Synthesis method of metoprolol succinate isomer impurities

A technology for the synthesis of metoprolol succinate and a synthetic method, which is applied in the field of synthesis of metoprolol succinate isomer impurities, can solve problems such as difficult separation and purification, and achieve simple operation, mild reaction conditions, and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

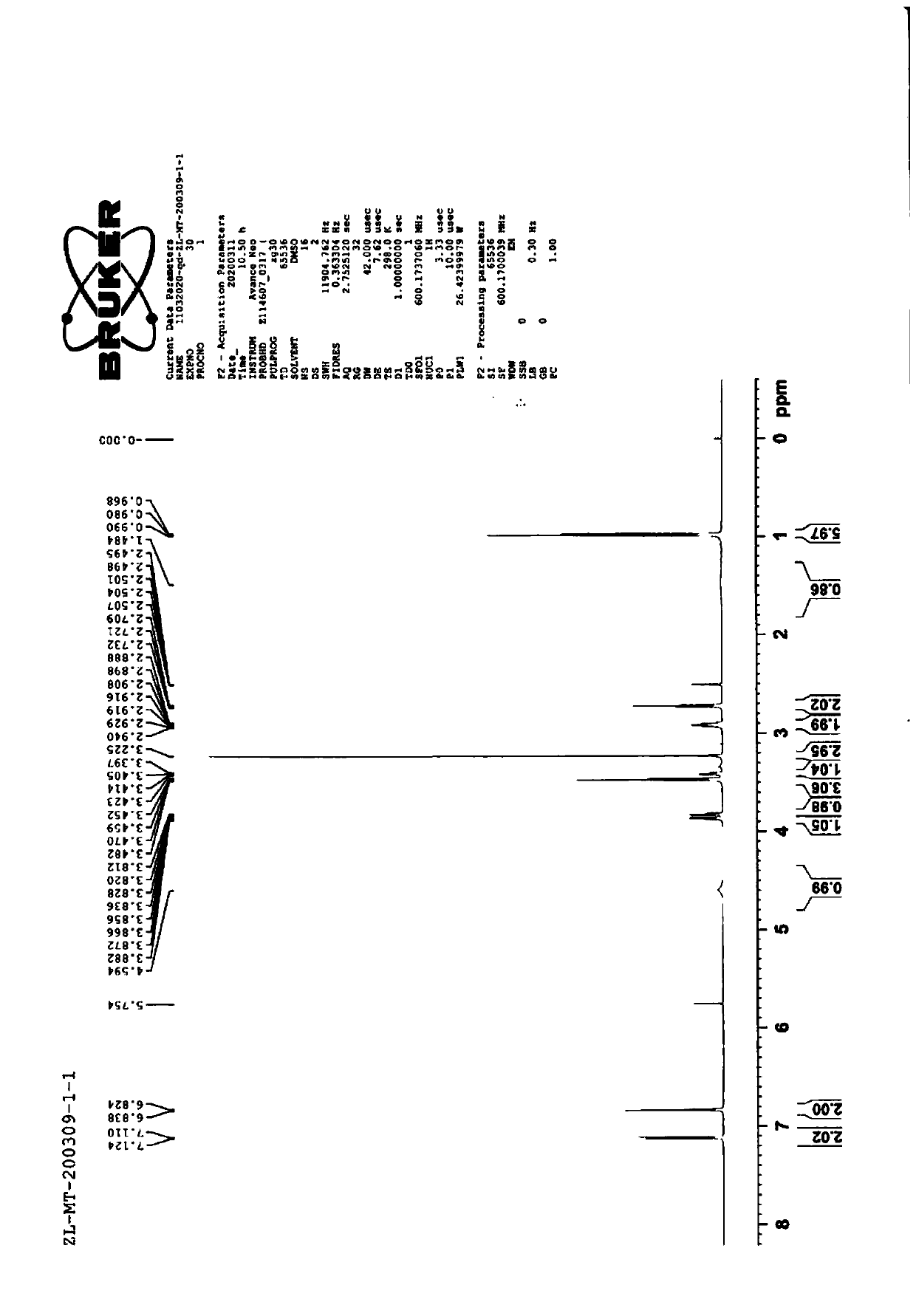

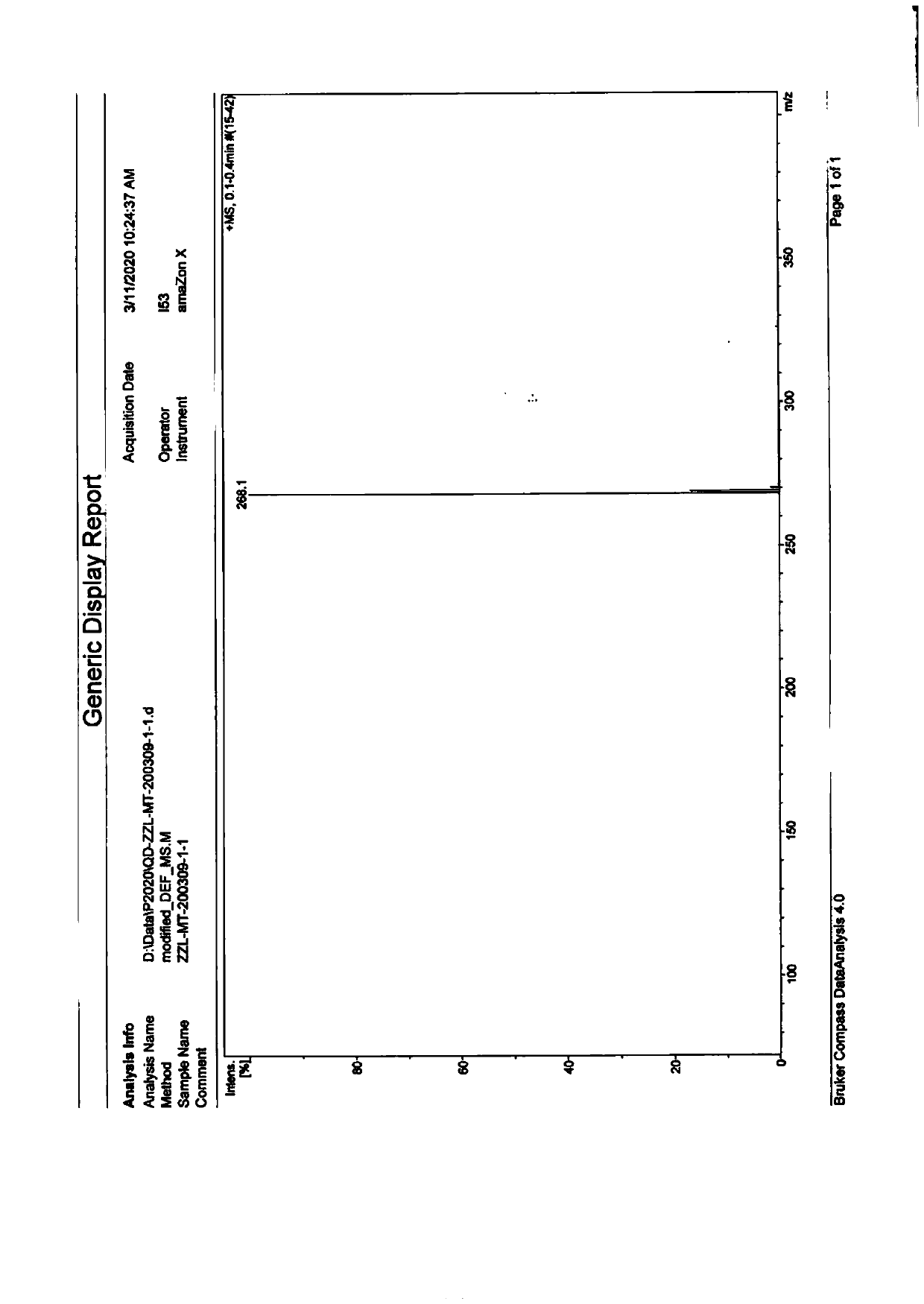

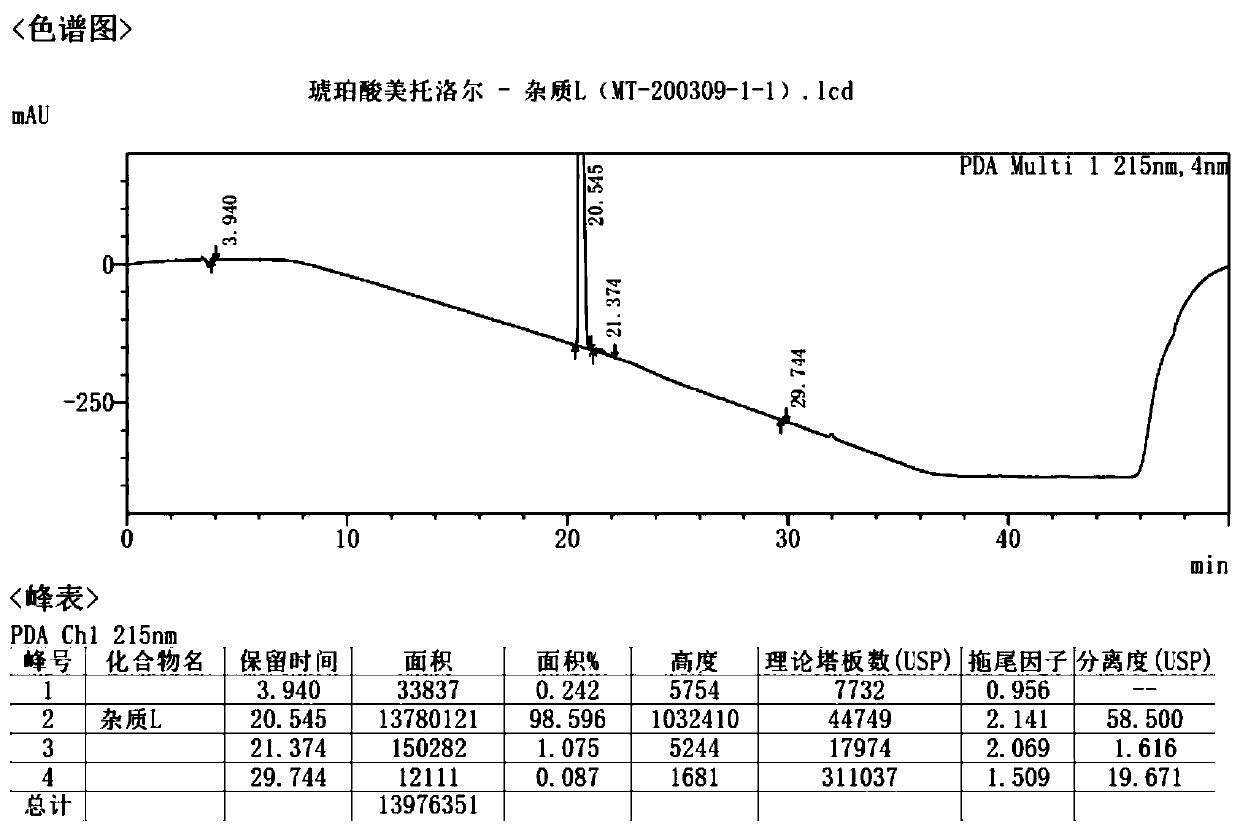

Image

Examples

Embodiment 1

[0040] Synthesis of compound 1

[0041] Dissolve p-methoxyethylphenol (1.5g, 9.9mmol) in 10mL ethanol, add it to a 25mL reaction flask, add sodium hydroxide (0.6g, 15.0mmol), stir, add epichlorohydrin (2.8g , 30.0mmol), heated to 60±2°C, stirred for 4 hours, TLC detected that the reaction was complete (petroleum