Resource treatment method for smelting flue gas washing wastewater

A technology of smelting flue gas and recycling, which is applied in the direction of gaseous effluent wastewater treatment, chemical instruments and methods, and multi-stage water treatment. It can solve the problems of inconvenient separation and recovery of arsenic, avoid secondary pollution, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

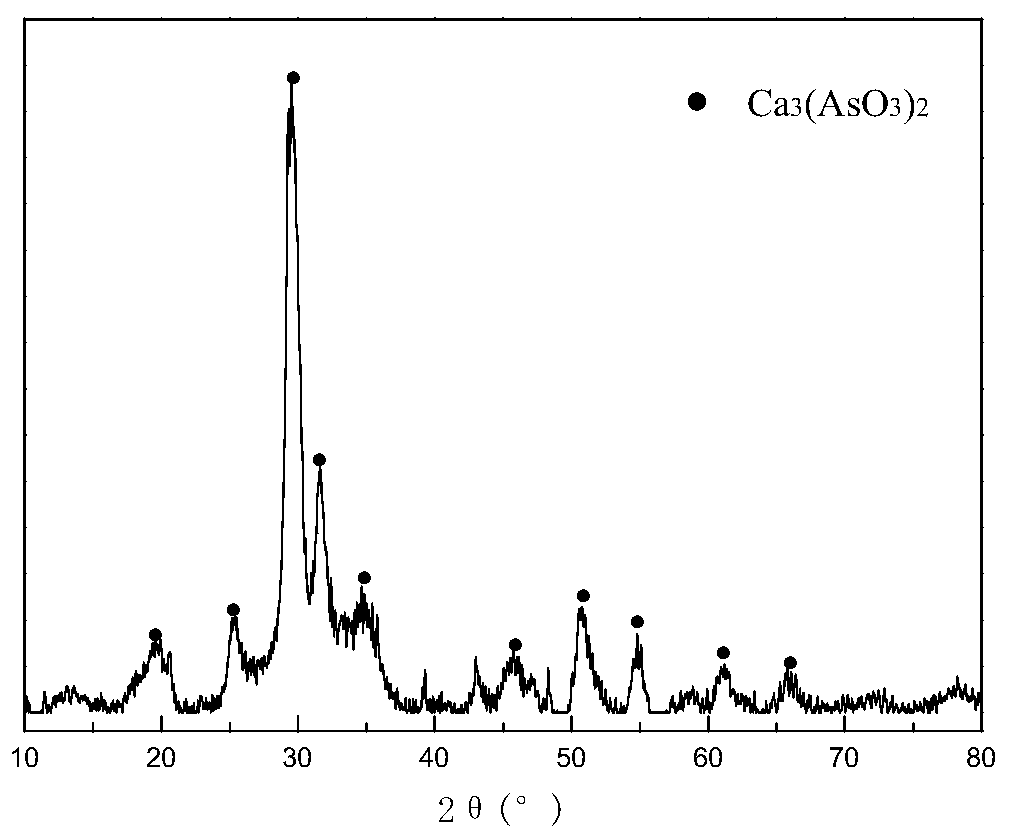

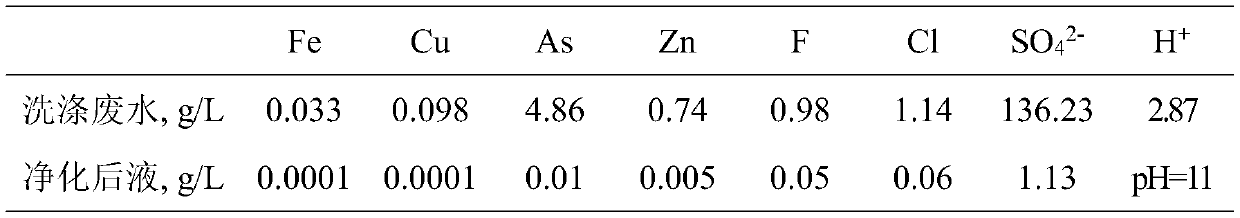

[0039] Take 2.5m of smelting flue gas washing wastewater 3 , stirring to add calcium iodide, the I - The ion concentration is increased to 0.006mg / L, and the residual H in the wastewater is used 2 SO 3 As reducing agent, in I - Under the catalysis of ions, reduce As(V) to As(III), react at room temperature for 15 minutes, then add negative 150 mesh limestone powder, adjust the pH of the solution to 2.3, and filter to obtain calcium sulfate filter cake containing 0.02% As and Reduction and neutralization liquid; the obtained reduction and neutralization liquid is added with titanium, zirconium and silicon containing 2.3% of Ti, 5.6% of Zr, 21.8% of Si and 13.6% of Al according to the mass ratio of the fluorine contained in it to the defluorinating agent of 1:50. , aluminum oxide and its hydrate, adjust the pH of the solution to 3.5, stir at 20°C for 0.5h, filter the defluorinated liquid and the loaded defluorinated agent, and regenerate the loaded defluorinated agent with so...

Embodiment 2

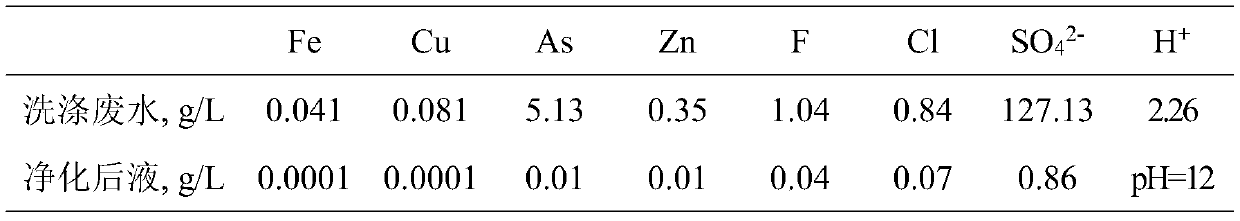

[0043] Take 5m of smelting flue gas washing wastewater 3 , into SO 2 To saturation, stir at room temperature for 24 hours to reduce As(V) to As(III), then add negative 180-mesh limestone powder to adjust the pH of the solution to 2.7, filter to obtain a calcium sulfate filter cake containing 0.03% As and reducing medium And after the liquid; the obtained reduction and neutralization liquid is added with Ti 6.8%, Zr1.3%, Ca 0.8%, Si 19.6%, Al 12.8% titanium, A defluorinating agent composed of oxides of zirconium, calcium, silicon, aluminum and their hydrates, adjust the pH of the solution to 3.9, stir at 25°C for 1 hour, filter to obtain the defluorinated liquid and the loaded defluorinating agent, and use sodium carbonate for the loaded defluorinating agent After the solution is regenerated, it is returned to recycling, and sodium carbonate is added to the desorbed solution, and NaF is crystallized by the same ion effect; the defluorinated solution is adsorbed by D231 strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com