Recovery method of positive electrode material of waste ternary lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of recycling waste ternary lithium-ion battery positive electrode materials, can solve the problems of complex recycling process, long process flow, and low recovery rate, and achieve simplified process, cost reduction, and high-efficiency recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Discharge the waste ternary lithium-ion battery, disassemble to obtain the positive electrode, negative electrode and separator, put the positive electrode in 30v / v% ethanol for cleaning, dry it and place it in a muffle furnace to heat up to 400°C for calcination 2h, continue to heat up to 600°C and calcined for 2h to remove the binder on the pole piece;

[0032] 2) Mechanically pulverize the calcined positive electrode sheet and pass through a 150-mesh sieve to separate the powder from the current collector, and collect the powder to be the positive electrode powder;

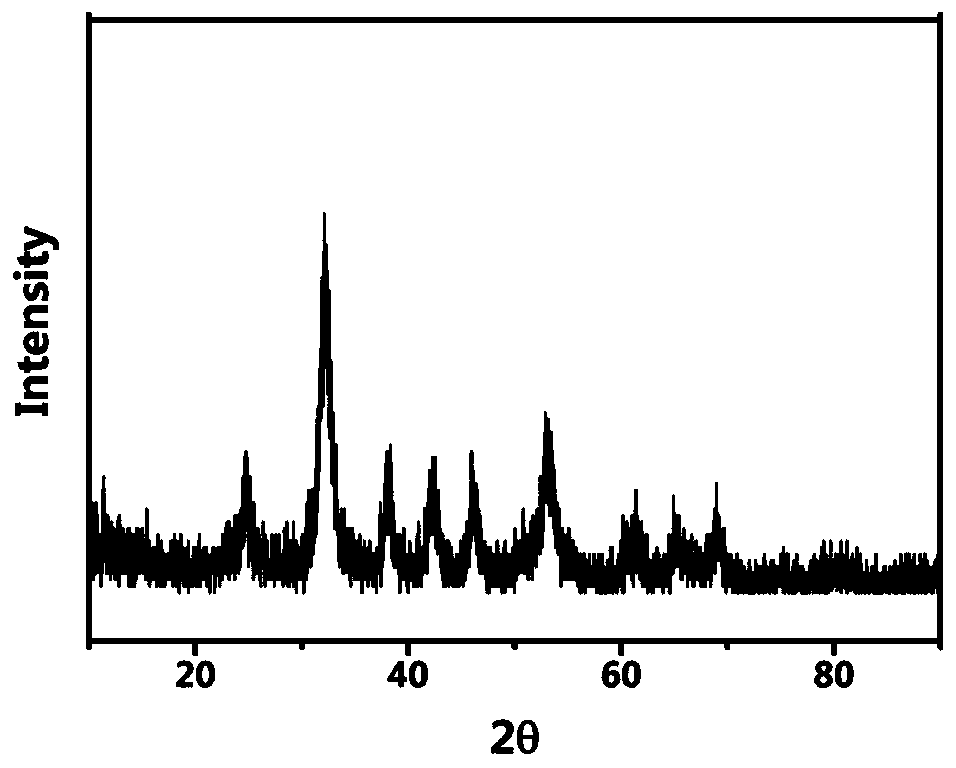

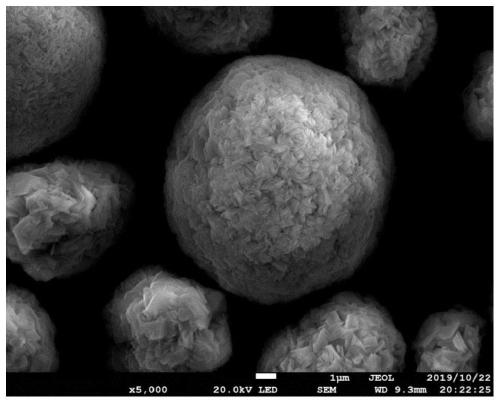

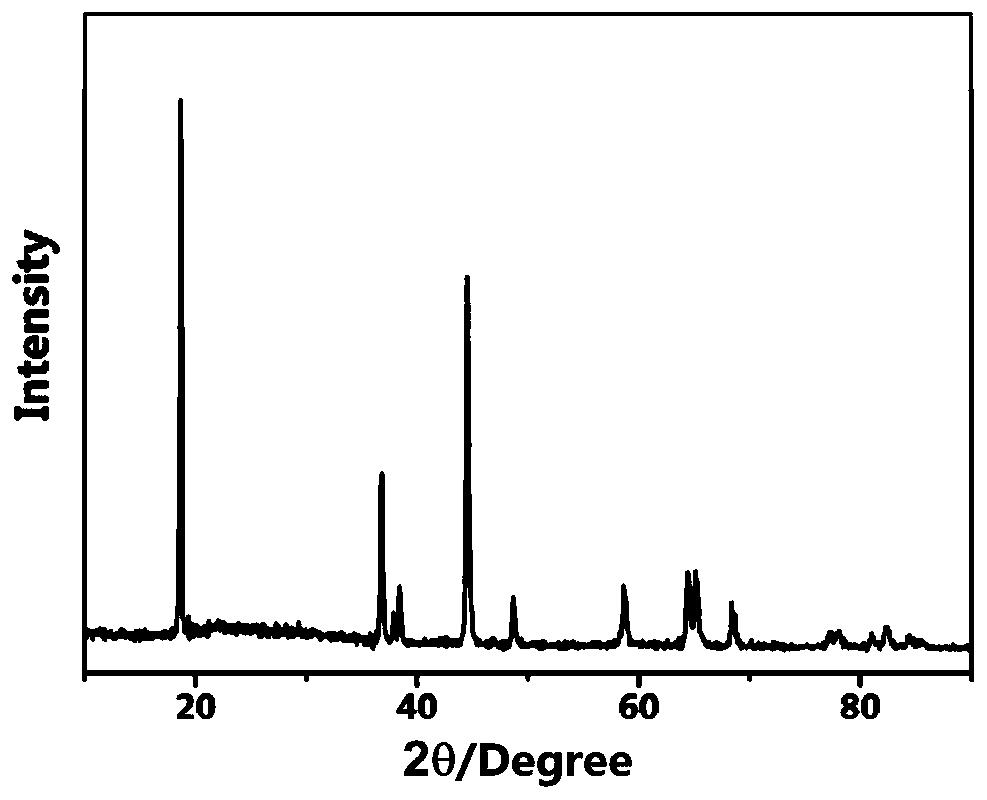

[0033] 3) The positive electrode powder is leached with 2mol / L sulfuric acid and 5vol% hydrogen peroxide, the solid-to-liquid ratio is 40g:1L, the leaching temperature is 85°C, and the leaching time is 80min, and the solid-liquid separation is carried out on the material to obtain Leaching solution and leaching slag; the content of nickel ion, cobalt ion, manganese ion and lithium ion in the leach sol...

Embodiment 2

[0040] 1) Discharge the waste ternary lithium-ion battery, disassemble to obtain the positive electrode, negative electrode and separator, put the positive electrode in 60v / v% ethanol for cleaning, dry it and place it in a muffle furnace to heat up to 550°C for calcination 6h, remove the adhesive on the pole piece;

