Perovskite photovoltaic cell and preparation method thereof

A perovskite battery and perovskite technology, applied in the field of solar cells, can solve problems such as battery stability degradation, achieve the effects of reducing interface defects, reducing charge accumulation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

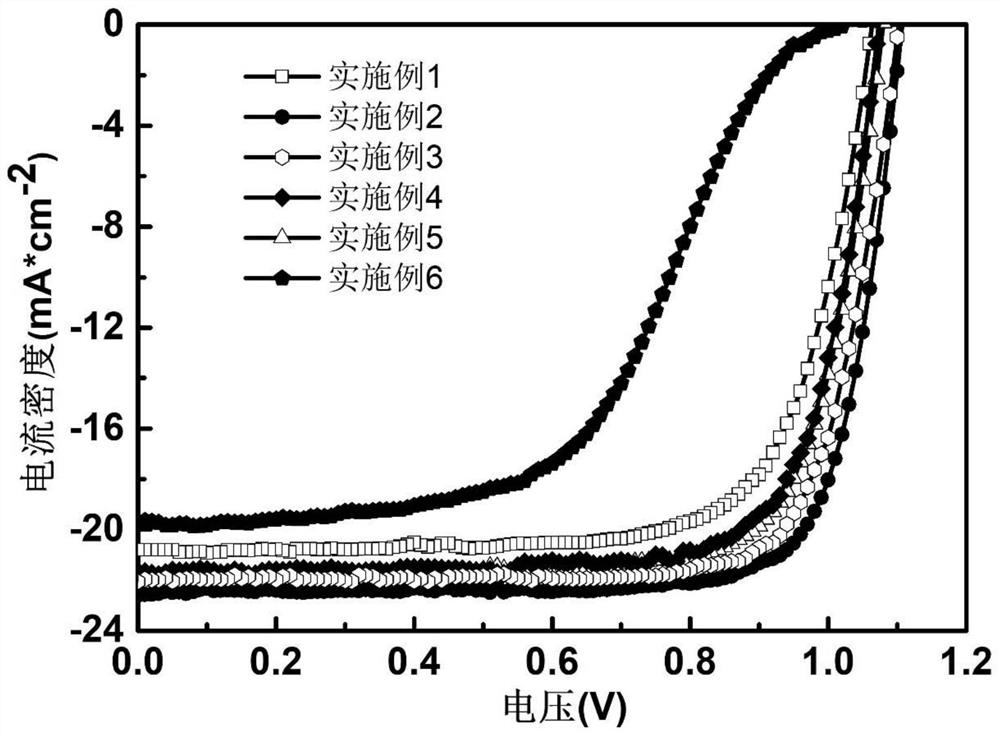

Embodiment 1

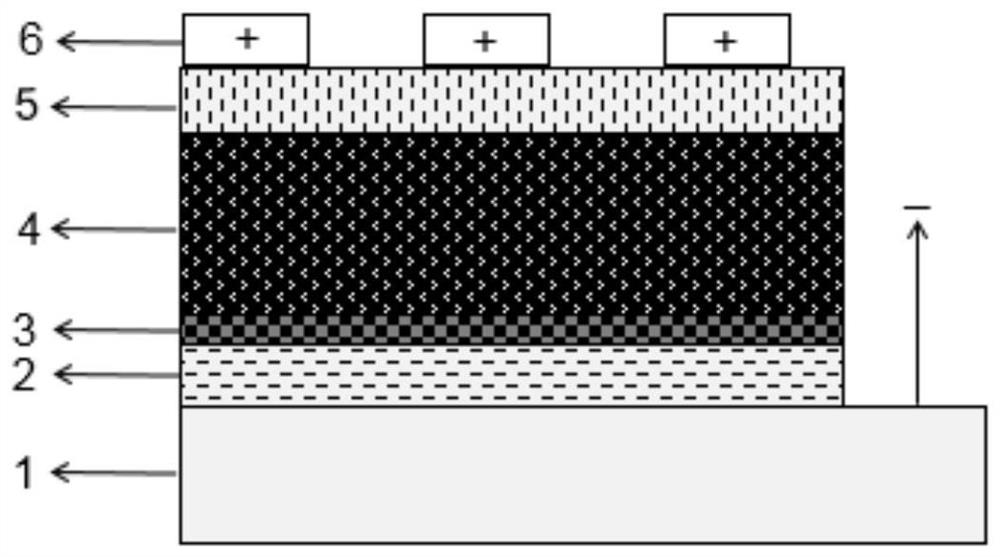

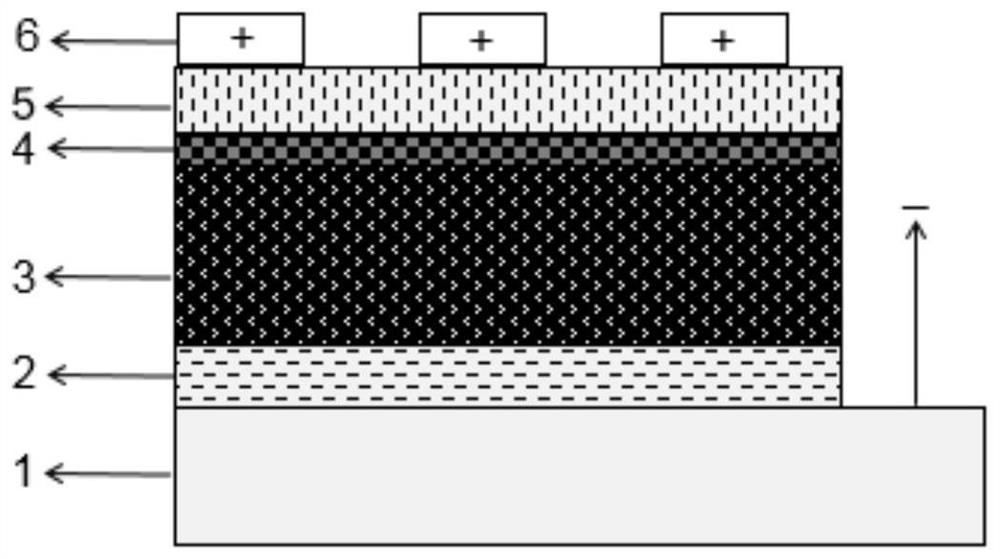

[0044] A planar structure perovskite photovoltaic cell, the structure schematic diagram is as follows figure 1 As shown, its structure includes a transparent conductive substrate 1, an electron transport layer 2, an interface passivation layer 3, a perovskite photosensitive active layer 4, a hole transport layer 5 and a metal electrode 6 from bottom to top, and its preparation method includes the following steps :

[0045] (1) Cleaning treatment of transparent conductive substrate: To clean the FTO conductive glass sheet, first soak the FTO conductive glass sheet in warm water containing a detergent (such as liquid detergent) for 20 minutes, then rinse it with clean water after repeated scrubbing; Then use polishing powder for polishing; then put them into containers containing deionized water, acetone and alcohol for ultrasonic treatment for 20 minutes, and finally put them in deionized water to rinse twice, dry them with a nitrogen gun and put them in an oven Dry at 60°C; ...

Embodiment 2

[0057] A planar structure perovskite photovoltaic cell, its structure includes a transparent conductive substrate, an electron transport layer, an interface passivation layer, a perovskite photosensitive active layer, a hole transport layer and a metal electrode from bottom to top, and its preparation method includes the following step:

