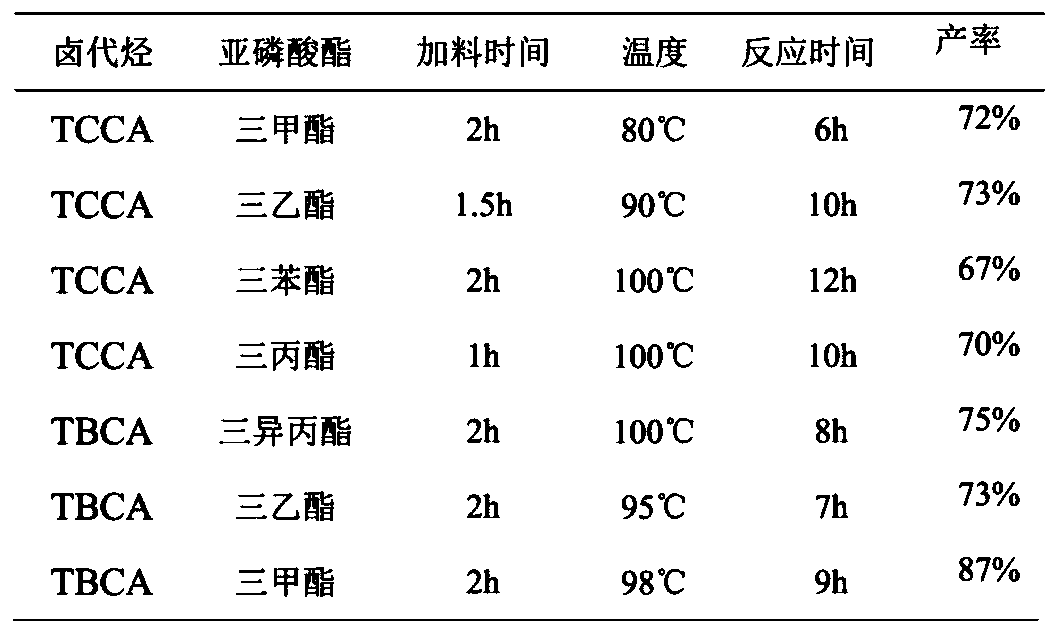

[0023] Adopt same reaction step, the productive rate that carries out reaction with different reactants or under different conditions is as shown in table 1:

[0024] Table 1 The reaction conditions for the preparation of TTP by the reaction of trihaloisocyanuric acid...

Embodiment 2

[0026] [Example 2]: the preparation of TPA:

[0027] Add 23.5g TTP (0.043mol) into 100mL concentrated hydrochloric acid, reflux for 72h under magnetic stirring, cool to 50°C, distill off HCl, ethanol and part of water under reduced pressure, concentrate to 40mL, extract three times with 90mL ethyl acetate, remove untreated Hydrolyzed TTP. The aqueous phase was concentrated to nearly dryness, and dried to constant weight in a vacuum oven at 120°C to obtain 8.9 g of white solid, namely 2,4,6-triketone-1,3,5-triazine-2,4,6 - Triphosphoric acid (TPA, yield: 87%).

[0028] Using the same reaction steps, but extracting with dichloromethane, benzene, toluene or petroleum ether, the yields were 84%, 80%, 82% and 76%, respectively.

[0029] Using the same reaction steps, reflux in concentrated hydrochloric acid for 12h, distill under reduced pressure at 70°C, and extract with ethyl acetate, the yield is 64%.

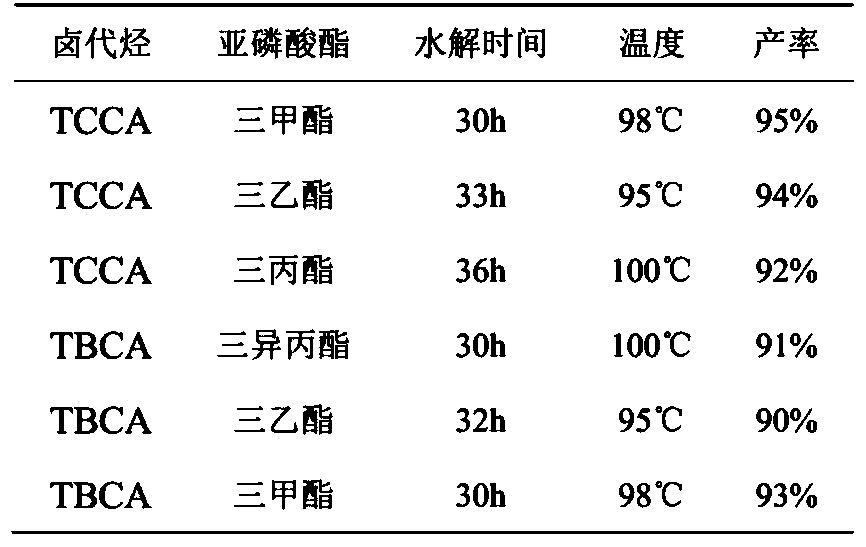

[0030] The hydrolysis of different ester groups of TTP prepares the produ...

Embodiment 3

[0033] [Example 3] The preparation of 2,4,6-trioxo-1,3,5-triazine-lithium triphosphate, the steps are as follows:

[0034]Take 7.3g of TPA powder (0.02mol) and place it in a beaker, add 20mL of deionized water, stir until completely dissolved, add 60mL of 1mol / L lithium hydroxide solution dropwise to obtain a colorless and clear solution; Reflux for 6 hours, add 20mL of ethanol after cooling, let it stand overnight, a white precipitate is formed, filter with suction, and recrystallize the obtained solid with a liquid of equal volume ratio between deionized water and ethanol, and the obtained pure product is vacuum After drying, 7.5 g of LiTPA white solid was obtained.

[0035] Solubility test: at room temperature, the solubility in an equal volume ratio of ethylene carbonate / dimethyl sulfoxide / N-methylpyrrolidone mixed solvent is 42-87g / L;

[0036] Conductivity test: at room temperature, the conductivity of ethylene carbonate / dimethyl sulfoxide / N-methylpyrrolidone mixed solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com