Method for preparing olefin by catalyzing dehydration and deoxidation of polyhydroxy compound with organic molybdenum

A polyhydroxy compound, catalyzing polyhydroxyl technology, applied in the preparation of organic compounds, elimination of hydroxyl groups, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of limited polyols, easy sublimation, and high price , to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0103] According to one embodiment of the present application, the method for preparing olefins by using organic molybdenum to catalyze the deoxygenation and dehydration of vicinal diols is characterized in that: the use of cheap non-noble metal molybdenum as a catalyst.

[0104] Optionally, the organic ligands of the organomolybdenum catalyst include one or more of monodentate and multidentate ligands containing nitrogen, sulfur, oxygen, and phosphorus, and the molybdenum source includes: MoO 2 (acac) 2 ,MoO 2 Cl 2 , Ammonium heptamolybdate, molybdenum trioxide, sodium molybdate, etc. The molybdenum source and the organic ligand of the molybdenum-based catalyst come from a wide range of sources and are easy to obtain. The molybdenum-based catalyst is used in an amount of 1-20 mol%, preferably 0.5-15 mol%, and most preferably 3-10 mol%, of the raw material polyol.

[0105] Alternatively, compounds containing vicinal diol structures are substrates.

[0106] Optionally, use...

Embodiment 1

[0110] Embodiment 1 Preparation of nitrogen-containing organic ligand molybdenum-based catalyst

[0111] use, MoO 2 (acac) 2 It is the precursor of molybdenum (0.2mmol), dissolved in 20mL of methanol. At the same time, phenanthroline (0.25 mol) was dissolved in 20 mL of methanol. After completely dissolving, the methanol solution of the molybdenum precursor was added dropwise to the methanol solution of the nitrogen-containing ligand, and aged at room temperature for 24 hours. Suction filtration, washing with methanol, vacuum drying at room temperature, grinding, the code is Mo-phen.

[0112] Put 0.25mmol substrate tartaric acid, 10mol% Mo-phen (relative to the substrate), and 5mL n-butanol in a 38mL pressure-resistant tube, in a 160°C oil bath, and react for 20h. After the reaction, put it in ice Cool down to room temperature in a water bath. Get reaction solution 1.15mL, add internal standard durene 1mL (the acetonitrile solution of 0.005g / mL durene, quantitative analysi...

Embodiment 2

[0114] Embodiment 2 nitrogen-containing, the preparation of oxygen organic ligand molybdenum-based catalyst