[0041] 2) Mechanically pulverize the calcined positive electrode sheet and pass through a 150-mesh sieve to separate the powder from the current collector, and collect the powder to be the positive electrode powder;

[0042] 3) Leach the positive electrode powder with 1.5mol / L nitric acid and 4.5wt% citric acid, the solid-liquid ratio is 45g:1L, the leaching temperature is 85°C, and the leaching time is 45min. Obtain leaching solution and leaching slag; measure the content of nickel ion, cobalt ion, manganese ion and lithium ion in the leaching solution, they are 16%, 17.1%, 16.4%, 5.2% respectively;

[0043] 4) Add nickel nitrate, cobalt nitrate, manganese nitra...

Embodiment 3

[0049] 1) Discharge the waste ternary lithium-ion battery, disassemble to obtain the positive electrode, negative electrode and separator, put the positive electrode in 75v / v% ethanol to clean, dry and heat up to 370°C in a muffle furnace for calcination 2h, continue to heat up to 600°C and calcined for 2h to remove the binder on the pole piece;

[0050] 2) Mechanically pulverize the calcined positive electrode sheet and pass through a 150-mesh sieve to separate the powder from the current collector, and collect the powder to be the positive electrode powder;

[0051] 3) Leach the positive electrode powder with 4mol / L acetic acid and 5wt% ammonium sulfite solution, the solid-to-liquid ratio is 30g:1L, the leaching temperature is 80°C, and the leaching time is 60min, and the material is subjected to solid-liquid separation, respectively Obtain leaching solution and leaching slag; measure the content of nickel ion, cobalt ion, manganese ion and lithium ion in the leaching soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com