[0058] (1) cleaning FTO conductive glass substrate: with embodiment 1;

[0059] (2) Preparation of electron transport layer: preparation of SnO on FTO substrate 2 Thin film, and put it into the ultraviolet ozone cleaning instrument for ultraviolet ozone treatment for 15 minutes, and quickly transfer the treated FTO substrate into the glove box;

[0060] (3) SnO on the substrate by solution method 2 Preparation of Fe on thin film 1.84 Mg 0.16 o 3 The thin film acts as an interface passivation layer;

[0061] a. Take 1mg of Fe 1.84 Mg 0.16 o 3 Add 2 ml of methanol to the particles, ultrasonically disperse twice, 30 minutes each time, c...

Embodiment 3

[0070] A planar structure perovskite photovoltaic cell, its structure includes a transparent conductive substrate, an electron transport layer, an interface passivation layer, a perovskite photosensitive active layer, a hole transport layer and a metal electrode from bottom to top, and its preparation method includes the following step:

[0071] (1) cleaning of ITO conductive glass substrate: with embodiment 1;

[0072] (2) Electron transport layer preparation: prepare SnO on the cleaned ITO conductive glass substrate 2 Quantum dot film, and put it into the ultraviolet ozone cleaning instrument, and treat with ultraviolet ozone for 10 minutes under atmospheric atmosphere and room temperature;

[0073] (3) SnO on the substrate by solution method 2 Preparation of Fe on Quantum Dot Films 1.80 Mg 0.20 o 3 The thin film acts as an interface passivation layer;

[0074] a. Take 1mg of Fe 1.80 Mg 0.20 o 3 Add 2 ml of methanol to the powder, ultrasonically disperse twice, 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com