ether:ethyl acetate=5:1, V / V), poured the reaction solution into purified water (30mL), and used Extracted with ethyl acetate (10 mL), kept the ethyl acetate phase, dried over anhydrous sodium sulfate, concentrated under reduced pressure and separated by column chromatography to obtain 1.6 g of a colorless oily substance, namely compound 1, with a yield of 77%.

Embodiment 2

[0043] Synthesis of compound 2

[0044] Compound 1 (1.6g, 7.7mmol) was dissolved in 10mL of acetonitrile, added to a 25mL reaction flask, benzoic acid (1.1g, 9.1mmol) was added, stirred, sodium bicarbonate (0.8g, 9.5mmol) was added, and the temperature was raised to 50±2°C, stirred for 6 hours, TLC detected the completion of the reaction (petroleum ether: ethyl acetate = 2:1, V / V), filtered to remove sodium bicarbonate and distilled under reduced pressure, the residue obtained was separated and purified by column chromatography, 2.1 g of a colorless viscous oil was obtained, which was compound 2, with a yield of 83%.

Embodiment 3

[0046] Synthesis of compound 3

[0047] Dissolve compound 2 (2.1g, 6.3mmol) in 10mL of dichloromethane, add it to a 25mL reaction flask, add pyridinium chlorochromate (2.0g, 9.4mmol), stir at room temperature, stir for 2 hours, TLC detects that the reaction is complete (petroleum ether: ethyl acetate = 2:1, V / V), the reaction solution was poured into purified water (10 mL), stirred for 5 minutes, left to stand and separated, the dichloromethane phase was retained, dried over anhydrous sodium sulfate, After concentrated under reduced pressure and separated by column chromatography, 1.8 g of a colorless oily substance was obtained, namely compound 3, with a yield of 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com