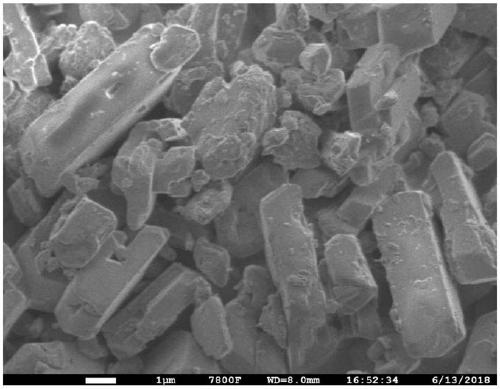

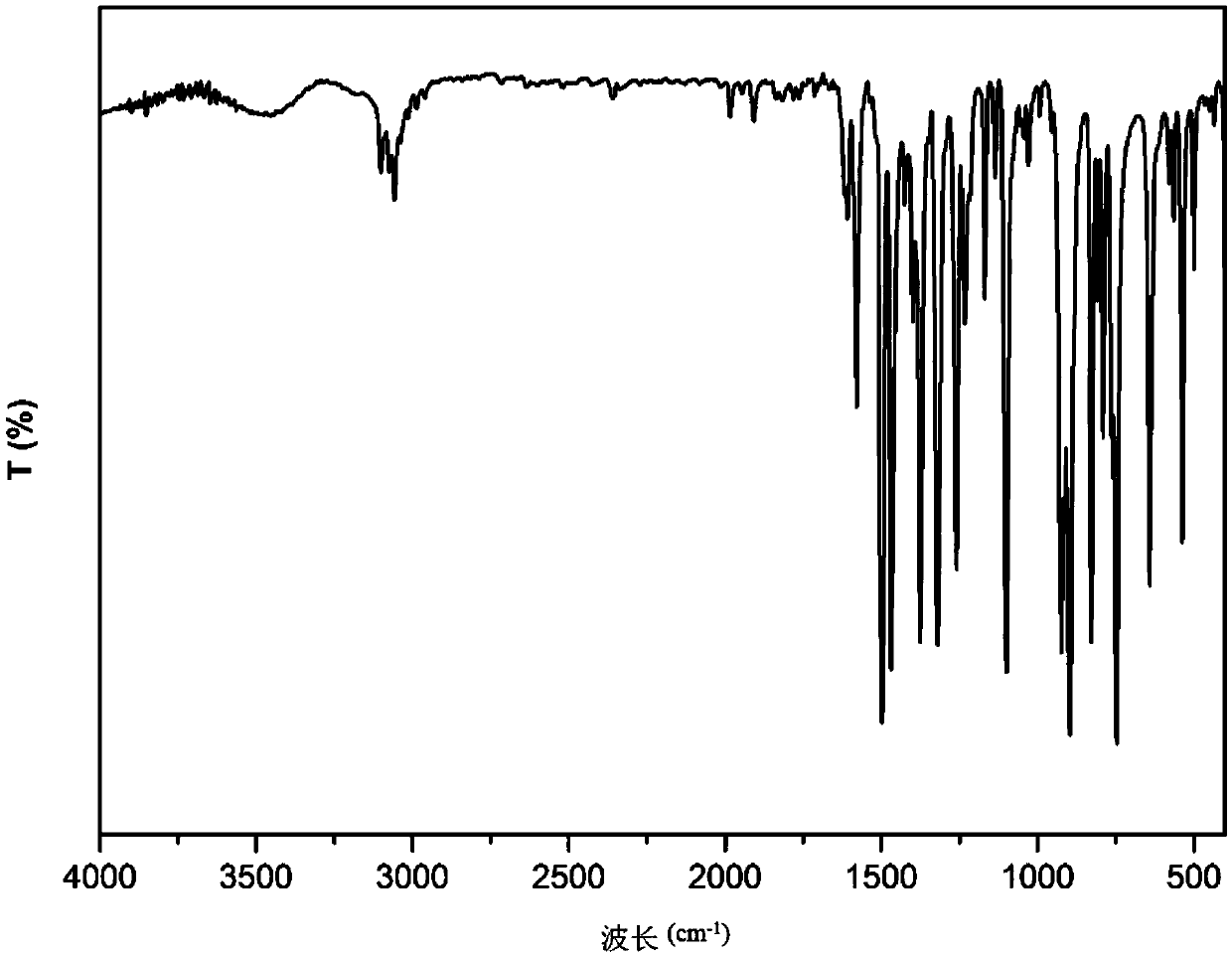

[0115] Use MoO 2 (acac) 2 It is the precursor of molybdenum (0.2mmol), dissolved in 20mL of methanol. At the same time, 8-hydroxyquinoline (0.25mmol) was dissolved in 20mL of methanol, and after being completely dissolved, the MoO 2 (acac) 2The methanol solution was poured into the methanol solution of 8-hydroxyquinoline, aged at room temperature for 24h. Suction filtration, washing with methanol, vacuum drying at room temperature, grinding, the code is MoO 2 (oxine) 2 . Use FITR, UV-Vis, NMR, XRD, SEM, TEM, X-ray single crystal diffraction to analyze its composition, structure and morphology. The results show that the catalyst is a single crystal with a prism-like structure stacked in layers.

[0116] typical, figure 1 for MoO 2 (oxine) 2 The scanning electron microscope photo, from the figure can be seen layer upon layer of prism-like.

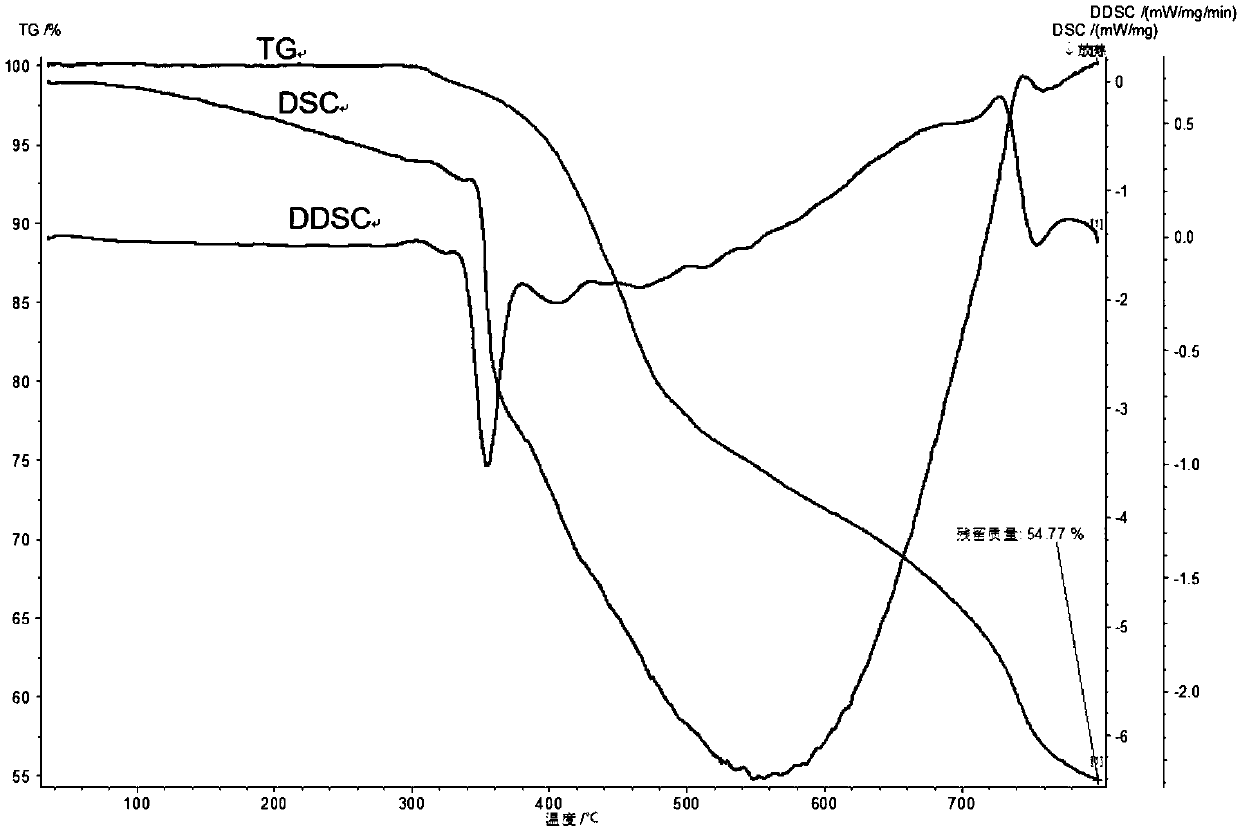

[0117] figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com